Deloitte’s has released its sixth Automotive Supplier Study.

The study examines the impacts on the supplier landscape as it braces for the potential of continued disruption and fundamental change on the horizon.

Additionally, the study is based on a quantitative analysis of financial performance from nearly 300 global automotive suppliers to study how electrification adoption could impact supplier components.

Key takeaways from Deloitte’s Automotive Supplier Study

- Automotive component segments tied to electric vehicles (EVs) continue a strong upward trajectory, with total revenue for electric drivetrains and battery and fuel cells segments expected to potentially increase 245% from 2022 to 2027.

- Amid the impact of multiple obstacles over the past three years and the compounding effect of an inflationary environment, some automotive suppliers will be unable to continue to invest and grow and may lead to greater industry consolidation.

- Strong government incentives aim to reduce dependence on globally integrated supply chain structure and could force a rethink of existing supplier relationships and material sourcing strategies.

Why it matters

Automotive manufacturers and suppliers generally continue to realign their strategies to meet changing economic, geopolitical and industrial headwinds around EV adoption, increasing capital costs, unstable raw material sourcing and declining revenue projections tied to legacy cluster components.

Automakers aim to reduce complexity amid capital concerns

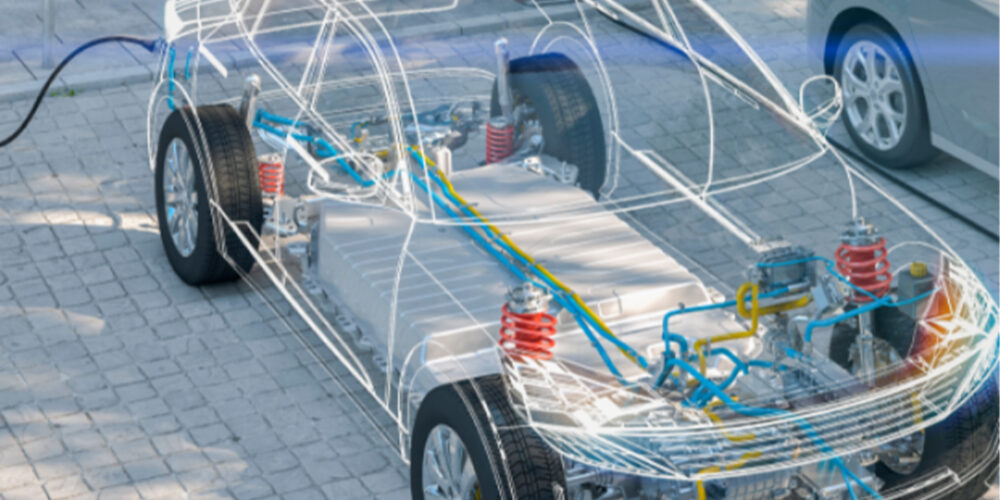

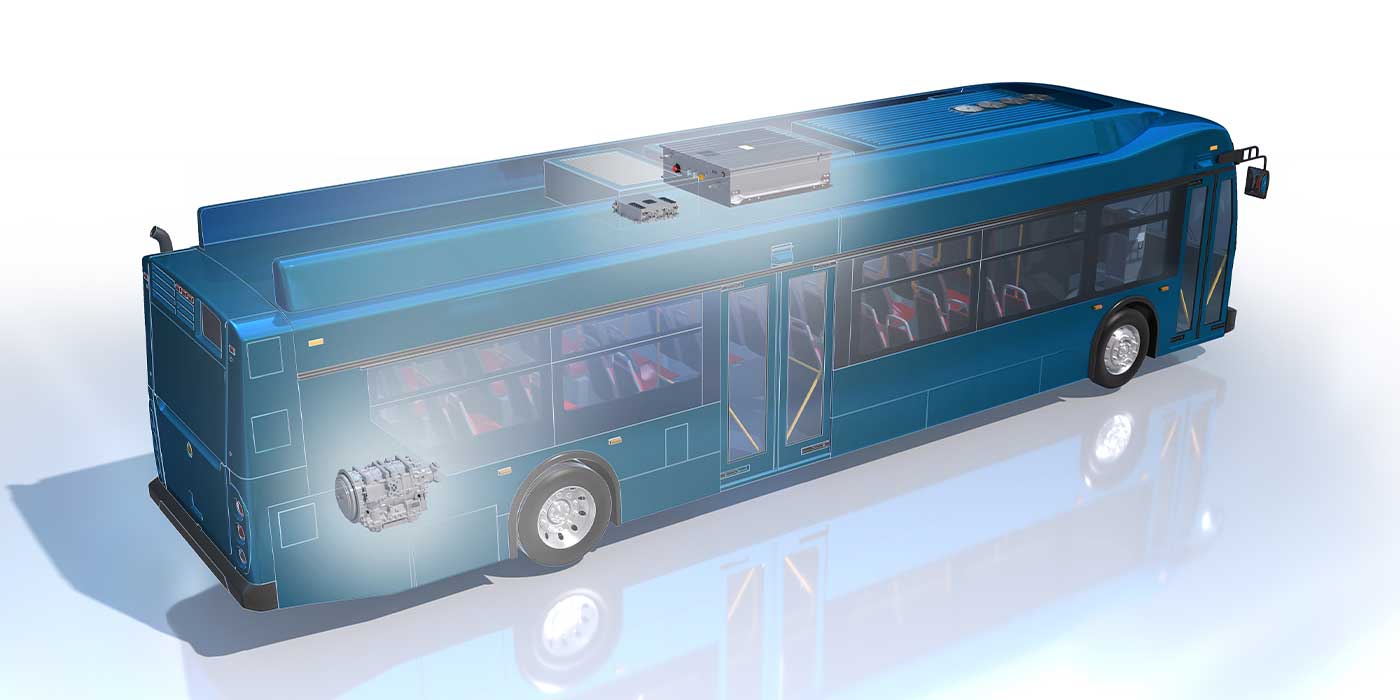

As some automakers focus on EV-driven production models, this shift towards more standardized, less complicated vehicle architectures may lead to fewer, more competitive opportunities for suppliers to engage with OEM customers. This may create significant friction among existing suppliers trying to keep up with these fundamental changes as automakers find themselves either “all in” regarding electrification, versus those looking to maintain a foothold in the legacy internal combustion engine (ICE) world.

As a result of the semiconductor shortage, some automakers used cratered inventories to their advantage via increased pricing and profitability. This was, and currently still is, a stark contrast to the supplier landscape, where low-volume environments were exacerbated by production planning instability and expedited freight. The resulting debt, matched by rapid increases in interest rates, means suppliers may face a confluence of capital challenges that could increase the risk of additional supplier bankruptcies over time. However, in an effort to close the significant capacity gap in mining and refining battery minerals for EVs, governments introduced new financial incentives for battery manufacturers to establish production lines in the U.S., creating new opportunities for suppliers across the value chain.

EV component growth continues while traditional structures wane

As the industry continues to invest in zero-emission vehicles (i.e., battery-electric vehicles and fuel-cell vehicles), demand for supplier components will likely splinter into a series of divergent paths. Despite interest in new mobility and rising software-defined experiences, legacy clusters tied to “traditional” ICE vehicles will likely remain a viable market for the foreseeable future regardless of stagnant or declining growth.

- Both electric drivetrains and battery/fuel cell segments are poised for possible exponential growth: each is projected to potentially increase 245% between 2022 and 2027, with a combined market size of $200 billion at the end of the forecast window. Additional segments positioned for potential growth include advanced driver assistance systems (ADAS)/sensors (up 75%), followed by interiors (up 39%) and electronics (up 37%).

