For some time now, most of the development in diesel technology has been aimed toward making the engines environmentally friendly. But as diesel engines have become cleaner, the power levels have also increased. This is somewhat backward to what the country went through in the 1970s with gasoline engines.

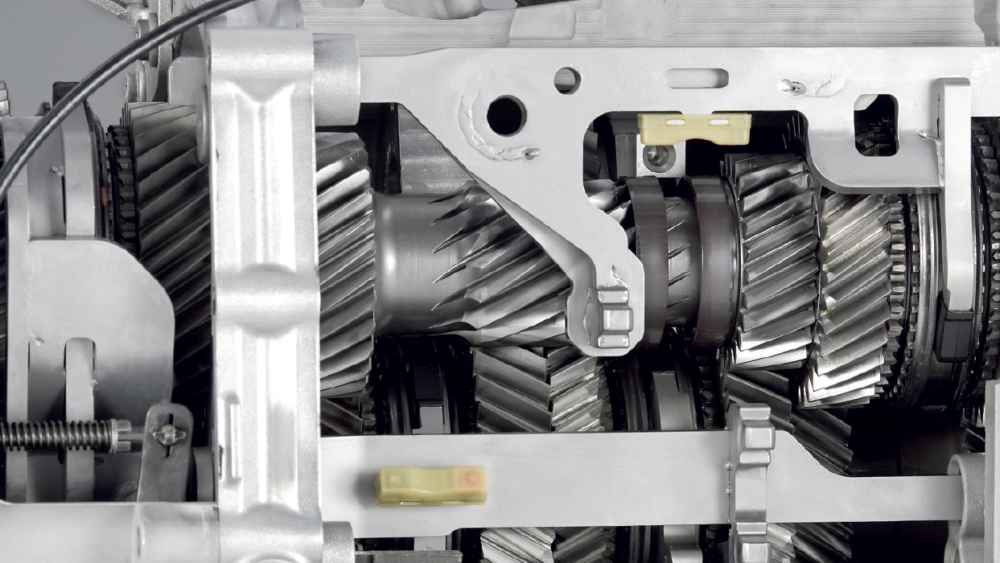

BMW Dual-Clutch Transmission Diagnostics

A DCT transmission uses the gearing principles of a manual transmission.

The phrase “dual-clutch transmission” or DCT can strike terror in the heart of some BMW engineers and technicians. You will probably never deal with the internals of a DCT transmission like the gears, synchronizers and shafts. You will instead have to repair the external components that control the clutches and cool the fluid. But, understanding how the gears and shafts work together is essential.

