In March, the U.S. Environmental Protection Agency announced it reached settlements with three Northwest resellers and manufacturers of aftermarket parts specializing in diesel pickup trucks. Alligator Diesel Performance, Diesel Power Products, and Deviant Race Parts were alleged to have violated the Clean Air Act by selling aftermarket products that defeat the emissions control systems of diesel engines.

The EPA maintains that diesel engines emit large amounts of nitrogen oxides and particulate matter, both of which contribute to serious public health problems in the U.S. These problems include premature mortality, aggravation of respiratory and cardiovascular disease, aggravation of existing asthma, acute respiratory symptoms, chronic bronchitis, and decreased lung function. Numerous studies also link diesel exhaust to increased incidence of lung cancer.

The EPA estimates that the defeat devices that were installed from a single year of product sales by the companies resulted in an estimated 49 million pounds more air pollution than would have otherwise been emitted. The companies agreed to stop the manufacture and sale of all products the government alleges violate the CAA as part of the settlement. Furthermore, the companies agreed to pay penalties of $180,800. The penalty for each company is reduced due to their financial ability to pay a higher penalty and stay in business, according to an EPA statement.

“These companies manufactured and sold tens of thousands of aftermarket defeat devices, and as a result, tens of thousands of heavy-duty trucks now operate without the filters, catalysts and other emissions controls that help keep our air clean,” said Chris Hladick, Regional Administrator for EPA’s Region 10 office in Seattle. “These settlements will prevent future violations by requiring the companies to ensure that their products do not adversely affect emissions.”

There have been other high-profile fines for diesel shops recently, including the stars of the TV show Diesel Brothers being ordered to pay $851,451 for their role in producing and selling modified diesel pickups in the state of Utah. While many shops may think this is all political, the current administration tends to side with industry over the environment, yet cases are pending and going forward. The point is: if you’re working on any diesel engines to increase the performance of an on-road (street) engine, you need to know what you can and cannot do so you don’t get a G-man knocking on your door.

According to Rich Strube of Richies Diesel Performance in Hicksville, NY, the CAA is a necessary and justifiable cause. “But I believe they are approaching the ‘territory’ a bit too aggressively. Emissions laws are necessary within reason, and it’s my belief we can regard these regulations both with and without the after-treatment systems in place. Theoretically, when the task of creating a clean-running diesel is taken on intelligently and appropriately, the goal can be accomplished with positive results.” Meaning, Strube believes that you can make both sides happy instead of being fined. Many builders think there’s a way to make power and meet the standards, but the EPA only sees one way to do it.

How We Got Here

In the 1960s, the American public began getting concerned about pollution. Several environmental disasters had raised awareness, including when the Cuyahoga River in Cleveland, caught on fire due to being polluted with chemicals from nearby factories. There was also a massive oil spill off the coast of California that lead to President Richard Nixon to present Congress with a plan to organize resources and keep such disasters from happening. Smog in major cities was also beginning to get noticed as astronauts photographed the Earth from space.

The EPA was formed in December 1970, and by 1974 it essentially went to war with the automotive industry to clean up tailpipe emissions for 1975 model year cars. The source of gasoline was switched from leaded fuel to unleaded, and catalytic converters as well as “smog pumps” were introduced on gas-powered vehicles, along with a variety of other safety measures. But heavy-duty diesel-powered pickup truck engines were mostly left alone until 2006 when our diesel fuel supply switched to ultra-low sulfur diesel.

Diesel exhaust contains known carcinogens like benzene in addition to gases that are probable carcinogens (e.g., formaldehyde, 1,3-butadiene). Exposure to diesel exhaust may also cause problems with the respiratory system if chronically exposed. Smog can form at the ground-level ozone layer due to reactions between nitrogen oxides (NOx) and volatile organic compounds (VOC). This is not to be confused with the stratospheric ozone layer, which protects Earth from objects and gases in space from entering our atmosphere. Vehicles contribute about half of the NOx that is emitted, according to the EPA.

For those who want serious diesel power, stick with pulling or drag racing since emissions are not an issue for off-road race applications due to their limited use.

Doug Anderson, an Engine Builder contribor, who is now retired from Grooms Engines and “living the dream” outside of Nashville, TN, told us that he continues to keep up with the industry he’s loved since he was a teenager. He said the problem with diesel and the EPA go back to 2007-‘08 when he was working at Grooms. “The primary problem is that the EPA had to control nitrous oxides on diesel engines differently than automotive gas engines. We’ve known about it since the ‘70s, and the whole idea is that you cannot control nitrous oxide through a catalytic converter or any other way. The only way you can control NOx is by not letting it form oxides (O2), which means you don’t have as much oxygen present. You can’t get it too hot, so to do that, we take inert gas, and we recycle it in the engine.

