From ENGINE BUILDER magazine.

When it comes to a motorsports and racing background, few people have a pedigree like the one Reese Cox of MTI Racing has. Reese began his journey in motorsports as a young 15-year-old in the drag racing scene. In 1988, he went to work for Lou Gigliotti on his Corvette Challenge cars team and then moved to an IMSA Corvette team two years later in 1990 by joining Tommy Morrison Motorsports, and his career was officially kick started.

“I wanted to join a pro team,” Cox says. “I got an opportunity to work with Morrison Motorsports out in Sonoma, CA, so I went out there and became a crew guy. In ‘93, I became the crew chief. Between ‘93-‘94, we had lots of victories, had a car on the cover of Motor Trend magazine, won the SCCA National Championship in GT-1. In ‘94, we had the highest finishing Daytona 24 Hours that Tommy Morrison ever had in his 30-year racing career.”

Reese was on the rise, and that sparked a joint venture between Reese and Tommy Morrison to open a Mobile 1 service center in the Atlanta area, as Mobile 1 was the team’s main sponsor.

“We did a lot of trips to Atlanta to figure out where we would want to build a shop,” Cox says. “I went to car shows and cruise nights and race tracks to figure out geographically, where we wanted to set up this Morrison Motorsports Mobile 1 shop. I did all the homework and when we got down to the 10th hour to make a decision, Tommy backed out of the deal.”

While not having Tommy involved was a blow, Reese knew he could make it happen and decided to do the deal on his own. In 1994, he moved from Albany to Marietta, GA and started MTI Racing.

Fast forward through lots of track days, lots of championships, track records, and all kinds of different racing – drag racing, standing mile, quarter mile, road racing, track days, endurance racing, etc. – when Ernie Elliott came to Reese with a special request.

“Ernie Elliott came to me in 2014 and basically said he was tired of running his shop and wanted me to help,” Reese says. “I told him I’d love to, but I already had a 24-hour-a-day, seven-day-a-week job running MTI. I turned him down on the first offer.

“He came back a few months later and said, ‘I’m going to give you an opportunity to come in here, take over the entire shop and become the general manager. You take care of all the profit and loss and I’ll mentor you and I’ll sell you everything I’ve got.’ That was what changed my mind.

“One of the cool things and one of the reasons I agreed to it is that I’m still working with the crew that has been with Ernie Elliott through all the heyday of Bill Elliott. We still have the same cylinder head guy who ran the 212-mph qualifying lap at Talladega. Our CNC machinist who works here is a genius and it’s the only job he’s ever had right out of high school. The people I inherited was another part of the story and part of the reason I decided to leave my 24/7 job and acquire another 24/7 job in addition to it.

“The people are the key. There’s no way I could do this otherwise. The people and the knowledge here and the help that Ernie has given me has been something beyond what I dreamed of as a kid.”

For the past six years – 2014 to now – Reese has been slowly but surely buying Ernie out and transitioning Ernie Elliott Incorporated into MTI Racing, which is a 25-year Corvette business based in Marietta, GA. This year in January, Reese decided to consolidate everything into the larger facility up in Dawsonville, GA to put everything in one location with more efficiency, a better location, a bigger shop, more capabilities, and expansion potential.

“We had 12,000 square feet in Marietta and now we’ve got 35,000 square feet up here in Dawsonville,” he says. “Now we work on all the same small block Ford stuff that Ernie had been working on for the last 40 years. We retained a lot of his customers. We do a lot of Dodge R5 engines that used to be in NASCAR until Dodge pulled out a few years ago. Whenever that happened, Ernie was building engines for Chip Ganassi, but prior to that, Ernie had been building engines in the background for Roger Penske too. A lot of the engine stuff was being developed here.

“Part of the deal that I did with Ernie is I bought out his Dodge R5 inventory, which we have the world’s largest Dodge R5 NASCAR engine inventory – for what that’s worth. We still do a tremendous business on Dodge R5s. That engine is such a great platform. It’s found its way into several different types of venues, like SCORE off-road, trophy trucks, drag race, road race, vintage cars, and stock cars. The engine is still pretty popular. I do business now with people all over the United States, in Germany, Sweden, Australia, New Zealand, and all over the world.

