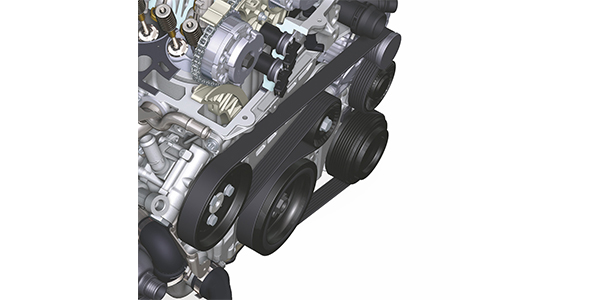

If you have looked at some maintenance schedules on late-model cars and trucks, you may notice that there have been some changes to the interval schedule for drive belts. Some manufacturers like GM are shifting to an inspection of the drive belt, instead of specifying a set replacement interval. While some manufacturers like Chrysler are recommending a 120,000-mile replacement interval in the owner’s manual.

The one thing that almost every owner’s manual or maintenance schedule specifies is an inspection of the drive belt system long before 100,000 miles. Why? In the past 20 years, the materials used in belts have dramatically improved, and drive belt systems have improved in the way they can manage slippage while using less tension. But, the one thing they can’t control is the environment under the hood. Many engine bays have turbochargers that can be brutal on belts. A belt can wear prematurely if it is operated in an area with a lot of dust and dirt.

Listen

Noise is the first sign that more components than just the belt need attention. Listen to the belt before proceeding with the rest of the inspection. The first clue of a problem is a belt squeal that is heard during engine startup. The second clue might be a belt squeal heard during parking maneuvers or during an alternator load test. Either a belt is able to grip the pulleys during these small changes in loads/speed, or it starts to slip. The more slip, the fast the rate of wear.