“With a diesel engine, the combustion temperature is much hotter. So the first thing we had to do when [the EPA] said you’ve got to get rid of the nitrous oxide was we had to cool it. We ran an EGR cooler, but over time, on the Ford, in particular, the 6.0L Powerstroke EGR cooler would get plugged up with soot. When the EGR got plugged, the oil got too hot and would then plug up the oil cooler. And so you could figure by 100,000 miles you are going to need new head gaskets.”

Ron Knock, the owner of DIESEL Motorsports, which puts on diesel drag racing events across the country, says that when they started almost 14 years ago, a truck with 600 to 700 horsepower was one of the top-level trucks. “One of the top pulling trucks back then was 700-800 hp. It was a street truck, too, an everyday driver!”

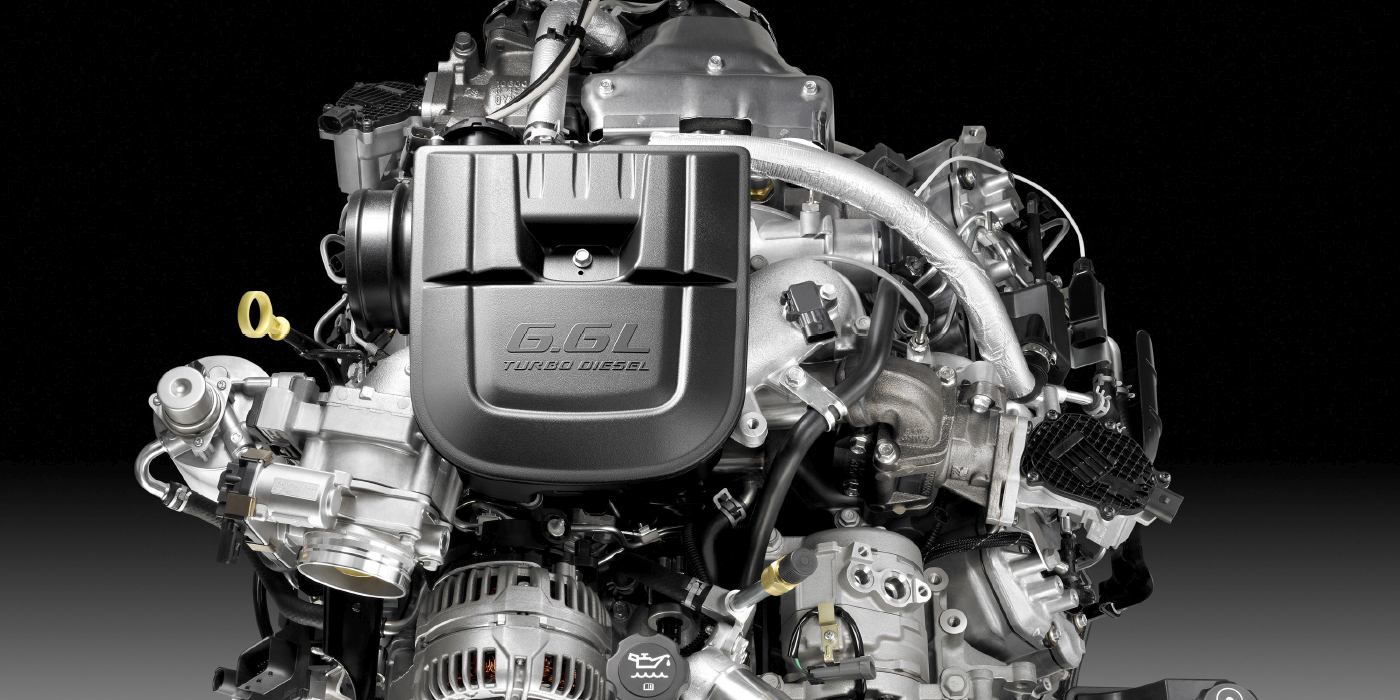

Today, he says diesel trucks are 450 hp from the factory. “Back in the day when the stock trucks were only 150 hp, they still had 450-ft.-lbs. of torque. They just didn’t have any horsepower. Now they come off the line at 450 hp and 900 to 1,200 ft.-lbs. of torque – so it’s changed considerably. And that’s with all the EPA stuff onboard (i.e., EGR, DPF, SCR, DEF, etc.).”

Before the EPA started snooping around, Knock says there were relatively few restrictions on diesels. “I mean they had mufflers and kind of a catalytic converter or a catalytic converter pipe, which was nothing more than a hollow tube. It was more like a restrictor than it was a catalytic converter.”

