Hydraulic Versus Mechanical Tensioners

Hydraulic Versus Mechanical Tensioners

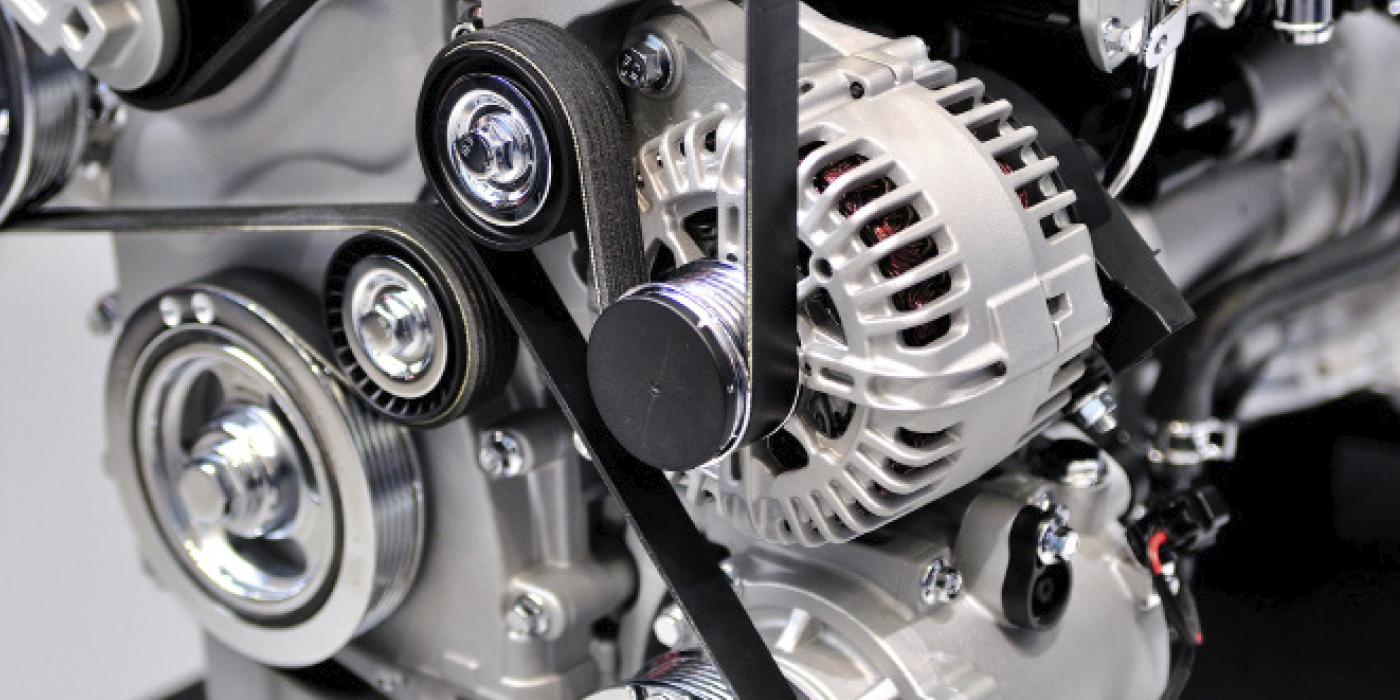

Timing belt drive systems come with a variety of tensioning methods and components. In the past, engines used a manual tensioner (or eccentric pulley) for the drives, which had to be installed and then locked in place. Over time, the belt tension would change as there was no self-adjustment mechanism for the tensioner after the initial installation. An automatic tensioner optimizes the belt tension in function and adapts to changes in the belt and engine characteristics. Engineers have designed two main systems to ensure optimal belt tension at all times. The first one is the “traditional” and most commonly used design, where a spring-loaded mechanical tensioner controls the belt tension.

The second system, less popular and more expensive, consists of a hydraulic tensioner setup.

The hydraulic system is mainly used on applications with high loads and/or angular vibrations where a mechanical automatic tensioner cannot provide sufficient damping or tensioner movement. In general, the hydraulic tensioner units need more engine space.

A hydraulic tensioner system consists of a hydraulic actuator in combination with a tensioner pulley. The movement of the piston rod of the actuator is transmitted to the tensioner pulley via an integrated or separate lever.

The hydraulic actuator works like a suspension strut, where a spring in combination with the damping feature of the oil will keep the wheel in contact with the road. In this case, the hydraulic actuator controls the dynamic belt forces while maintaining a +/- constant belt tension. It also compensates for length changes due to thermal expansion.

A hydraulic actuator typically consists of the following parts: housing (cylinder), piston rod, piston, oil, air, spring, one-way valve and retaining pin.

The piston rod can move easily in one direction (piston rod moving outward) due to the oil flowing from one side of the piston to the other via the one-way valve. High dynamic belt loads are controlled by hydraulic damping. This damping is created when engine loads force the piston rod to move inwards, displacing the oil in the cylinder. The damping is optimized for each application and is dependent on the gap between the piston and the cylinder, as well as the viscosity of the oil.

Installation

The retaining pin should only be removed after the installation of all the components (i.e., new belt, pulley, lever, hydraulic actuator). The reason for this guideline is that, once installed, the hydraulic actuator is in a vertical position and there is no risk of mixing air into the oil. The installer should always refer to the OE recommendations when doing belt system replacement or refer to instructions supplied with all Timing Component Kits.

If the pin is accidentally removed, in horizontal or inverted tensioner positions, it is strongly recommended to compress the piston rod gently while in the upright position and then install the part. The engine should be rotated a few revolutions by hand in order to ensure separation of the oil and air before engine startup. It is also suggested that after rotating the engine two full revolutions, the system be allowed to sit for 15 minutes before startup.

Advantages

Typically, hydraulic tensioners can operate with a larger range of dynamic belt lengths than mechanical tensioners. Due to the length of stroke of the actuator and the lever design, the hydraulic tensioner system is particularly suitable for large V6 or V8 applications. The high unidirectional damping characteristics make it suitable for controlling the dynamic belt behavior on applications with high dynamic loads.

Courtesy of Gates.