The variable “valve” timing that most of us see in our shops is actually variable “camshaft” timing that improves low- and high-speed torque by advancing or retarding the camshaft timing on single overhead camshaft (SOHC) engine applications.

In contrast, some double-overhead camshaft (DOHC) applications perform those same functions by separately advancing or retarding the intake and exhaust camshafts.

Fully variable valve timing can be achieved only by using computer-operated solenoids to precisely control the intake and exhaust valve opening and closing events. Although the various combinations of valve timing events are theoretically infinite on an electronically controlled system, their applications are limited due to issues of cost and, in some cases, reliability.

VVT Hardware

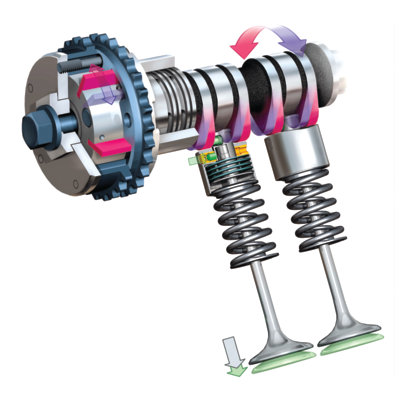

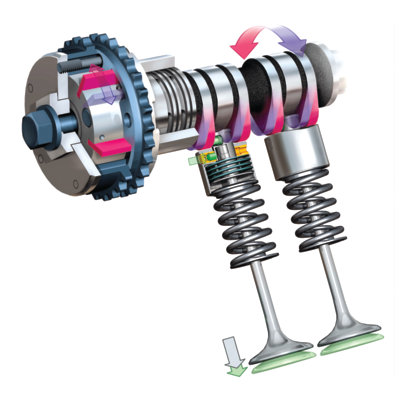

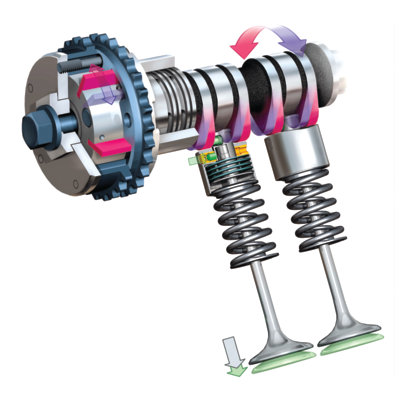

Variable camshaft timing on early SOHC engines was achieved by using a camshaft “phaser,” which consisted of a spring-loaded hydraulic piston that forced a beveled drive gear against a similar beveled drive gear mounted on the camshaft.

Precise camshaft timing can be achieved by using the Powertrain Control Module (PCM) to apply oil pressure to the piston by pulsing an oil control valve. Since the piston has an orifice to bleed away oil pressure, cam timing can be changed by increasing the pulse width applied to the oil control valve.

If the electronics fail, a phaser return spring will push the piston to its default timing position.

Diagnostic Tips

As you might have already guessed, VVT diagnostics are very application-specific. VVT diagnostics not only depend on whether the engine is an in-line or V-type block, or an SOHC or DOHC configuration, but also the configuration of the phaser and system electronics. In addition, there are dozens of “global” P0010- and P0340-series trouble codes, not to mention manufacturer-specific P1000-series codes that can be stored due to a valve-timing problem. But by applying basic operating principles, it’s possible to diagnose most VVT failures, regardless of configuration.

Most VVT failures will result in a loss of low- or high-speed engine torque and affect intake manifold vacuum. When the camshaft is not responding to the positions commanded by the PCM, the PCM should store a camshaft-related timing P0340-series error code. On V-block engines, a camshaft timing error on one bank might also result in P0300-series misfire codes for all cylinders on that bank.

Remember that valve timing and valve overlap affect cylinder compression. With a single-bank failure on a V-block engine, the bank-to-bank cranking compression should differ, as should the bank-to-bank fuel trim numbers. Keep in mind that with the re-introduction of steel timing chains, a single loose chain or a worn tensioner or chain guide on one bank can retard cam timing and perhaps affect cold starting and driveability performance.

Engine oil viscosity as well as oil filter flow capacity can definitely affect the ability of the cam phaser to control valve timing, as can the service life ratings of the oil.

A non-OE approved oil, coupled with a low-capacity oil filter, can cause sludging or varnishing, which causes cam phasers to stick in advanced or retarded positions. This may also cause the oil passages in the cylinder head, oil control valve and phasers to clog with sludge or become contaminated with metal chips. Even when using OE or OE-approved oils, engine oil must be changed at recommended intervals.

Many advanced diagnostic technicians routinely collect labscope samples of CMP and CKP sensor waveforms known to be good for future comparison with those produced by similar models afflicted with suspected valve-timing problems — but that’s a story unto itself.

In the meantime, it’s a good idea to check each VVT vehicle for scan tool-based cam timing data.