After 2008, the OEMs were mandated to use a diesel particulate filter (DPF). Knock says at that point the EPA didn’t bother the diesel aftermarket as many shops and enthusiasts were cutting them off. “Diesel shops made a huge amount of money with ‘delete kits’ up to about 2012. And that was because some kids and a few people online attracted a lot of attention doing crazy stuff like ‘rolling coal’ all over the place. The ‘Diesel Brothers’ supposedly duct-taped a guy to a chair and pointed the exhaust at him. He was covered in soot.”

Knock acknowledges the popularity of shows like Diesel Brothers and Youtube videos, but he says none of the diesel shops he works with looks (or acts) like that. “They wouldn’t be a business very long if they did. It is for sensationalism. It’s like guys think everybody in Alabama looks like ‘Duck Dynasty’, you know? It’s on TV. No one is like that. I’ve had calls from Youtube shows wanting me to endorse them, but I say, ‘I can’t guys, you’re blowing smoke!”

Knock says, whatever side you’re on, the Youtube culture only promulgates what we can’t have on the streets. “The EPA is against it, and all [Youtube] did was escalate it for the EPA.” While many diesel enthusiasts are racers and build their vehicles for pulling or other off-road uses, DIESEL Motorsports drag racing is primarily for street-driven trucks. Competitors show up at events with vehicles that they drove to the track, so all of the emissions equipment has to be functional. While there’s a substantial market for late-‘90s to early 2000s-model diesel trucks because they don’t have as many restrictions, engine builders are finding good power with relatively stock builds by adding a few essential modifications.

One of the keys to bringing diesel technology into the 21st century has been electronic engine controls. Replacing mechanical injection pumps and injectors with a high-pressure common rail injection system allows late-model diesels to deliver better fuel economy, cleaner emissions and more power from the same number of cubic inches.

“But with great power, comes great responsibility,” as the Spiderman principle cautions. With electronic controls, you can bump up the boost with an aftermarket tuner tool. And since the engines are overbuilt anyway, there’s plenty of room to dial them up. But these tuner tools are mostly obsolete for significant horsepower gains on street engines. Late-model diesel engines are designed to leave a trace if the ECU has been hacked. This will void any warranty the owner may have. Piggy-back ECUs, however, can be used since they add or subtract from the stock map, but we don’t condone it for the street.

Instead, most diesel builders are looking for ways to make power without butting up against the CAA. Can it be done? “Absolutely and undeniably,” says Strube. “Granted, the power output may not be what every enthusiast is after, but the ability to make clean, responsive power without any smoke is possible without question.”

Everyone has varying positions on the emissions equipment and the engine’s actual dependency as it correlates to providing the desired emissions output. The technology is there. However, the EPA has instilled fear in the eyes of the industry, and I think tuners/builders are reluctant to cross that threshold.