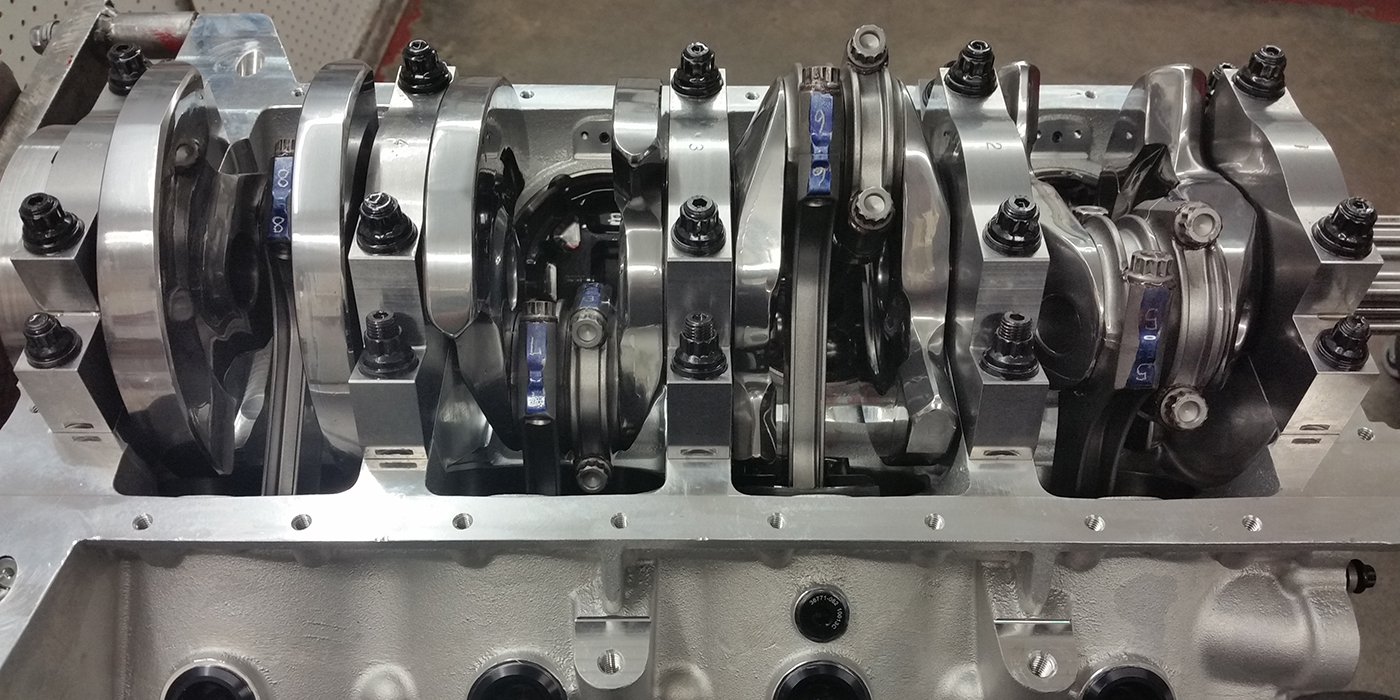

Simple Engine Fasteners Actually Complex Engineering Systems

Fasteners act much the same as a spring due to the physics of stretch and rebound.

Superchargers: Pros And Cons

Customers generally look to superchargers for the instant throttle response, not fuel economy.