“We still have a pretty good small block Ford business from Ernie’s Ford days. The interesting thing that’s happened in the last six years since I’ve been up here, is that MTI Racing in Marietta was pretty much a late model GM shop. We worked on mostly Corvettes, but also Camaros, trucks, Cadillacs, Pontiacs – and so we started a core business up here of building the LS platform. Then in 2015, the LT platform started to come along and now we started to get into that, and then about a year and a half ago, we started getting into the Dodge Hemi stuff.”

Today, the day-to-day business through MTI Racing is about a half mix of pushrod, carbureted V8s and fuel injected, late model V8s. The shop’s late model engine stuff is targeted for drag racing and road race, while the shop’s carbureted stuff is for hardcore racing.

As it stands now, MTI Racing has seven full-time employees and has more engine building capabilities in-house than you could even wrap your head around.

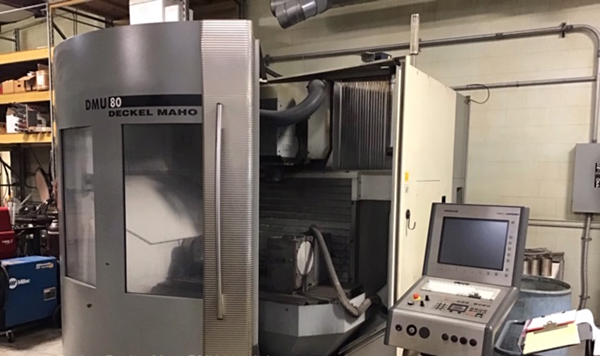

“Anybody that comes here to visit thinks about Ernie Elliott from back in the ‘80s and they think they’re going to come into an old, rundown shop with old equipment,” Cox says. “When they get in, their jaw drops because everything is current and modern.

“We were always building our engines in-house at MTI, but I never could get consistent machine shop quality from our machine shops that we were using. About 10 years ago, I brought all that in-house down in Marietta and we started doing all of our engines in-house and have been ever since.

“When I came up here in 2014, Ernie had almost the identical equipment up here in Dawsonville that I had bought in Marietta. Over the last six years, we’ve transitioned all of that work away from Marietta to up here in Dawsonville. With Ernie Elliott’s help, our street car engine programs moved up quite a bit from where they were. We were one of the better shops around, but now I feel that we’re about the best LS, LT and Hemi machine shop that you can go to.

“We have three engine dynos, a chassis dyno, a shock dyno and a valve spring dyno. That’s the thing that’s so incredible about this place is just our capabilities here. From CNC machining to fabrication to welding to anything needed for a machine shop, we have it. We even have an in-house magnaflux.”

MTI Racing’s transition to the larger shop in Dawsonville, took over five months, but it was well worth the effort and Reese is excited about the new business.

“We have such a devoted following that we’re now 60 miles north of where we were, and we have not seen any decline in our business,” he says. “In fact, we’ve actually seen increases, so I’m very enlightened and happy about that chain of events. All of our new business is coming from word of mouth so far.”

One of the big reasons for that word of mouth has been MTI’s engine packages for the LS, LT and Hemi engine platforms. All three packages come in three stage options for different horsepower levels from 550 hp all the way up to 1,000 hp.

“Our bread and butter on the car side of things are these stage packages – stage one, stage two and stage three,” he says. “We have a progression of packages so customers don’t have to bite the bullet for the 1,000 horse all at once, or ever. We’ve got horsepower packages that start at 550-700 hp, then 750-850 hp and then 1,000 hp, but we try to build for whatever the budget is. The way we do that is have an in-depth conversation with the customer about what their goals are, so that we custom tailor the package for their needs or wants.”

While the customer has several options, MTI has placed much of its R&D work into the 1,000 horsepower packages, and specifically for the Hemi option.

“The new watermark for street cars is 1,000 horsepower, so I set about developing reliable, 1,000-horsepower packages,” he says. “The hottest thing going right now for us is the expansion of the Hemi business. Here in Georgia, you see 10 Dodges for every Corvette or Camaro driving around.”

To make sure the Hemi engine package is up to snuff, MTI puts the engines in test vehicles to ensure they deliver on reliable horsepower.

