by David Biello

by David Biello

Imagine a car that could go 300 miles — that’s Chicago to St. Louis — on battery power.

That’s not possible today without either an assist from a gasoline-fueled engine functioning as a charger (the Chevy Volt solution) or an alternate drive provider (the Toyota Prius solution). The fact that such cars need, in effect, two powerplants, means that battery-powered options remain much more expensive than their purely gasoline-fueled peers, which require only a single powertrain.

“We need batteries that last longer, charge quickly and are inexpensive,” says ecologist Joe Fargione of The Nature Conservancy, an expert on the environmental impacts of biofuels, another transportation fuel alternative. “With that, [electrification of cars] would be relatively simple. The rest of the technology is there.”

So the battery the future requires is cheap, more energy-dense and less fragile. No car on the market can meet all of these requirements: the $35,200 all-electric Nissan Leaf has only 100 miles of advertised range, while Tesla’s new souped-up model S, with an advertised 300 miles of range, will be priced at $77,400 and have an actual range that is closer to 240 miles.

Meanwhile, batteries all too often are associated with electrical fires — recall the Sony laptop lithium-ion batteries of several years ago or the recent controversy over the Chevy Volt’s batteries — or they stop functioning because of degraded components. The question is, can such a battery be made?

Batteries have improved immensely in the more than 200 years since scientist Alessandro Volta’s design. Today, carbon and various lithium-based compounds have supplanted the zinc and silver of Volta’s proto-batteries.

Batteries have improved immensely in the more than 200 years since scientist Alessandro Volta’s design. Today, carbon and various lithium-based compounds have supplanted the zinc and silver of Volta’s proto-batteries.

But the same fundamental challenges remain: a battery that stores twice as much energy and can take you twice as far is going to be twice as large, which is to say, too big for a car. And that’s just one of the challenges.

“As a storage device for energy, a battery is notoriously inefficient,” notes Johan de Nysschen, president of Audi of America, though the automaker is investing in battery-powered vehicles. Today’s lithium-ion batteries hold roughly 0.72 megajoules per kilogram. The equivalent amount of gasoline holds 35 times more energy.

Better Battery Health

The search is on for new materials to boost energy storage. One candidate is the same silicon that makes computer chips and photovoltaics possible. This semiconductor can also serve as a powerful anode, as much as 30% more powerful than the carbon anodes used today.

The problem is that silicon doesn’t hold its shape, swelling when charging then shrinking back as it discharges. As a result, much like Volta’s original long ago, batteries employing silicon don’t last very long. Other alternatives to improve on carbon include water and even air — the problem being that volatile lithium can spontaneously combust in both.

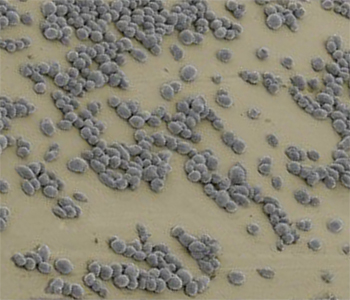

To combat this battery life problem, researchers at Argonne National Laboratory (ANL) and elsewhere are working on devices that could self-heal. The idea is to include microcapsules of liquid metal smaller than a red blood cell along the surface of the anode or cathode. When that surface becomes damaged, the capsules burst and the liquid metal fills in the blemishes cutting off current.

Finally, batteries that could be refilled on the go, such as the “flow batteries” being developed at the Massachusetts Institute of Technology, might provide a solution to long-distance transport, though refueling stops would become more frequent. Think of it as a battery masquerading as a liquid fuel. Essentially, these batteries break up their anode and cathode materials into particles floating in the liquid electrolyte.

Such electricity-generating solutions could then be used until fully discharged, pumped out and the battery refilled with fresh solution, though this poses the usual chemistry and infrastructure challenges facing all battery-powered vehicles. The company Better Place has a similar idea for swapping out more traditional batteries entirely and will begin rolling that system out in Denmark, where installing the infrastructure can be more manageable.

The Era of the Modern Battery

Alessandro Volta built the first modern battery around 1800, by piling discs of zinc and silver separated by cloth soaked in salt water. The salt water oxidized the zinc, freeing up electrons, which then migrated to the silver. By keeping those electrons flowing, Volta induced an electrical current from the battery and was the first to demonstrate the properties of properly configured electrolytes, anodes and cathodes.

This first battery had all kinds of limitations, including almost instant corrosion that would shut down the chemical reactions needed to generate electric current. Plus, Volta’s battery could never be too big because the weight of the discs began to squeeze the salt water out of the intervening cloth.

A Better Use?

In the end, however, even these futuristic batteries and schemes pale in comparison to the energy density and convenience of fossil fuels — a lithium air battery, the most energy-dense battery on offer in the laboratory, might hold roughly one-fifth the energy of a similar amount of gasoline. Further, such batteries will be expensive. “We have solutions to all of our energy problems, but our solutions cost too much,” says physicist William Brinkman, director of the Office of Science at the U.S. Department of Energy (DoE).

But that doesn’t mean that such batteries won’t find a use, for example, in the military, which has partnered with the DoE to test large-scale batteries for microgrids. And renewable sources of electricity, such as the wind and sun, may also rely on large-scale battery storage to smooth out interruptions in the supply of power from such sources.

But it’s cars that really rev the motor of battery enthusiasts. As a result, this year the DoE will launch a new research center devoted to “dramatically improv[ing] battery and energy storage technologies for vehicle and grid applications,” announced Secretary of Energy Steven Chu at an event in Detroit on Jan. 11.

“Imagine a low-cost battery that allows you to drive a few hundred miles, recharge while you stop for lunch, and then drive on for another few hundred miles. Achieving this goal could be transformative.”

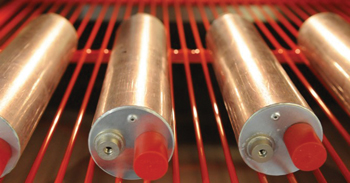

Nevertheless, it is those working on batteries within the DoE who recognize the scale of the challenge — and the hurdles presented by basic physics. ANL developed lighter, safer and cheaper-to-manufacture lithium-ion batteries that also mix in manganese, which will soon be used in the Chevy Volt. But that doesn’t mean the battery will soon triumph.

“Is the battery going to supplant or replace the internal combustion engine?” asked Jeffrey Chamberlain, leader of Argonne’s energy storage initiative, including advanced batteries, at a New America Foundation event this past October on energy in 2030. “That’s never going to happen: not in my lifetime, my children’s lifetime or my children’s children’s lifetime.”

David Biello is an associate editor at Scientific American. In December, he won a Silver Baton 2012 Alfred I. duPont-Columbia University award for hosting and co-writing the Detroit Public Television special “Beyond the Light Switch.” He has written for publications ranging from Good to Yale e360 and speaks on radio shows such as WNYC’s “The Takeaway.”

Article provided courtesy of www.txchnologist.com.