When your customers start coming in for cooling fan issues this summer, your business will heat up fast. Before tackling these problems by trying to repair or replace the individual fan motor, consider replacing the entire cooling fan assembly. You’ll eliminate a lot of unnecessary steps, hassles and probably unbillable labor.

Fan motor replacements can take twice as much time as fan assemblies. You have to pull the assembly, remove and replace the fan motor, and then, refit the assembly. The real fun starts if the fan motor is attached by rivets or non-reusable fasteners. After years of use and temperature extremes, the plastic shrouds also tend to get brittle and can be easily damaged during the repair.

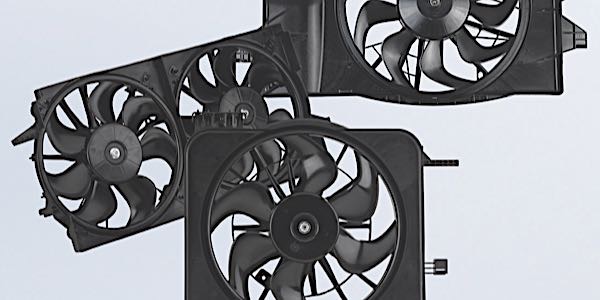

Not All Fan Assemblies Are Created Equal

In the past, your options were limited to the OE dealer or salvage yard, but today, you can get reasonably priced new aftermarket units. But, be careful because not all fan assemblies are created equal. Make sure your fan assembly is designed to meet OE specs.

The fan motor must be vehicle specific to deliver proper cooling airflow, otherwise, you may face an overheating comeback and risk serious damage to your customer’s engine. The connector and the shroud should be exact OE fits to avoid installation hassles. You also have to consider reliability and service life. An OE style fan motor can last up to three times as long as a ‘universal’ motor.

Cooling Fan Troubleshooting

Although you may be familiar with sorting out an overheating engine, here’s a few steps you can take after eliminating obvious issues such as low coolant or leakage, a faulty thermostat, fan blade damage or air-flow blockage:

- Test fan motor. Connect fan motor to 12-volt power supply and test for proper function.

- Check fan motor fuse. Replace if necessary.

- Inspect fan motor and wiring harness connection. Reconnect if necessary.

- Check the fan motor relay. Test for proper current at connector.

These helpful tips are brought to you courtesy of Continental, manufacturer of OE quality, VDO Cooling Fans. For more information, visit: vdo.com/usa or contact: [email protected].