Ultimate Underhood: From Mechanical Fuel Injection to Putters

Mechanical constant stream fuel injection is the pinnacle of pure mechanical engineering. The mechanic setting up the system must optimize the amount of fuel for a given throttle position, rpm and engine load. By using different pumps, jets, linkages and metering block settings, it is possible to deliver the correct amount of fuel in large

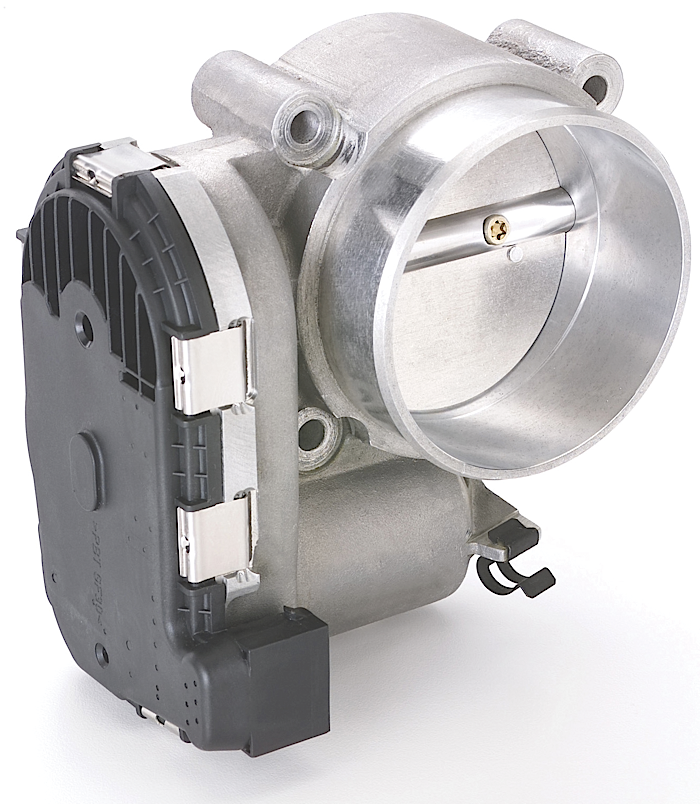

Induction Cleaning Service For Direct-Injection Vehicles

You may have seen it before: misfire codes, stumbling and suspicious fuel trim numbers. On a scan tool, the engine may show a loss in volumetric efficiency. The driver may complain about a loss of power, poor fuel economy, hard starts and a rough idle. But this is not a 12-year-old engine; it is only

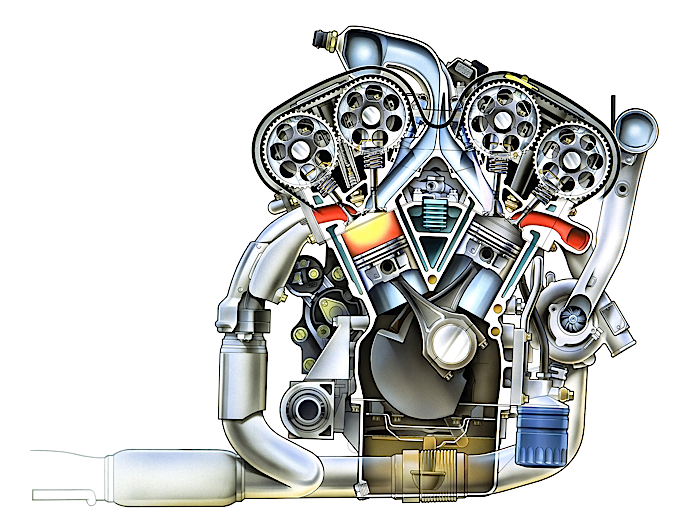

Getting the Complete Picture on Converter Efficiency

Engine management systems compensate for changes in engine speed, loads and temperatures by adjusting the amount of fuel injected, spark advance/retard and even when the intake and exhaust valves open. These adjustments can only do so much. Tailpipe emissions are cut further by exhaust gas recirculation (EGR) and secondary air injection systems. The last line

Directions: 20 Years: The Past, Present and Future of Underhood Service

Automotive historians will look back on 1995 as a watershed year for the automotive industry. By September, all 1996 models had to have the same OBDII diagnostic connector under the dash, speaking the same emissions language. Around the same time in Akron, OH, Babcox Media saw the times were changing for vehicle repairs and diagnostics.

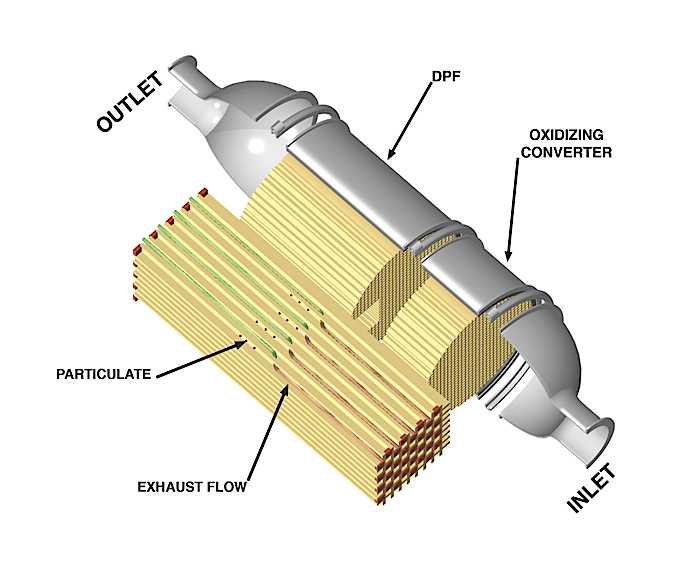

Diesel Particulate Filters

The EPA has lowered diesel fuel sulfur content from 500 ppm (parts per million) to 15 ppm. This new ultra-low sulfur fuel has been available since October 2006. All 2007 and later diesel engines must comply with the new regulations that require the reduction of nitrogen oxide (NOx) and hydrocarbons (HC) by 50% and particulate