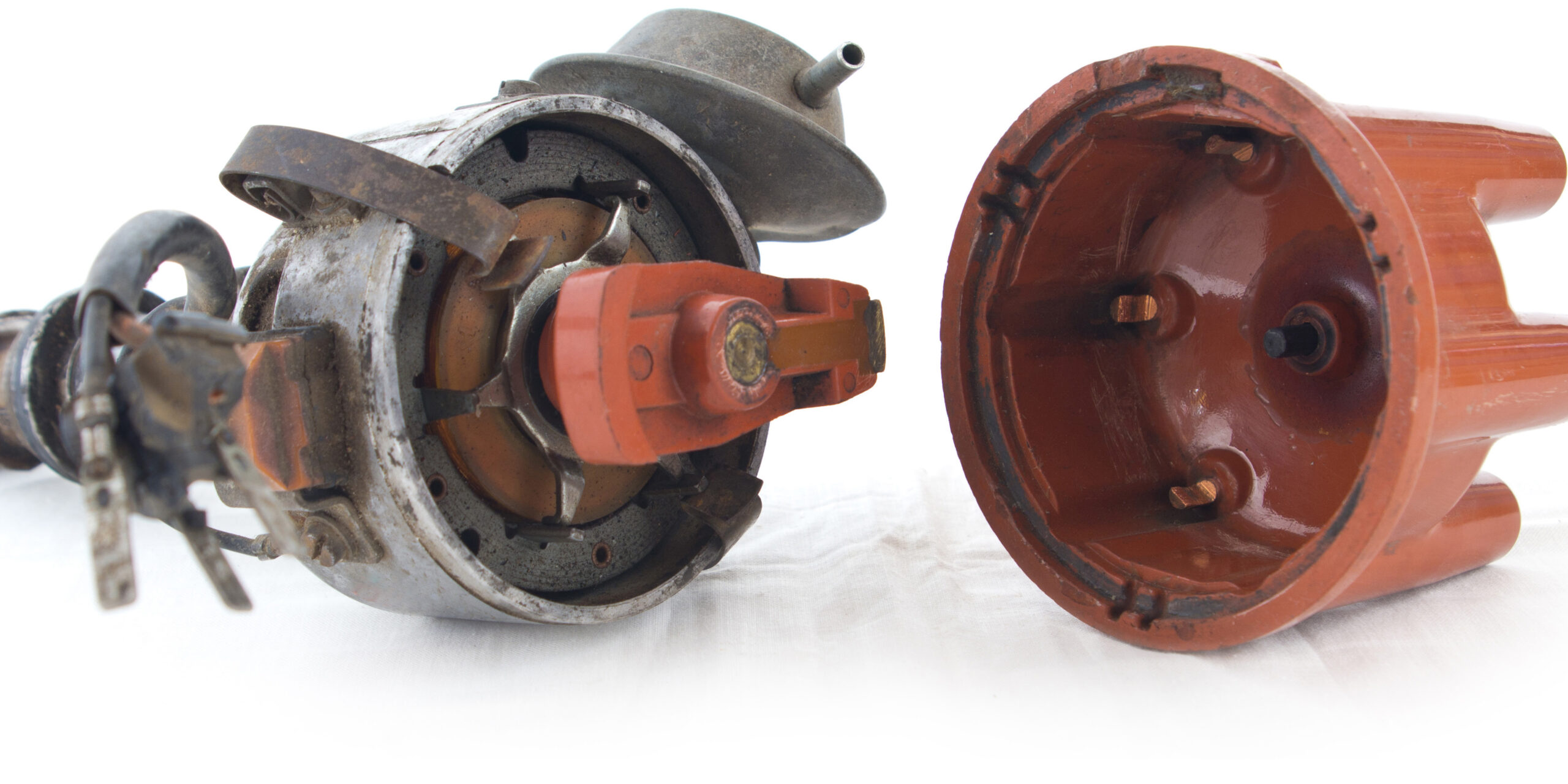

Anyone installing new spark plugs needs to be mindful of the right gap for successful ignition and optimal performance. This gap, or the proper distance between the center and ground electrodes, can be found in each vehicle’s service manual.

One of the main reasons to take extra care in this area is that spark plug gaps are a delicate balance, with proper distances coming down to a tenth of a millimeter or four thousandths of an inch. Without the right gap, the plug may not be able to ignite the air-fuel mixture or create the necessary combustion to start an engine. Too small of a gap and the flame kernel may not have enough room to expand. Too large and the voltage required from the coil may be too great.

Because spark plugs are precision-made products, any adjustment has the potential to greatly affect performance. This is especially true of iridium plugs. Even though they can potentially deliver more than 100,000 miles of ignition, 0.6mm or 0.5mm iridium finewire can be destroyed during gapping. A combination of a steady hand and a trusty gapping tool is needed to take on this task.

The Right Gapping Tool for Iridium

Fortunately, spark plug metallurgy is not the only engineering advancement in automotive ignition. The gauges used for gapping have also evolved. The original ramp-style gauge was inserted in-between the center and ground electrodes, spun along its angled surface to the proper gap and then pulled out. Long ago, this was the standard tool for the job, but it has been surpassed due to its potential for damage. Specifically, this gauge could break off the electrode or cause damage to iridium-enhanced or true iridium finewire. The right tool must be more delicate.

A wire loop gauge is the preferred gapping tool because of its combination of accuracy and damage-free operation when used properly. With a selection of wire loops and a hook, this gauge helps in measuring the gap, gently bending the electrode and then re-measuring until correct. This should be the only gapping tool used in your shop, especially when it comes to iridium finewire spark plugs.

Gapping is one of the last steps in getting customers set up with the ideal ignition products for their needs. Before you get to work installing new plugs, make sure to educate customers on the importance of premium options. Iridium is a reliable way to limit misfires and failed ignition while promoting fuel economy, long-lasting performance and overall customer satisfaction.

Autolite Iridium Ultra® Spark Plugs provide the precision and reliability of an engineered OE replacement spark plug. The highest performance offering from Autolite®, Iridium Ultra® features a laser-welded 0.5 mm iridium finewire center electrode for optimal fuel efficiency, acceleration and focused ignitability. Iridium XP offers a tested blend of iridium, platinum and palladium to precisely focus spark energy at the optimum ignition point to deliver high power, long life and exceptional value.

Autolite® has been focused on developing spark plugs for 85 years. We have done the research and put in the hours to enhance the performance, durability and ignitability of plugs for domestic and import engines. Explore the benefits of our most advanced products, our iridium spark plugs, at autolite.com.

This article was sponsored by Autolite. For more information, visit https://www.autolite.com/.