Head lift is not the whole head that is lifting from the block, but is a distortion in specific areas of the head and block interface where the head gasket is installed. This distortion can damage the head gaskets and head bolts.

Head lift is not a constant running condition, but occurs in milliseconds under the high-stress conditions where the greatest combustion chamber pressures are experienced. As the incidents of head lift add up, the head gasket and fasteners will be fatigued and eventually damaged.

If you can’t see head lift or measure it, how do you prevent it from happening? The solution is to understand what you can and can’t control.

What You Can’t Control

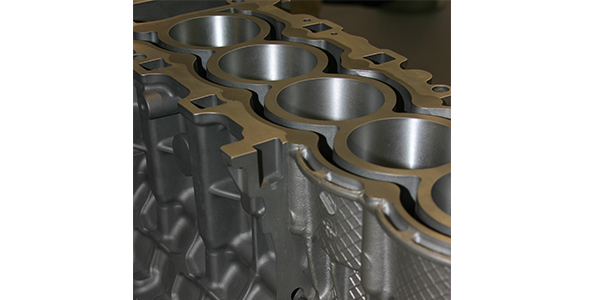

Late-model engines have increased compression ratios to new levels. During the past decade, compression ratios have risen from a mild 8.5 to 9:1 to an average of 11.5:1 to 12:1 for most naturally-aspirated production engines. For turbocharged engines, the compression ratios have risen from an average of 8.0:1 to an astounding 9.5:1-10:1.

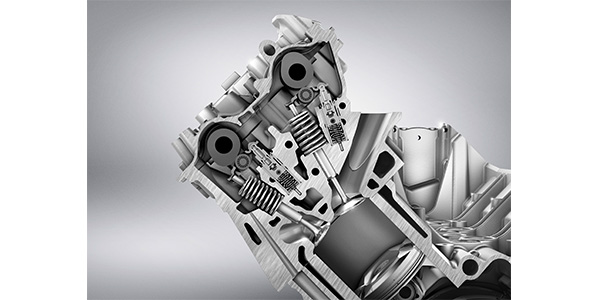

These high compression ratios are possible because the air, fuel and spark are tightly controlled. Most modern engines dance on a razor’s edge between a lean combustion event and a misfire. This edge is where the most power, efficiency and lowest emissions can be reaped.

Some direct-injection engines can run air/fuel ratios as high as 65:1 for limited periods. Unfortunately, these air/fuel ratios are where the peak combustion pressures and temperatures are experienced by the engine.

The other factor you can’t control is the design of the engine. Technicians and engine builders can’t monitor how the head is cast or the design of the deck of the block. But, there are replacement gaskets, head bolts and other parts that improve the factory design.

What You Can Control

The key to preventing head lift is to control incidents that cause high cylinder pressures and temperatures. If a head lift problem has created a head gasket problem, you can control the surface finish, gasket selection and clamping forces.

Head lift is not a constant condition. It typically occurs when factors fall outside of normal combustion. These conditions include pre-ignition and lean combustion events. Both conditions can cause sudden spikes in combustion chamber pressures.

Another factor you can control is the installation of the gasket. Head gaskets can also leak or fail if the head bolts are not tightened in the proper sequence or stages, or to the recommended torque value and/or angle.

When engines start making more power, as is common in performance applications, you have more liftoff on the head and loss of load on the gasket. Therefore, gasket makers have to determine how much load the gasket can handle, how thick does the center need to be, and should extra beading be used around the combustion chamber to increase the load. All those issues start to crop up as you move away from stock replacement applications, say gasket experts.

The head and block joint is the most difficult to seal on an engine, and therefore gets a lot of attention from gasket makers in research and design. Part of the OEM attraction to multi-layer steel is that it doesn’t compress and stay compressed like a composite gasket. An MLS gasket acts more like a spring that seals two moving parts. Manufacturers say that MLS gaskets have continued to gain dominance in the market in large part because the OEMs now use them in the majority of engine applications.

Many aftermarket MLS head gaskets can handle up to 60 to 70 micro inches roughness average (RA). Even so, the recommended finish for some aftermarket MLS gaskets may be 30 RA or less depending on the application and the thickness of the rubber coating on the gasket. Most OE MLS gaskets have a relatively thin outer coating and require mirror-like finishes on the block and head deck surfaces that are usually 20 RA or less.