Models

2006-2015 GM Passenger Cars and Trucks equipped with 6L80 or 6L90 Automatic Transmission (RPO MYC or MYD)

Condition

After installing service pump cover P/N 24248573, a transmission may have low line pressure. If the low line pressure is not identified and corrected, clutches may be damaged during operation.

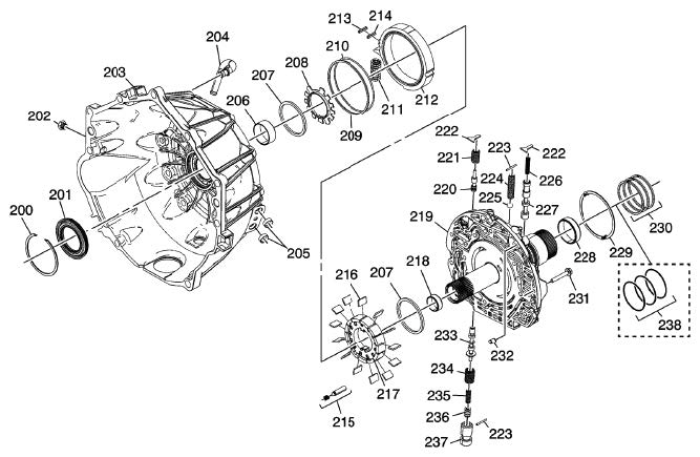

This condition may be caused by Rust Inhibitor material in the service pump cover sticking the pressure regulator valve (#233), isolator valve (#236) or by plugging the small orifice (#5) in the isolator valve sleeve (#237). The RI that can cause an issue is a thick, waxy substance.

Repair Procedure

Inspect the service pump cover and pressure regulator valve for signs of RI that may prevent the pressure regulator from operating correctly before installing the pump cover.

The pressure regulator isolator sleeve (#237) can be removed by pressing inward and allowing the pin (#223) to drop out of the cover. After removing the isolator valve sleeve (#237), the isolator valve (#236) can be removed from the sleeve. The orifice (#5) in the isolator valve sleeve (#237) should be checked for plugging.

The pressure regulator isolator sleeve (#237) can be removed by lightly pressing inward and allowing the pin (#223) to drop out of the pump cover. After removing the isolator valve sleeve (#237), the isolator valve (#236) can be removed from the sleeve. The small orifice (#5) in the isolator valve sleeve (#237) should be checked for plugging.