The relationship between the cam and crank is a critical one. You might say they are heavily dependent on each other for their survival because any slip-up and their union ends in catastrophe. Locking down engines for timing service is a necessity anytime you remove the crank or cam pulley or have to replace the belt itself.

Because modern vehicles use so many electronics to control the engine with things such as crank and camshaft timing sensors, technicians need to be, as we say in the industry, “dead-on” with the timing belt alignment. The cam gear cannot be off by even a tooth, or the engine will set a DTC. The cam and crank must correlate to within a certain number of degrees set by the ECU, which could be less than 8 degrees in some vehicles. If the vehicle also has variable valve timing, it’s a little more challenging to be sure the cam is where it is supposed to be since the gear can move around on its axis and throw things off.

While timing belts have been steadily getting replaced by chains due to their longer service life, belt manufacturers have made strides to improve their belt life to more than 100,000 miles, in some cases. Even though belts will not last as long as a chain, they are quieter and often easier to line up correctly with the cam and crank locked down.

Anytime the belt is removed, the cam and crank need to be aligned to TDC No.1, which is where the marks on the crankshaft pulley line up with the pointer on the front cover. After the valve covers have been removed and the engine is at TDC, the cam(s) should line up with the correlated mark on the cylinder head or camshaft bearing cap closest to the gear. Typically, there is a notch or a raised arrow on the bearing cap so it can be easily confirmed by eye when the two marks line up or, in the case of a stretched belt, do not line up.

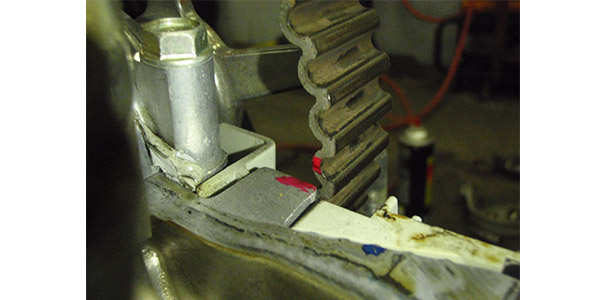

Some manufacturers make a slot on the back side of the cam or a hole on the top of a cam bearing cap to slide in a punch, screwdriver or flat piece of steel through the back to lock down the cams after everything has been lined up at TDC No.1. Special cam locking tools are also available that have locks for individual cams as well as a dual cam lock for DOHC applications.

Locking the cams, as we said earlier, is an essential step because it prevents the cam(s) from moving after the belt has been removed. If the cam does move, be sure that you have marked them so you can quickly identify where to move them back. If you have to remove a cam gear, for example, the cam may move during the removal/installation process.

After the top of the engine is locked down, the crankshaft pulley bolt and tensioner pulley need to be removed. The crank pulley can be a challenge without the proper tool to hold the crankshaft in place. Crankshaft bolts are typically thread-locked and torqued between 120-180 ft.-lbs. (or more). An impact gun can usually remove the crank bolt, but the pulley may still need to be held in place.

Certain Toyotas and Lexus V-8 engines with overhead cams use a belt that winds all the way around both banks and an idler pulley, tensioner and crank gear, so proper alignment is critical, especially if it’s an interference engine. Before installing the belt, compare the new one with the one that was removed and make sure they are the same size with the same number of teeth. Being off even a half tooth on some engines will be enough to cause trouble and means the job needs to be done again. After the belt is installed and the tensioner pin has been released, be sure to crank the engine over by hand a few times at least to make sure the timing marks line up at TDC each time.

During the final inspection, it is a good idea to watch how the belt rides on the cam gears and tensioner; use a mirror if you need to inspect the backside of the gear. If the belt doesn’t stay in the center of the gears after a few rotations, look at the tensioner for any misalignment and inspect all of the other pulleys for wobble or signs that it might be throwing the belt off center.

During the final inspection, it is a good idea to watch how the belt rides on the cam gears and tensioner; use a mirror if you need to inspect the backside of the gear. If the belt doesn’t stay in the center of the gears after a few rotations, look at the tensioner for any misalignment and inspect all of the other pulleys for wobble or signs that it might be throwing the belt off center.

Did You Know:

The most common cause of a tripped cam sensor code, according to a belt manufacturer, is the misalignment between the rear cam gear and timing belt. A DTC can be triggered with the cam gear being one tooth advanced or retarded.