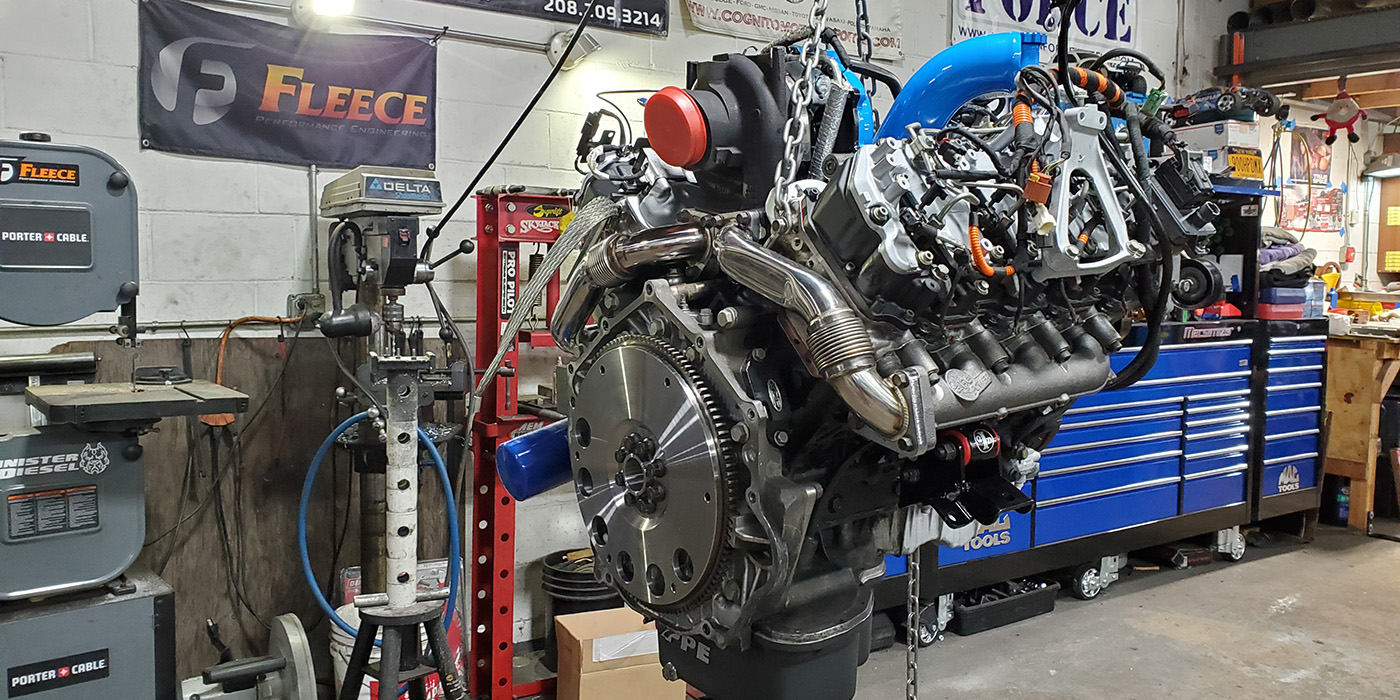

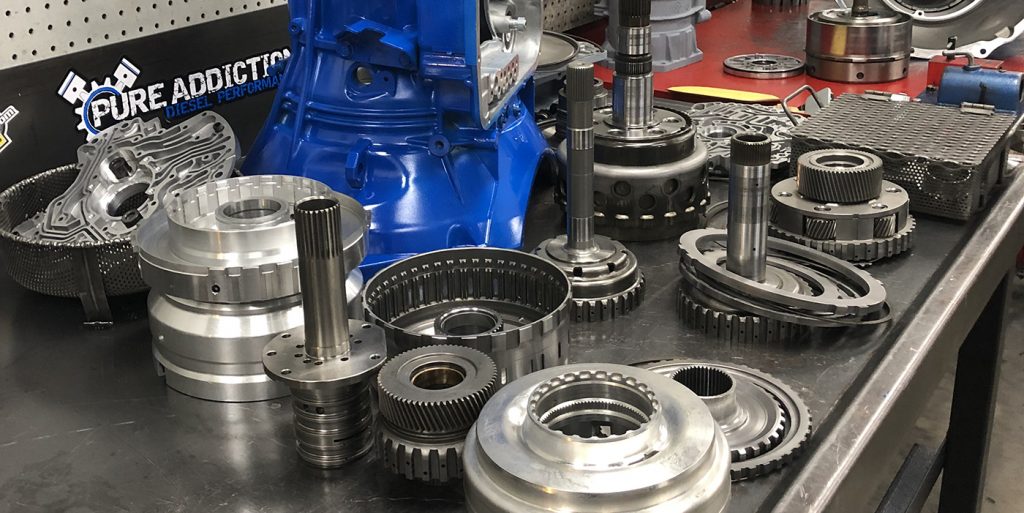

In the past, many diesel tuners used defeat devices to produce power without cracking the engine open. Today, performance is gained more from upgrading internal components and injector technology. “I believe the reason for this is; we were never forced to look beyond the tuning,” says Strube. “We relied on the technology given by the manufactures as equipped with each platform, and hardware exchanges were not made until the next tier of power was created.”

According to Strube, it was simple to download a tune, bolt-on an exhaust, and away you went. Now, large companies have delved into the internal components like injectors, turbos, and manifolds, etc., looking for ways to more efficiently make power with the foundations already set in place. Simple changes to airflow velocity and fuel atomization in the combustion area can yield lower opacity levels through a much cleaner burn. The industry is now left with no alternative other than working with what exists and making the most, cleanest power possible.”

Exhaust Gas Recirculation (EGR) has been a dirty word with diesel enthusiasts because it can reduce power. EGR reroutes some exhaust gas back into the intake manifold to lower combustion temperatures when the engine is under load and is needed because diesels produce a lot of NOx compared to gasoline engines. But it also raises intake valve temperatures and can cause carbon deposits in the intake manifold, valve ports and intake valves, which will likely cause other failures.

While some enthusiasts continue to make illegal modifications to their diesel engines, the benefits may not be worth the risks as they may only see a little extra power at the rear wheels and a few more miles per gallon. For those who want serious diesel power, stick with pulling or drag racing since emissions are not an issue for off-road race applications due to their limited use.

“Everyone has varying positions on the emissions equipment and the engine’s actual dependency as it correlates to providing the desired emissions output,” says Strube. “I have worked on ‘non-equipped’ platforms where the opacity levels were so low, nearly zero deposits were found on the tailpipe. The technology is there. However, the EPA has instilled fear in the eyes of the industry, and I think tuners/builders are reluctant to cross that threshold now.”

This article is courtesy of Engine Builder.