Models affected: 2006 and prior General Motors cars and light-duty trucks, 2003-’06 HUMMER H2, 2006 HUMMER H3 and 2005-’06 Saab 9-7X.

When servicing a vehicle for any type of customer concern — such as miscellaneous DTCs, intermittent driveability concerns, hard start, no start, incorrect gauges, inoperative air conditioning systems, service engine soon lamps illuminated, 4WD lamp illuminated, instrument panel gauges inoperative or cruise inoperative — the following steps are imperative. Inspect and ensure the integrity of all related wiring harness connectors. If the wiring harness connectors are not properly put together or engaged before they are locked together, numerous types of intermittent conditions may occur, which may include any of the symptoms listed above and possibly others.

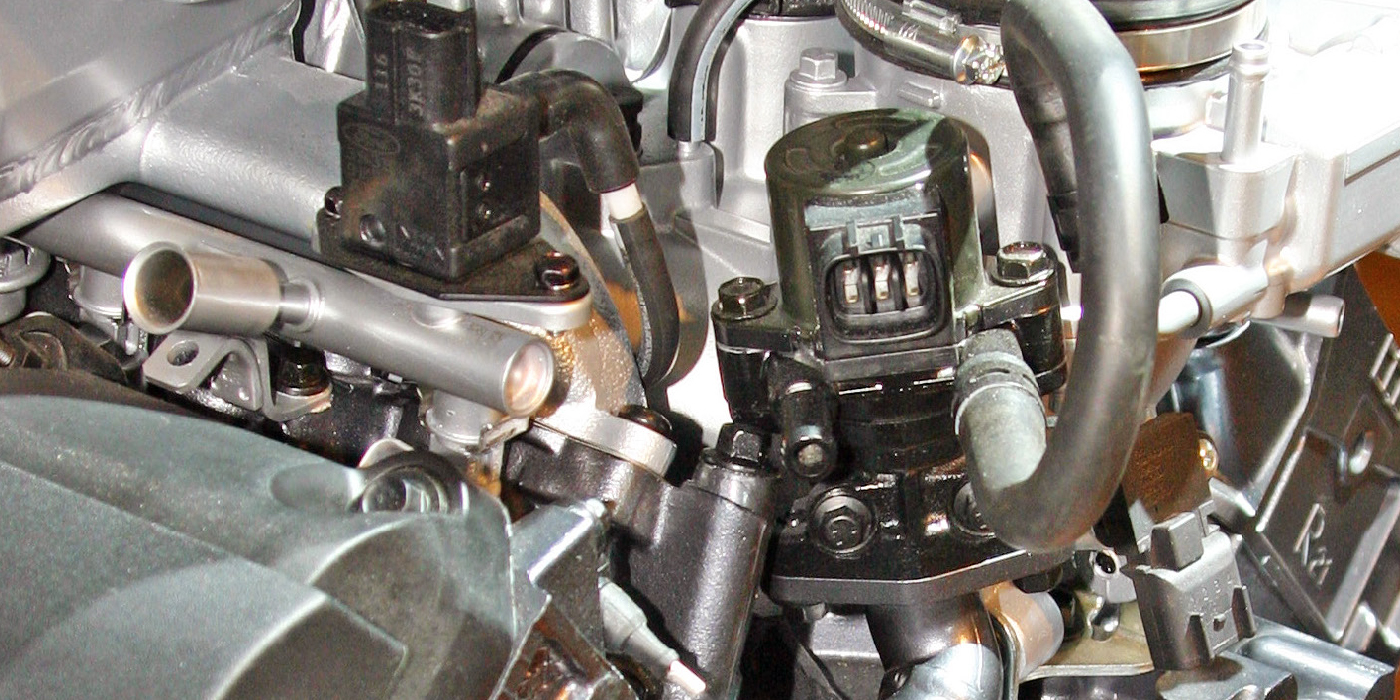

The first step in any type of electrical diagnosis is a visual and physical inspection of the wiring harness connectors for integrity. Many times, the vehicle may be repaired just by disconnecting and reconnecting the connectors. As with all repairs to wiring harness connectors and terminals, a pull test of the terminals within the connector should be performed. A pull test is performed by inserting the proper size terminal test tool (not a paper clip) into the terminal to determine whether or not the terminal is making good contact, or whether the terminal has been damaged from the prior improper connection or lack of connection.

Note: Most terminals used in current module connectors (ECM, BCM, EBTCM and the like) are small 0.64 mm sq. terminals and can be damaged by probing with the wrong tool.

The J 3561 6-64A or B probe has been designed for these terminals that may be both a round or square design. For example, if the Connector C2 of the engine wiring harness to the powertrain control module (PCM), for the 2.2L-equipped Cavalier or Sunfire is not properly seated into the PCM:

• The cam lock lever may close, however improperly;

• The cam lock lever may even snap out of position; or

• The vehicle may have an intermittent condition with any one of the components which are controlled or monitored by the PCM.

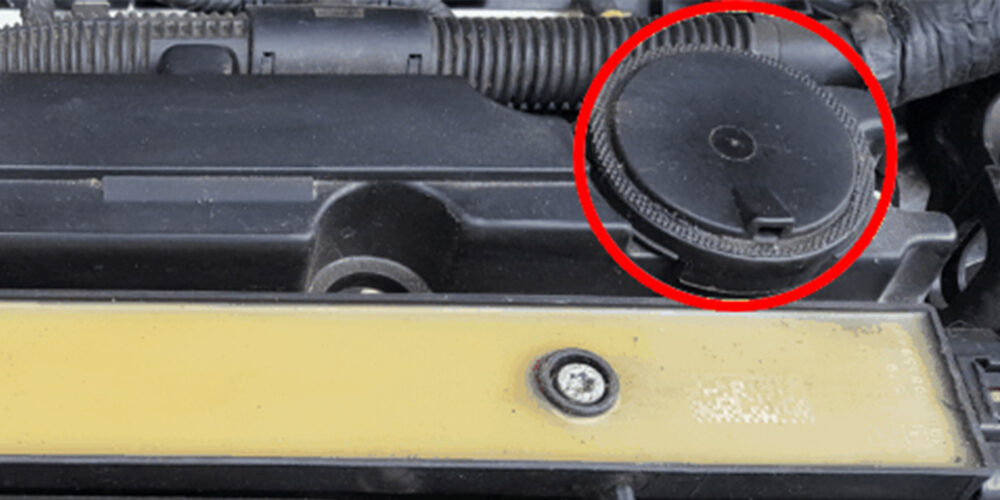

The cam lock lever is designed to pull (or assist) the connector into its final position once it has been pressed straight into the PCM header past the initial detent, allowing the lever to be moved into the locked position. It is not only a retainer, but an assist during the connection process. When the wiring harness connector is properly connected to the PCM, a snap will be heard when the connector is in position to be fully seated. The cam lock lever may then be closed. The cam lock lever will then do its designated job as both an assist and to ensure the connector does not come apart due to vibration or other types of conditions found in vehicles as they travel down the highway.

Remember, if a terminal (metal) or the connector (plastic) is damaged, they should be replaced. DO NOT replace the complete wiring harness assembly. Some harnesses are now on order restriction since most harness damage can be repaired.

Terminals and terminal removal tools are in the J 38125 Terminal Repair Kit and pigtails or complete connectors can be obtained through normal parts ordering procedures or from GMSPO and Saab PDC along with tape or conduit.

Courtesy of Mitchell 1.

For more information on Mitchell 1 products and services, automotive professionals can log onto the company’s website at www.mitchell1.com.