There has been some confusion concerning piston ring seating. Some ring sets have been returned to the manufacturer with the comment “the rings didn’t seat,” however, when the rings were examined they had 360 degree continuous contact on the O.D. face. This contact is indicative of total ring sealing.

There has been some confusion concerning piston ring seating. Some ring sets have been returned to the manufacturer with the comment “the rings didn’t seat,” however, when the rings were examined they had 360 degree continuous contact on the O.D. face. This contact is indicative of total ring sealing.

So when is a piston ring actually seated?

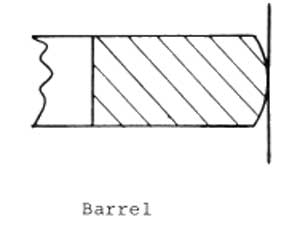

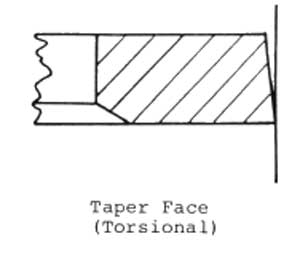

For a compression ring to seal against the cylinder wall it is important that line contact be established. The sketches below Illustrate cross sections of two popular types used in many ring sets.

As can be seen in the illustrations, both the barrel face and the taper face will initially only make line contact with the cylinder wall. The contact area will increase as ring wear occurs. However, under normal operating conditions, it will be many thousands of miles before the ring is worn to full O.D. face contact. In fact, when a ring is worn to full face contact it is near the end of its service life or has experienced some form of abrasive wear.

When proper cylinder finish is achieved during the honing process, the rings will line contact in a very short period of engine operation. The rings will then seal properly.

– Tech Tip courtesy of Hastings Piston Rings.