“That’s one thing I think separates my methodology from a lot of other aftermarket tuner shops is that we race what we sell,” he says. “We take it to the road course and we beat the crap out of it. We try to break it before we offer it. Every package that we develope is not just something that made this or that on the dyno, it’s been out and it’s been driven normally and in racing situations.”

MTI’s Hemi engine package is 426 cid using either the 6.4L block or the aluminum Dodge Mopar 426 block and the engine is supercharged. The buildfirst starts by disassembling the donor engine and thoroughly cleaning it.

“We have a three-stage cleaning process,” Cox says. “Stuff goes into a dirty room to get washed the first time. It then goes into a prep room to get washed a second time. Then machine work is done on the block or the heads or whatever engine component it is and then it goes back into another two-stage cleaning – a post cleaning, an ultrasonic cleaning and a final rinse. Cleanliness is huge with us here as it is with most of your top engine builders.”

The block then gets sonic checked to make sure that there is sufficient wall thickness. It’ll get bored to the proper bore size, and then MTI will install a crankshaft from either Manley or Callies.

“The connecting rods will also come from Manley or Callies,” he says. “Those are our two main suppliers. For pistons, since we’ve got a heavy background in NASCAR, we have a very strong relationship with Mahle pistons. For almost all of our engine packages, we work with Mahle on a piston design, crown design, ring placement, ring thickness, pin size, pin thickness – all the things that go into a proper piston. We don’t just select a piston out of a catalog.

“We work with COMP Cams on all of our camshafts. We work with both PSI and PAC on our valve spring packages. We work with T&D Machine on our rocker arm assemblies. We always use Mahle Clevite race bearings and we work with Johnson and Howards on our hydraulic lifters.

“We use Edelbrock, Magnuson or Procharger on our supercharger packages. However, all three of our 1,000 horse packages – the LS, LT and the Dodge Hemi – all use the new, larger Edelbrock 2650 TVS Eaton supercharger.

“For valves we use primarily Xceldyne and Del West. On some of the builds we’ll use factory stuff out of the Demon or the Hellcat. We also use ARP fasteners. Our cylinder heads, of course, are CNC ported in-house using select castings. Then, one of the most critical things after that is it goes into what’s called a Newen Epoc machine.

“That machine not only allows you to do an intimate variable of valve job profiles, but it also allows you to blend the CNC operations with the valve job. It’s very accurate, very repeatable, very smooth transitions. That’s one of the biggest problems in the aftermarket when I see people CNC heads. They may do a good valve job and they may do a good CNC, but the transition between the two is actually one of the most critical profiles. I’ve seen more people than not screw that up.”

When it comes to the cylinder head choice, the Hemi heads are based around a production cylinder head as the shop has found those will easily hold 1,000 horsepower.

“Right now, on the Hemi, the 1,000-horsepower package is at the top of the food chain,” Reese says. “I suspect that as we get further into it, it’ll see the same progression that the LS stuff does. As of now, we’ve only been doing the Hemi stuff for a year. We’ll rock along with this 1,000-horsepower package for a while, then somebody will want 1,200 hp and then eventually 1,600 hp and so on.

“What we don’t do are these 2,500 horsepower, blow-up specials. Since my endurance days and Ernie’s NASCAR days, we’ve always tried to focus on and build packages that are reliable. If I can’t build a 1,200 horsepower Hemi that won’t blow up. I won’t build one.”

Instead, MTI Racing builds its Hemis to make a lot of base horsepower, that way, you don’t have to cram a lot of boost in it and rely on that to make the power.

“Our 1,000-horsepower engine packages, without the supercharger, are making 700 hp,” he says. “To get to that 1,000-horsepower mark, we’re achieving that on some builds as low as 17 lbs. of boost, which is not a crazy boost level. That’s the key, I believe, that keeps us reliable is we’re not over boosting the crap out of it.”

The compression on these engines depends on the type of fuel that the customer is going to use, but most regular gas set ups see compression at 9.5:1 versus a drag race set up on race gas, e85 or methanol at 10.5:1 or 11:1.

While Dodge got creative with its Hellcat, Demon and Hellephant engine names, MTI hasn’t named this 426 cid Hemi package, but something tells us that won’t hold this engine back from being a popular option!

Engine of the Week is sponsored by PennGrade Motor Oil and Elring – Das Original.