Ford Tech Tip: No Communication Codes

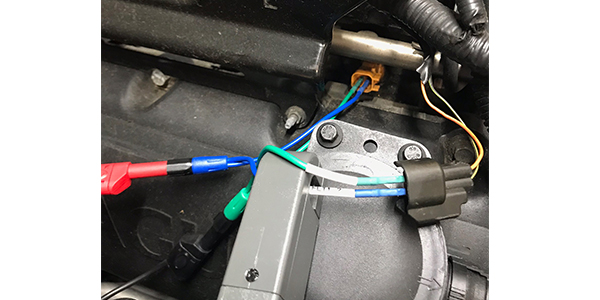

When addressing a module “No Communication” related issue, it is important to perform a visual inspection of the vehicle in various locations. This will help identify potential tampering, modifications or the presence of aftermarket electronic add-ons.

Embracing ADAS!

Are you afraid of Advanced Driver Assistance Systems (ADAS)? A hot topic at recent training events and online forums, much of the hysteria regarding ADAS is driven by news stories about new vehicles that are able to drive on freeways on their own, or a horror story about a Tesla crashing into something on the highway. But, the current reality of ADAS at the shop level is quite different.

Don’t Fear The Turbo

The turbocharger gets a bad rap. So many technicians can name reasons why they have failed in the past, yet they can’t recall when or why a turbocharger has failed recently. With more and more vehicles employing a turbocharger to achieve power and fuel efficiency from a downsized engine, the importance of maintenance is more critical than ever.

Secondary Air Injection Tips

Secondary air injection can be supplied actively from an electric air pump or passively from pulse pressure in the exhaust system. In a passive/pulse system, air is drawn in when a valve opens from vacuum created through exhaust flow. In an active system, air is blown from an electric pump, which allows for better control.

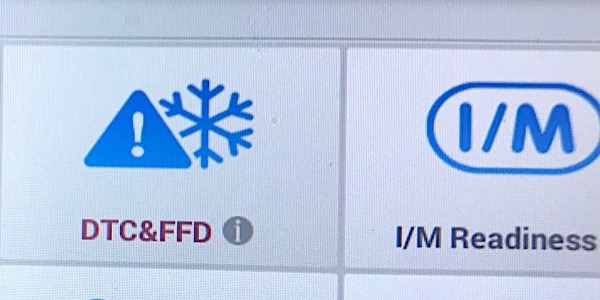

Scan Tool Freeze Frames: Using Generic Data To Make A Specific Diagnosis.

As part of OBDII, Mode$02 for the logging or freeze frame data was created. This diagnostic protocol saves data PIDs and information when a code is set. In 1995, freeze frame gave technicians a powerful diagnostic tool that was previously only available on expensive factory tools.

SAE J2534, Part II: How Much Money Are You Losing By Not Doing Vehicle Reflashing?

In Part I of this series, I talked about what J2534 was and a bit about how it works. I would like to use this followup article to lower the fear factor and tell you what to expect when setting up a computer to run a J2534-supported software program.

Replacement Auto Part Standards And Regulations

With the recent tariffs going into effect, it has sparked the discussion about regulations for vehicle replacement parts to keep some imported auto parts off the market. Most people think that with a stroke of a pen dangerous and sub-standard parts could be banned and parts quality will be improved overnight. But, what standards should be applied? Who should do the testing? This is where things get tricky.

Using Fuel And Ignition Waveforms Together

Fuel injector and secondary ignition waveforms can show the condition of the fuel and ignition system, and combined they can give you new insights on misfires and if they are related to the fuel or ignition system. Scan tools can tell you if there is a misfire and which cylinder is misfiring. Rarely will you be able to determine if it is the ignition coil and spark plug or if the fuel injector is causing a rich or lean condition. With a scope that has the correct probes, it is possible.

Understanding Oil Additives: New Engines, New Standards

Have you noticed that it is getting harder to stock oil these days? For some vehicles, the same model may take three different types of oils, depending on the make or engine. The base model may require a 5W-30, while the V6 version may require a 5W-20, and the hybrid version may require a 0W-20.

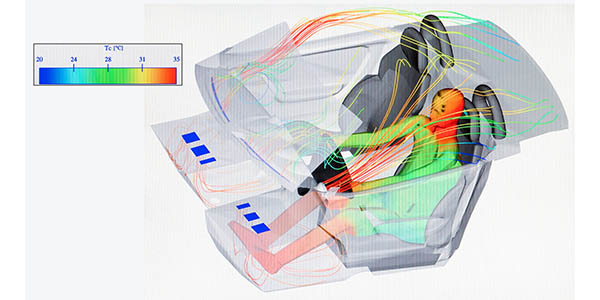

HVAC Sensors: More Than Just Temperature

When a driver sets a temperature in the control head of an HVAC system, what does it mean to the vehicle? Seventy-two degrees could mean many different settings depending on the outside temperature, humidity and even the position of the sun.

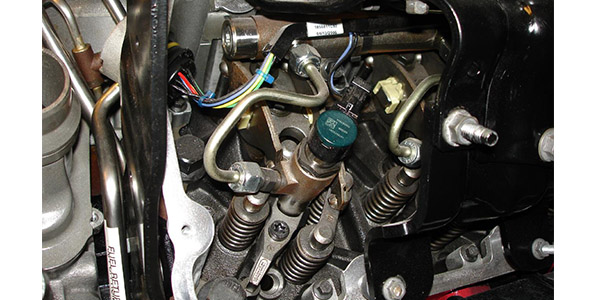

Ford Power Stroke Guide

Ford Power Stroke diesel engines have a history that dates back to 1994. The first in this series was the 7.3L engine, which was designed by Navistar for Ford. The 7.3L featured direct injection and turbocharging, and was probably the most reliable and durable engine in the series. The only major problems with these engines have been hard cold starts due to extreme valve seat wear or leaky O-rings on the injectors.

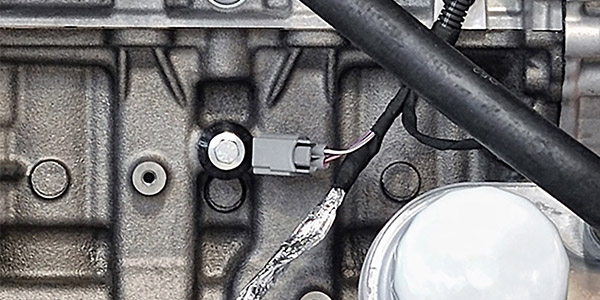

Knock Sensor Engine Diagnostics

The knock sensor is a piezoelectric accelerometer that acts as a microphone on the engine. It converts vibrations into an alternating current (AC) signal. When the crystal inside the sensor is vibrated, it produces an AC voltage. The greater the vibration or shock, the higher the voltage and frequency.