Look

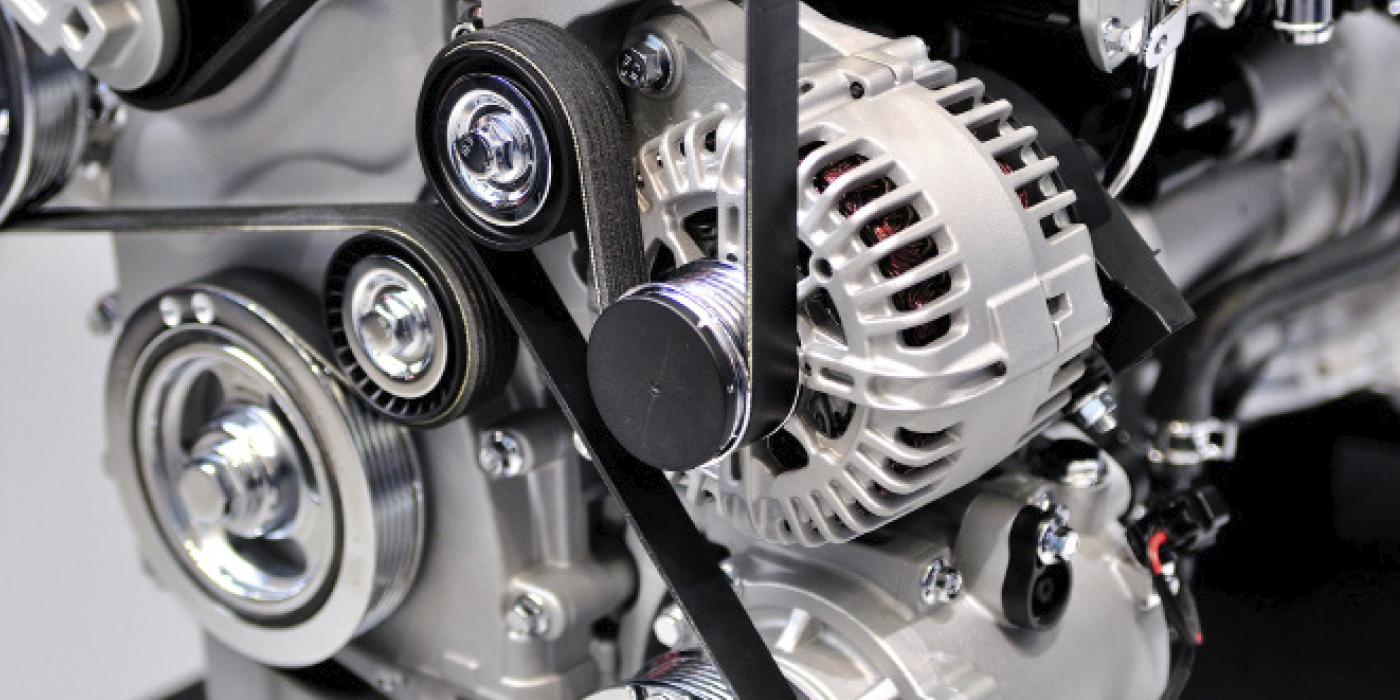

Look for erratic movement of the belt, pulleys and tensioner. If the dampener inside the tensioner is not able to control the arm, it can cause fluctuations in tension. The accessory belt may oscillate between too little tension and too much tension. The belt will slip and catch, causing noise and vibration. If the tensioner is completely worn out, the belt will slip and then catch suddenly.

Watch the belt while the engine is running. If you see a lot of movement or flutter in the belt, the tensioner is probably weak or sticking and should be replaced. Many tensioners also have an indicator mark that shows their range of travel. If the mark is not between the normal limits, the tensioner is weak or sticking, or the belt is not the correct length for the application. The problem could also be a bad alternator decoupler pulley.

Touch

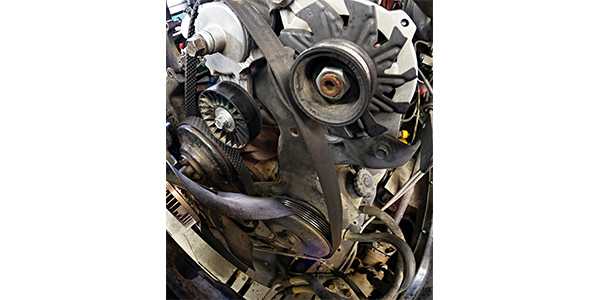

With the engine off, find the longest unsupported run of the belt and examine it. Abnormal wear like missing chunks, pilling and glazing on the grooved side of the belt is a sign there is not just a problem with the belt, but with the pulleys and connected devices, as well. In these cases, replacing just the belt does not solve the underlying problem.

Missing chunks on modern belts usually signal high underhood temperatures. The engine and also the flexing of the belt as it travels along the pulleys generate heat. Slipping on the pulleys creates friction and heat, which breaks down the materials of the belt and causes oxidation.

Measure

The walls on the grooves and the force put on the belt by the tensioner is what allows the belt to grip the pulley. Like a tire, the friction between the belt and pulleys wears away at the belt — usually on the tops and walls of the ribs. Eventually, the grooves of the pulleys will bottom out on the grooves of the belt, and then the belt will start to slip.

According to one belt supplier, as little as 5 percent of rib material loss and surface wear can affect how the belt performs, and just 10 percent belt slippage can affect the overall driveability of a vehicle. Belt manufacturers have simple gauges that can measure groove depth, overall thickness and cracks to quantify wear.

Remove

Remove the belt and look at all of the belt’s surfaces, including the back, front and sides. If the abnormal wear is in only one area, it is a sign the belt was damaged during installation, or an incident occurred where an object came between the belt and pulley. The typical sign of installation damage is rib separation from a 1- to 2-inch area of the belt. This can occur if the belt was pinched or pried into position with a sharp object.

Check Alignment

Poor alignment is the No. 1 cause of belt noise. Poor alignment can also cause premature wear, belt-miss tracking or rib skipping. It can also cause belt edge wear and fraying. Look down the side of the belt to make sure the edge does not make any bends toward or away from the engine. Any deviation you can detect with your eye is too much.

Many systems with excess misalignment can be corrected by accessory mount shimming, shifting the position of the pulley on the accessory shaft or loosening the accessory mount points and varying the sequence of tightening.

Decoupler Pulleys

When inspecting a decoupler or pulley, there are two signs that replacement is needed. First, after shutting down the engine, if there is an audible buzzing, the bearings in the pulley have likely failed. The second sign depends on whether the vehicle has a one-way clutch (OWC), overrunning alternator pulley (OAP) or decoupler (OAD).

With the inspection cap/cover removed and the center locked, turn the pulley or decoupler with the appropriate tool. If it is an OAP or OWC, the pulley can be turned only in the clockwise direction. If it is an OAD, a counterclockwise turn will reveal a noticeable increase in spring force; a clockwise turn will only have slight resistance.

The tensioner, harmonic balancer and decoupler pulley work together to keep the belt in contact with grooves in the pulleys. The three components are engineered together to match the engine. If one part is compromised, all of them are compromised, including the belt.