Is your balance stuck in the past?

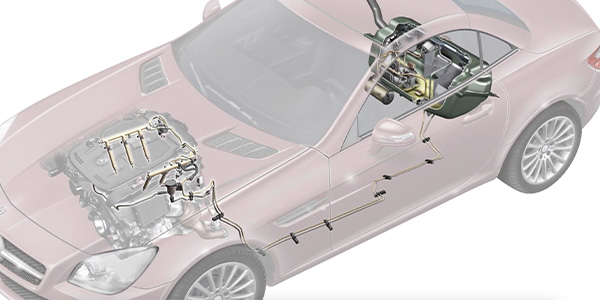

In the past decade, we have seen the demise of the stamped steel wheel as the standard wheel. Not only has this affected the hubcap industry, but wheel balancer manufacturers as well. Many of these standard equipment alloy rims have a total lack of a flange for clip weights. They also have expensive finishes that are prone to marring and any weight sticks out like a sore thumb.

It gets even worse when your balancer is asking for a lot of weight. You feel even worse when you consider that lead weights are on their way out and more expensive alternatives like steel and zinc, will soon be on the shop supplies ordering list.

So who is to blame? It would be easy to blame modern wheels. But, it goes deeper and involves your balancer’s capacity to understand what the chuck is clamping down on.

Wheel balancing is probably one of the most difficult automotive concepts to understand. But, it is one of the easiest malfunctions to experience. Just like brake rotor runout and thickness variation, every vehicle has limits to were the drive can feel the imbalance.

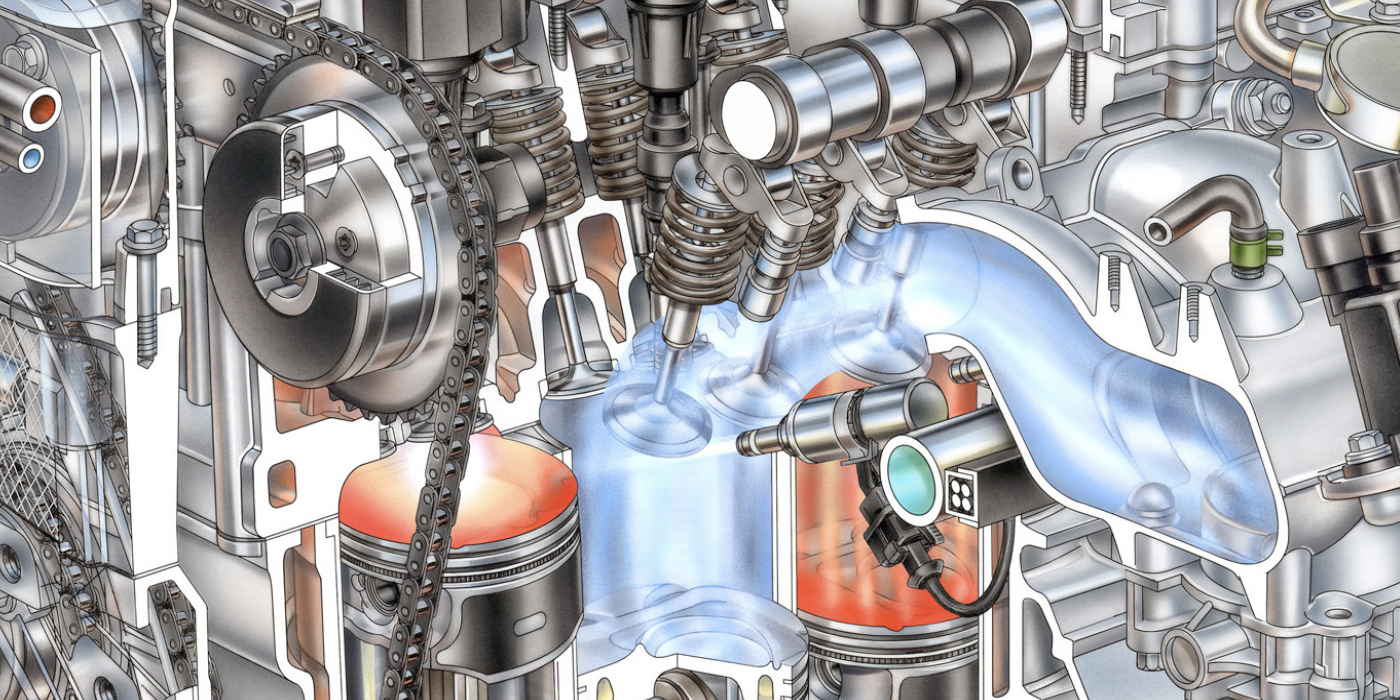

Lets get something straight about dynamic balancing. The phrase “dynamic” is a marketing word thought up 30 years ago. The word “dynamic,” in this case means active or driving. This means the balance is calculated while the wheel is turning. A “dynamic balance” is designed to correct for static (up and down) and couple (shimmy or side-to-side forces) forces.

All balancers measure static and dynamic forces. It is up the software and other measurements to determine the location and how much weight should be applied.

Some balancers calculate the magnitude of imbalance by comparing the measured static and couple forces against a single, fixed tolerance that is based on the acceptable amount of static force for a standard-size wheel.

In the cases where a wheel is larger and heavier than the standard-size wheel, the fixed aspect of the some balancing tolerances renders the balancer incapable of properly evaluating the larger specifications of some modern wheel designs. This could create a threshold that can be too loose for static-force imbalance.

Another variable in the equation is weight placement areas on some alloy wheels. The reason why alloy rims are sometimes difficult to balance is that correction weights are typically mounted closer to the center and further from the flange when compared to steel wheels. This is further compounded when you consider that wheels are increasing in diameter and mass of the wheel.

When it comes time to put the correction weight on the display, some balancers can become confused when they are trying to correct for static and coupled forces on some wheels. This is because the balancer is stuck with one tolerance. The operator may also spend time to attaching unneeded tape or adhesive weights.

It gets even worse when the couple force is so small, that the technician ends up “chasing” the weight value with repeated correction weight placements and check-spins. This is because when the balancer makes its calculation for weight placement to correct for static and couple forces, it is trying to get it within 0.29 ounces, or the amount of the smallest 0.25-ounce weight, plus .04 of an ounce thrown in for real-world variables like sensor error or weight defects. This extra weight is hidden from the operator in a “blind.” This could leave a residual static imbalance in the assembly even though the wheel has been “zeroed out.”

Such flaws in the traditional balancing method cost shops money with needless correction weight usage, wasted labor time and potential customer comebacks.

One new methodology in the world of balancers evaluates static and couple forces independently with separate imbalance tolerances. Each tolerance limit is set based on the amount of force needed to induce a noticeable vibration on a given wheel assembly depending on its mass. This is done through measuring how much energy it takes the motor to spin the wheel.

This means that it puts the appropriate emphasis on the appropriate force and calls for correction weights only when a force exceeds the limit that will cause a noticeable vibration. This is because the method recognizes that not all wheel assemblies are the same size and automatically adjusts the tolerances to more accurately determine imbalance.