- Market segments generally expected to remain stagnant or grow at the same rate as volume of vehicles sold in the next five years include chassis/frame ($147 billion) and seats ($76 billion).

- Despite ICE parts showing a 44% decline from 2022 to 2027, the projected $70 billion market should remain relevant as consumer demand continues to align with traditional ICE vehicles at 62%, according to Deloitte’s recent Global Automotive Consumer Study.

“Adapting to new mobility structures and electric vehicles in and of itself can be an enormous challenge for the automotive sector. When combined with sustained material volatility, shifting consumer demand, hyperinflationary economic environments and rising geo-political considerations, to name a few, you start to realize how resilient the global automotive industry seems to have been these past few years,” said Raj Iyer, managing director, Deloitte Consulting LLP. “As many auto manufacturers look to use the transition to EVs as a catalyst to reimagine their manufacturing footprint, suppliers may be faced with hard decisions to determine where on the future value chain they are most likely to grow or, in some cases, survive.”

Government incentives spur supplier rethink on near-shoring supply chains

In response to rising levels of socio-political uncertainty, suppliers may be met with considerable encouragement by regional governments to bolster resiliency and local relationships. Combined with the rapid development of EV technologies, suppliers should think about what they produce and how they produce it, along with what relationships will have to be augmented or perhaps reforged entirely to take advantage of available tax credits.

As seen with the semiconductor shortage, a greater need has been placed on developing and implementing proactive sensing capabilities. This degree of insight and planning will be critical to help develop alternative strategies regarding commodity procurement in the event of trade bans and regarding the traceability of key minerals to provide assurance on sustainable methods and calculating carbon footprints.

Applying a strategic framework to focus on sector opportunities

To help position themselves for success amid increasingly difficult terrain, suppliers should explore strategic options based on the growth trajectory of component categories. Depending on a supplier’s current positioning in each category, suppliers can either expand, defend or pivot their business using specific tactics. For instance, suppliers in growth segments can potentially expand their business by utilizing non-traditional financing, while others can help defend their position by forming strategic alliances.

Suppliers should make careful decisions to help align their business to these new sector realities and emerging areas. New channels for strategic integration, especially among burgeoning e-mobility sectors that have been overly exposed to financial pressures, may allow more prominent players to bolster innovation efforts via acquisition. The potential for more M&A activity including joint ventures and partnerships remains great as strategic and financial buyers could look to take advantage of the current conditions.

“As we’ve seen with the semiconductor shortage, some automakers are going to considerable lengths to establish relationships with suppliers further upstream to offset potential future obstacles and achieve greater visibility across the supply chain,” said Jason Coffman, U.S. automotive consulting leader and principal, Deloitte Consulting LLP. “Additionally, to help bring down costs, some OEMs are focusing new efforts on engineering the complexity out of vehicles to improve margins and non-value-added supply chain costs. This can place further pressure on suppliers to compete for access to new programs or instead pursue strategic divestitures and or acquisitions to help improve their global competitiveness.”

Download a copy of the report here.