The Delphi Technologies Difference.

We start with the OE design and conduct extensive dimensional and material analysis to develop our part that will perform reliably on any vehicle. We’re passionate about our stringent technical standards—it’s in our DNA.

Integrated OE expertise

- Delphi Technologies applies its 80+ years of OE expertise and pioneering technology to every fuel pump and module in our aftermarket portfolio. We own more than 30 OE-proprietary innovations and 150 patents.

Leading vehicle coverage

- As a leading Tier 1 supplier to the top 25 global vehicle manufacturers, Delphi Technologies covers 99% of fuel handling applications in North America.

Expert technical support

- As a leader in fuel technology, Delphi Technologies provides expert-led training programs (100+ years combined trainer experience) and a tech hotline to ASE Master Technicians and OEM experts.

Fuel technology you can rely on

- Anodized aluminum can reduce flow loss by up to 100% in severe contamination.

- New carbon commutator extends pump life by up to 300% over commonly used copper, by reducing oxidation and premature wear in contaminated fuel or fuel with alcohol blends.

- Over-molded armature protects pump windings in corrosive environments.

- Button style contacts feature additional wear material that can last for over 1 million cycles.

- High capacity synthetic mesh is able to filter out all items larger than 30 microns.

- Distinctly Delphi with electric blue fuel pump top, module top cover and strainer material.

Ask for fuel system products from Delphi Technologies.

Tech Tip

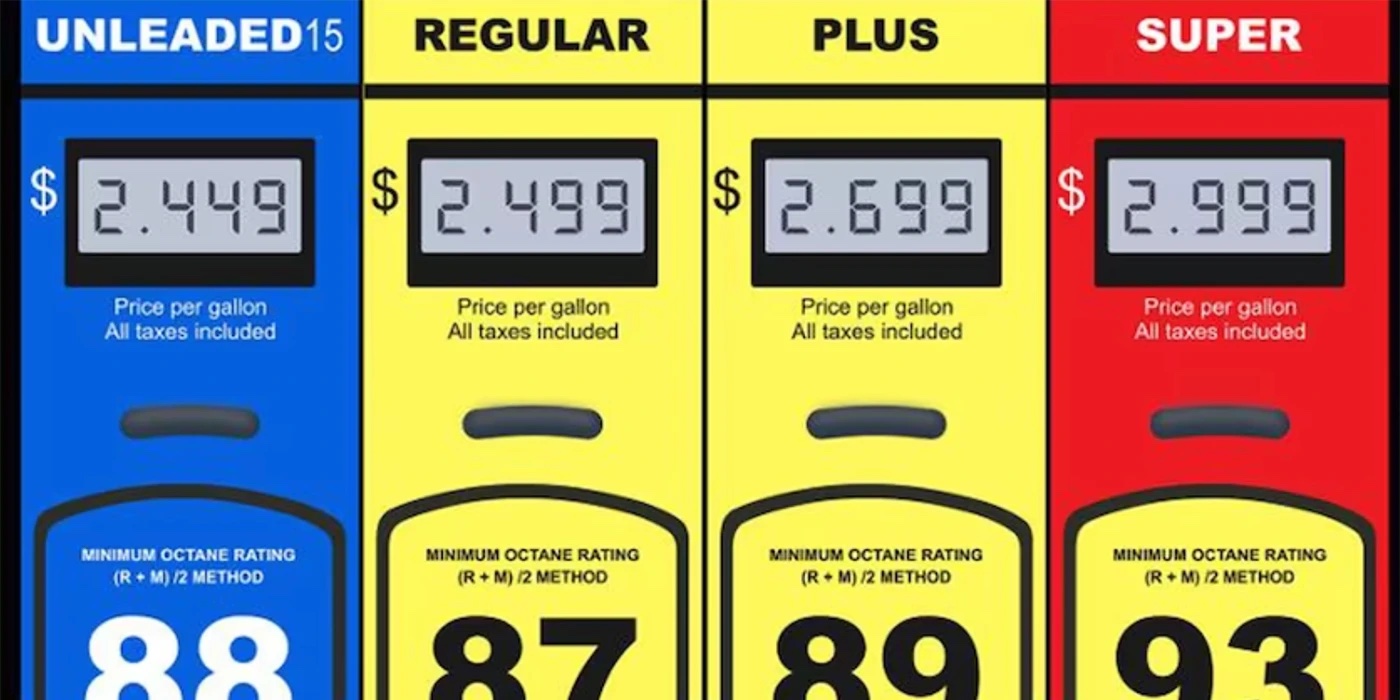

Before installing a new fuel pump, it is critical to properly clean your fuel tank. Debris and contamination from your aging fuel tank can clog the fuel pump strainer, causing premature wear and tear, and in extreme cases, can break your new fuel pump. The time it takes to clean out the debris (about an hour) is nothing compared to the time it takes to redo the entire job.

Likewise, reusing the same, old fuel in a recently cleaned fuel tank will bring back debris and contamination that likely damaged the previously replaced fuel pump. Save yourself time, hassle, and money by doing the job right the first time- Clean the fuel tank before installing a new fuel pump and refill the fuel tank with fresh fuel.

For your convenience, Delphi Technologies offers a Fuel Tank Cleaning Kit (FC01) that includes a low-suds cleaning solution specifically designed to easily treat and rinse up to a 40-gallon capacity fuel tank.

Check out our short How-to video.

Visit our online catalog or ask your Delphi Technologies sales representative for more information.

This article was sponsored by Delphi Technologies. For more information, please visit https://www.delphiautoparts.com/usa/en-US.