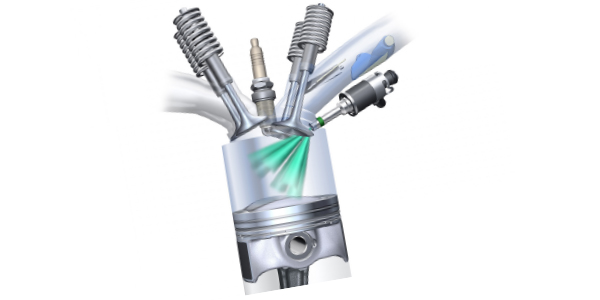

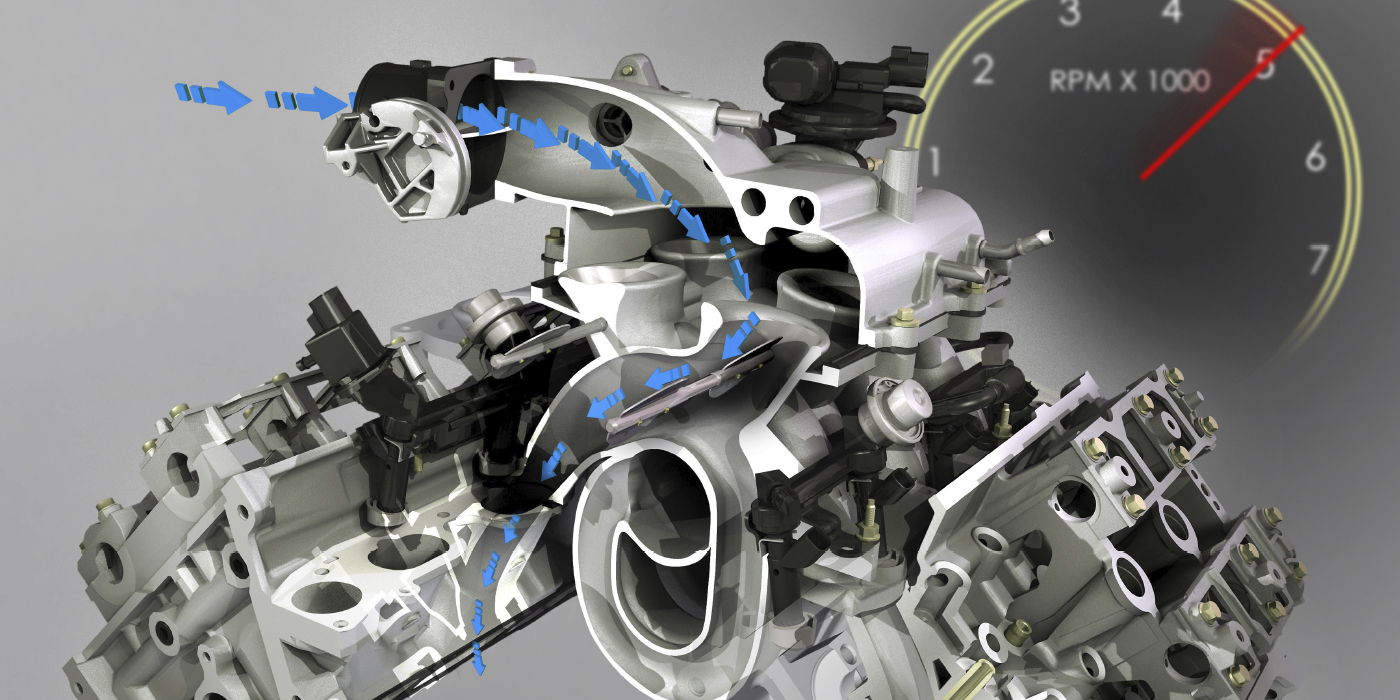

Runners And Ports: How Modern Engines Manage Air

Variable-length intake runners change the length of the intake passages depending on engine speed and load.

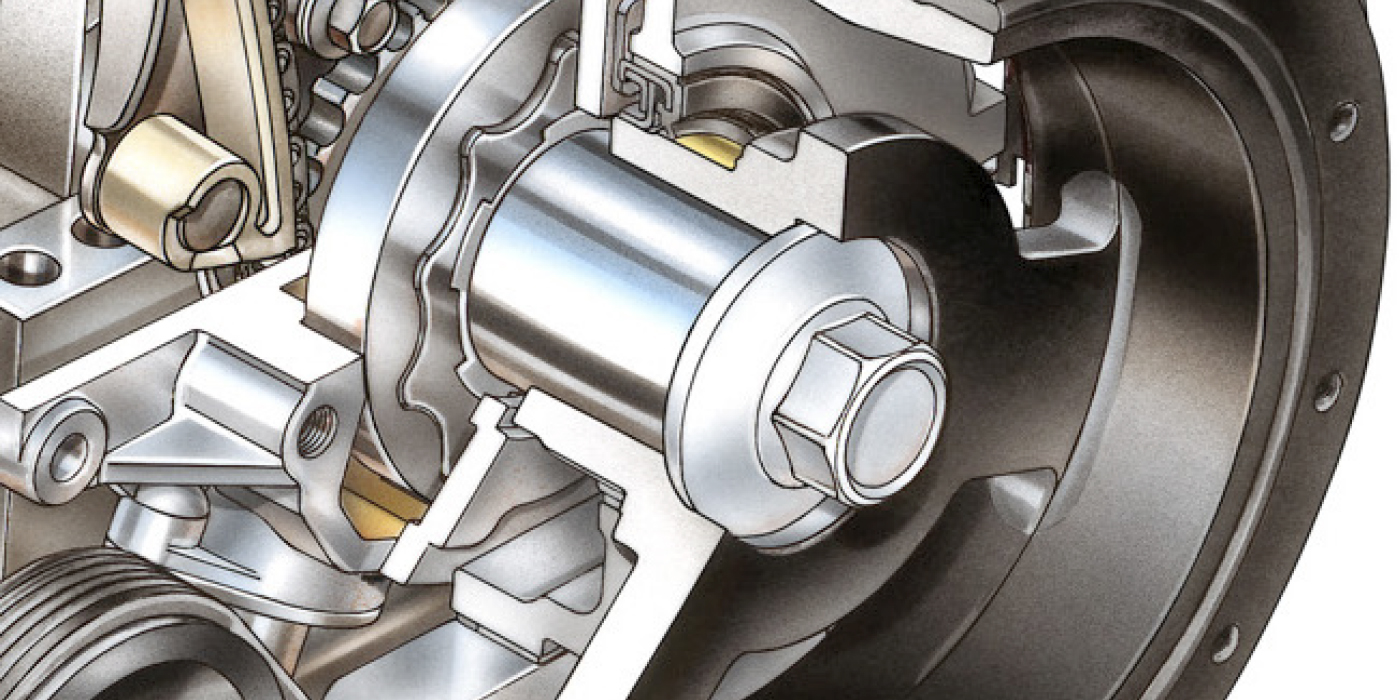

Driveshaft Universal Joint Tips And Techniques

Before removing the driveshaft, check for play in the yoke and slip joint. If the u-joints are failing, you should be able to see movement in the shaft as you apply leverage.

