Magnum Gaskets is cautioning technicians and DIYers to be especially mindful of the gaskets they choose due to a recent influx of imported molded gaskets with inferior rubber compounds, which will not provide the long-term service life they expect. Of particular concern is that the appearance of good quality and poor quality molded gaskets can be nearly identical, yet they will have vastly different levels of sealing ability.

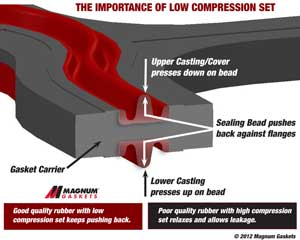

The invisible difference between premium quality gaskets and those of lesser quality is the compression set of the synthetic rubber. Compression set is the measure of how much a rubber seal loses the ability to “push back” against the sealing surfaces over a period of time, so a smaller number is better. Matt Algate, manager of Magnum’s Florida gasket molding facility explains, “Carefully selected and processed rubber compounds almost never exhibit more than 20% compression set in our tests, which are conducted according to ASTM standards.” Algate adds, “When we evaluate competitors’ gaskets that were recently sourced in the Far East, test results showing 40%-60% compression set are common with some results spiking much higher. There is no way that those gaskets can maintain a tight seal for the same number of miles as premium quality gaskets.”

The invisible difference between premium quality gaskets and those of lesser quality is the compression set of the synthetic rubber. Compression set is the measure of how much a rubber seal loses the ability to “push back” against the sealing surfaces over a period of time, so a smaller number is better. Matt Algate, manager of Magnum’s Florida gasket molding facility explains, “Carefully selected and processed rubber compounds almost never exhibit more than 20% compression set in our tests, which are conducted according to ASTM standards.” Algate adds, “When we evaluate competitors’ gaskets that were recently sourced in the Far East, test results showing 40%-60% compression set are common with some results spiking much higher. There is no way that those gaskets can maintain a tight seal for the same number of miles as premium quality gaskets.”

According to the company, more than 90% of Magnum products are designed, manufactured and packaged in the U.S.A. The complete Magnum Gasket line covers more than 80% of sales in manifold, valve cover and oil pan gasket categories for domestic and import cars and light trucks, at very competitive prices. Gasket sets contain everything the installer will need for a successful repair and every part meets or exceeds OEM standards. Sets are packaged in durable boxes with informative tri-lingual labels and installation guides.

For more information, visit www.magnumgaskets.com or call 847-580-6110.