Applicable Vehicles: All models

Follow the guidelines outlined in this bulletin to install a new oil pump after an internal engine repair or engine short block replacement.

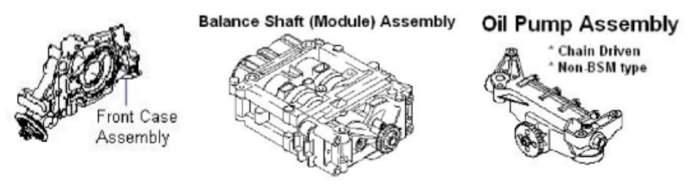

Note: A new or remanufactured engine subassembly (long block) is shipped with a new oil pump already installed, so this bulletin does not apply to the installation of new or remanufactured engines. Short engine assemblies (short block) are not shipped with a new oil pump installed and the oil pump must be ordered separately.

Inspection Procedure And Guidelines

1. Inspect the incident engine using the Engine Diagnosis Worksheet from TSB 08EM004 (Remanufactured Engine Program). Depending on the engine diagnosis, the results may not necessitate a short or long block replacement to resolve the condition.

1. Inspect the incident engine using the Engine Diagnosis Worksheet from TSB 08EM004 (Remanufactured Engine Program). Depending on the engine diagnosis, the results may not necessitate a short or long block replacement to resolve the condition.

2. After completing the Engine Diagnosis Worksheet, determine the necessary action for repair.

3. If a short block replacement has been determined as the repair action with any of the following conditions, then always replace the oil pump with a new one:

• Low or no oil pressure.

• Excessive metallic/foreign debris found inside the oil pan or oil pickup screen.

• Continuous engine knocking noise (after isolating the accessory drive such as power steering, A/C compressor, water pump, etc.)

• Engine friction damage such as piston/cylinder wall scuffing, main/rod bearing/ journal scuffing, overly worn thrust bearing, or seizing of rotating components.

• Engine overheat caused internal engine damage.

4. If a short block replacement is not required and none of the existing conditions from Step 3 have been found, refer to the following inspection points of the engine oil pump prior to reuse:

• Turn the oil pump by hand (rotor/sprocket) to confirm it can be rotated freely without much resistance. Replace if internal binding damage is observed.

• Turn the oil pump by hand (rotor/sprocket) to confirm it can be rotated freely without much resistance. Replace if internal binding damage is observed.

• Visually inspect the condition of the front main oil seal in the oil pump (for engines using a front case assembly oil pump) for wear, tear or leaks. Replace the front main oil seal if necessary to ensure a proper seal.

Note: If the front main oil seal is found partially pushed out from the front case assembly, check if there is excessive crankshaft thrust endplay.

• Visually inspect and clean the oil (pickup) screen assembly. Replace if damaged.

Inspect and retighten (if necessary) the machine screw fasteners of the oil pump cover.

Courtesy of MotoLOGIC® Repair & Diagnostics: www.motoshop.com/motologic