Many alternator problems turn out to be nothing more than a bad connection at the alternator or a bad wiring harness.

If only battery voltage is present at the battery on a running engine, does this mean the alternator is “bad?” No, it does not. It only means that the alternator is not charging, but does not reveal why. Therefore, it does not point to a faulty alternator. All too often, the alternator is condemned by technicians due to this test alone. The cause could instead be a module that distributes the power to the vehicle and regulates the alternator.

All-season coolant used inorganic acid technology and worked great for almost 30 years.

Why do ignition systems give technicians problems when diagnosing ignition-related misfires? The answer is that some technicians use tests that might give inconclusive results or do damage to the coil or drivers inside a module.

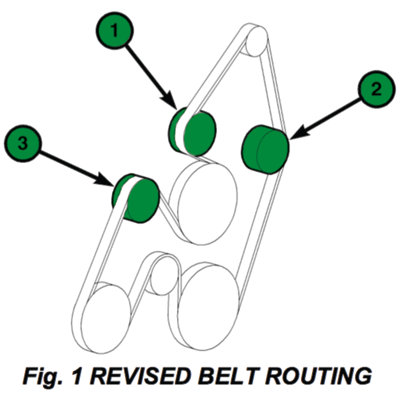

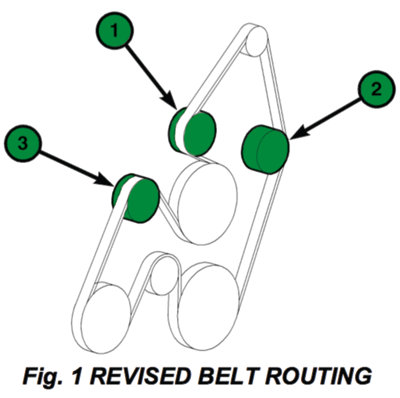

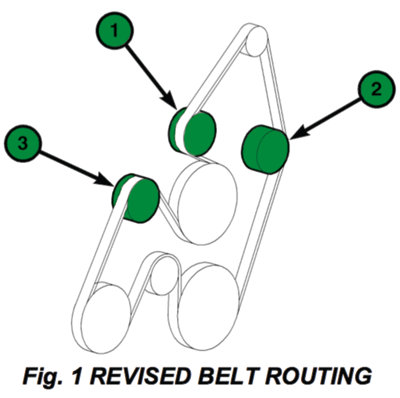

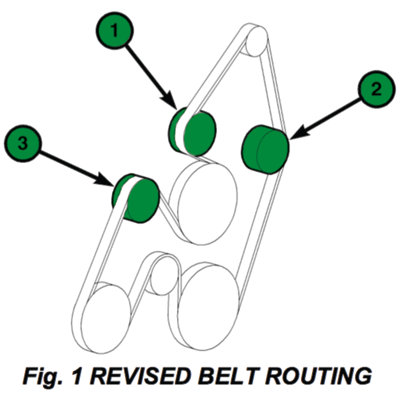

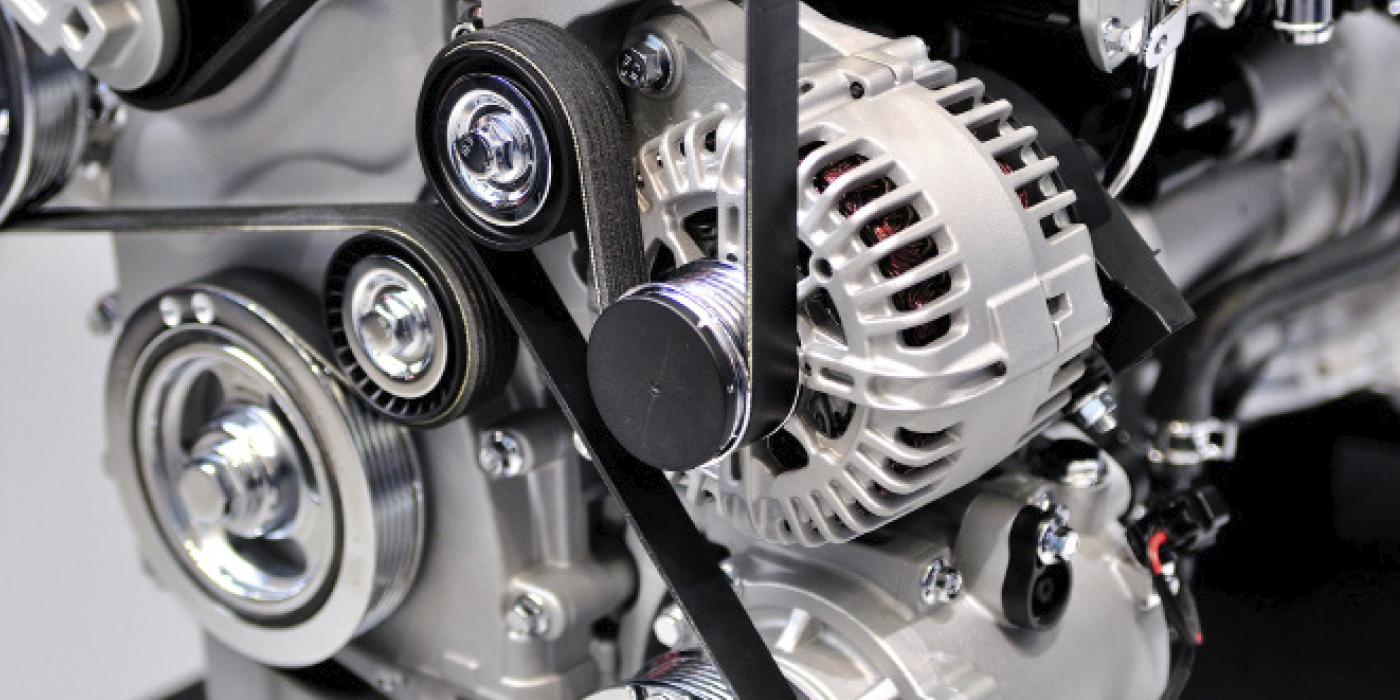

Servicing the serpentine belt on some vehicles is a tough task.

Here are six tips to use when diagnosing a vehicle with a dead battery.

Two specifications can be used to justify replacement — the condition of the additive package & the freezing point.

An accessory drive belt is always both speeding up and slowing down.

As the timing chain wears, it can change the timing of the camshaft and crankshaft.

The primary cause of these problems is that fuel and added detergents are not hitting the back of the intake valves.