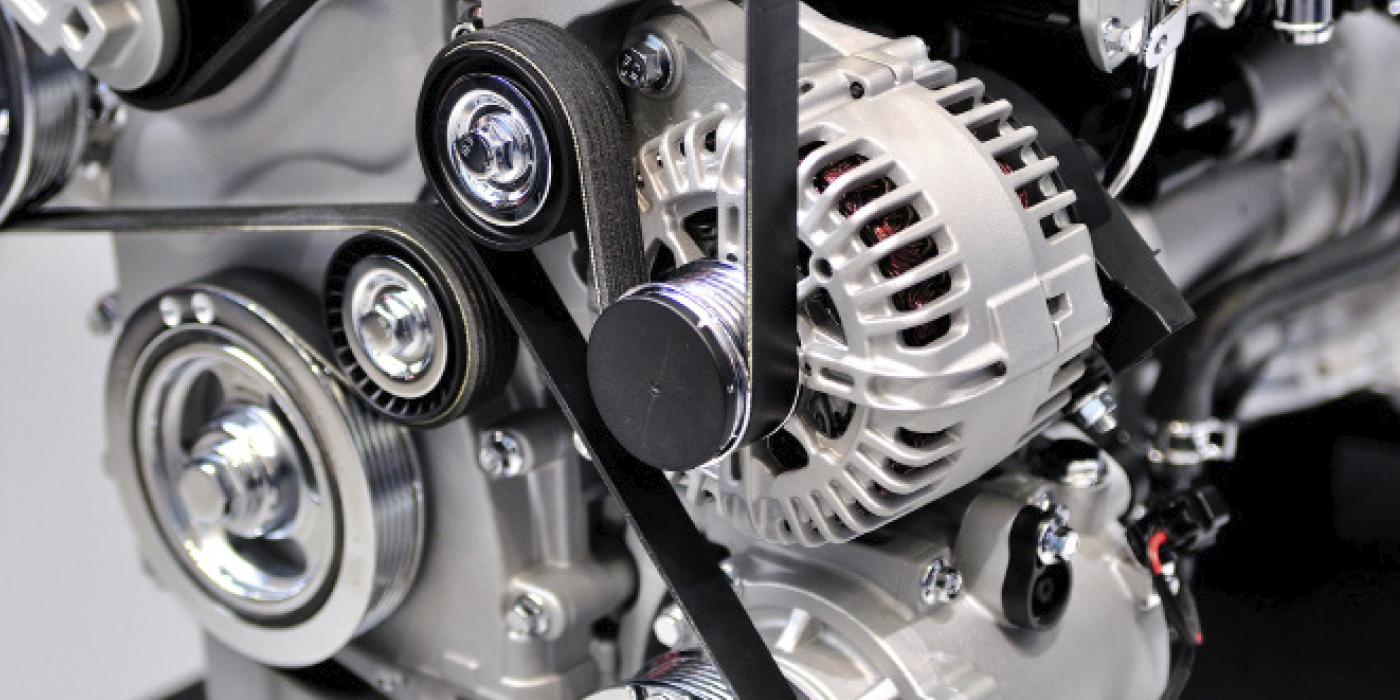

Have you ever been amazed about how complex some belt routing diagrams can be when all they are driving is an alternator, A/C compressor and maybe a power steering pump? The belt might be 8-feet long and loop around one or two idler pulleys.

On an engineering level, the design of the accessory belt drive is a balancing act of efficiency, force and vibration. The more contact or wrap a belt has with a pulley, the more force or energy can be transmitted without slipping and the less tension the belt will need. But this is not great for efficiency because it creates more friction and drag.

The design of the accessory belt also creates a balancing act for the accessories. A water pump pulley may require less contact or wrap with the belt, while the A/C compressor may have a lot more contact or wrap.

The other issue is keeping the tension on the belt under different speeds, loads and temperatures. If the tensioner is worn, the belt will slip and then catch suddenly.

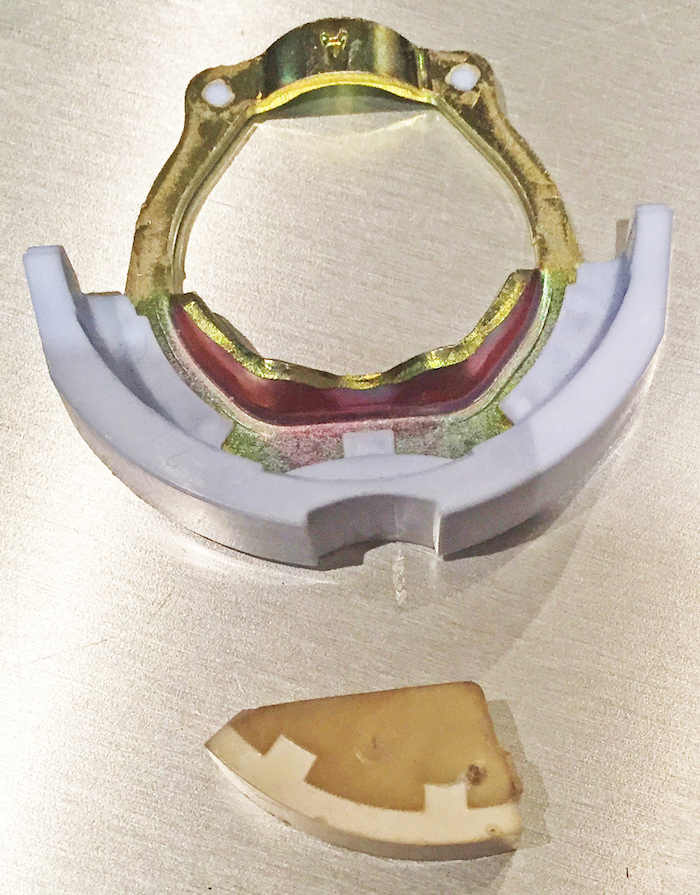

Tensioners are more than just a spring. Most tensioners have a dampener mechanism inside or connecting to the arm. This dampener prevents wild movement of the tensioner’s arm and pulley. This helps to keep the belt tension within specifications as the speed of the crankshaft and loads change.

This is the dampener section found inside a tensioner. It resists the compression and rebound of the spring.

The tensioner dampener is a sacrificial part that will wear out over time. When it does, this is when rapid changes in the belt tension occur. This can be seen through belt flutter and even excessive movement of the tensioner.

If the dampener is not able to control the tensioner arm, it can cause fluctuations in tension. The belt may oscillate between too little tension and too much tension. The belt will slip and catch, causing noise and vibration.

This can cause a change in crankshaft speed that can be severe enough to cause the engine management system to think that a misfire just occurred.

The length of a belt run can change the harmonics of the belt drive system.

Modern crankshaft position sensors measure more than the position of the crankshaft, they measure changes in the speed of the crankshaft caused by combustion events. Over the past decade, crankshaft and camshaft position sensors have become more sensitive and accurate in detecting these changes. These sensors can even detect clutch engagement in an automatic transmission and small changes in traction.

Additionally, these sensors can detect changes in the loads on the drive belt and how the engagement of the A/C compressor can change crankshaft speed. Under normal conditions, the engagement of the compressor is below the threshold of a misfire.

One A/C clutch engagement incident will not set a P0300 code. But, if enough occur and it is above the threshold of the monitor, a code will be set.