Other Posts

Diesel Air Filter Replacement

Here are some diesel air filter replacement tips in order to keep these vehicles running as intended.

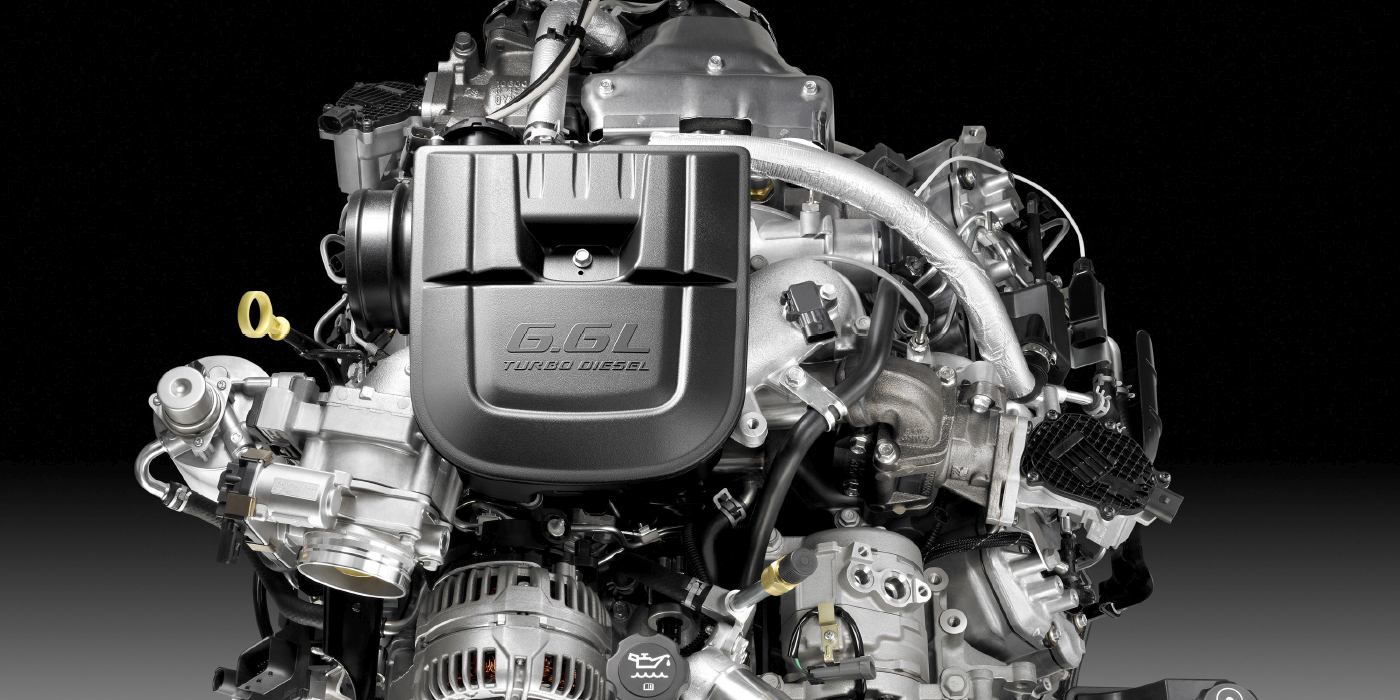

Duramax 6.6L Turbocharger Replacement

No matter the symptoms or damaged parts, the root cause of the failure must be diagnosed and resolved.

Dodge®/Ram® Cummins® Turbo Diesel Engine Repair Solutions

Known for their versatility and toughness, diesel engines are the first choice for many truck owners—and among those engines, Dodge®/Ram® Cummins® turbo diesels consistently rise to the top of the pack. Since 5.9L engines produced between 1991 and 2010 provide reliability you can count on, don’t trust their repairs to anything less than top-quality service

Diesel Exhaust Fluid Innovation

Almost all vehicles built since 2010 are equipped with Selective Catalytic Reduction (SCR) and require diesel exhaust fluid.