Getting Stoked to Service the 6.0L Power Stroke

If there were one engine that plagues the mid-size diesel world, you would have to say that it is the 6.0L Power Stroke. The 6.0L came into existence because the EPA demanded tighter emissions laws for diesel engines. Even though the 7.3L was branded as the reliable workhorse for Ford, it would never be able to pass the tighter emissions laws that were going to come into effect for 2004.

Tech Feature: Troubleshooting Internal Errors – Solving Piston and Ring Breakdowns

Rings that do not seal well during all four phases of the four-cycle combustion process can reduce an engine’s power potential by 20, 30, 40 or more horsepower, depending on the engine’s displacement, compression ratio and speed. Rings that leak during the intake stroke will reduce air velocity and volumetric efficiency.

Tech Tip: Getting Your (Piston) Groove Back

The piston ring set and the piston must be engineered to complement each other from a standpoint of clearance between the back of the piston ring and the bottom of the piston groove. This clearance is referred to as back clearance. If the clearance is not sufficient, severe engine damage can result when the piston and rings are installed in the engine.

Tech Tip: Ford Camshaft Tick Noise

Some of the affected vehicles built Jan. 17, 2006 and later equipped with the 3.0L 4V Duratec engine with exhaust camshaft-driven water pumps may exhibit a ticking noise from the left bank cylinder head with the engine at normal operating temperature.

Compression Ring Seating: When is a Piston Ring Seated?

There has been some confusion concerning piston ring seating. Some ring sets have been returned to the manufacturer with the comment “the rings didn’t seat,” however, when the rings were examined they had 360 degree continuous contact on the O.D. face. This contact is indicative of total ring sealing.

Tech Feature: Straight Up Look at the Vortec 3500 Straight-Five Engine

The five-cylinder was seen as a way to achieve better fuel economy and performance than the six, but with more power and torque than the four.

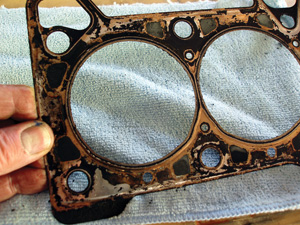

Cylinder Head Sealing – Gasket Surface Machining Is The Most Critical Area of Cylinder Head Repair

Early this year, I had a chat with a technical representative for a major aftermarket gasket manufacturer who shed some light on some of the problems facing the cylinder head gasket market. According to this representative, the relatively short production life of modern engines also shortens the time that an aftermarket gasket company needs to

Tech Spec: Tackling Old Timers – Salvaging Pre-War Era Engines

It’s often surprising to some people that parts for these cars are still available. For other engine specialists, it’s sometimes more surprising when they aren’t.

Tech Tip: Gaskets from Different Eras Vary Quite a Bit from More Modern Vehicles

When selling engine gaskets, the modern parts professional is often faced with a dizzying array of gasket technologies. The difference in gasket technologies among a ’50s-model pickup truck, a ’60s-vintage, high-compression muscle car and a modern bi-metal or aluminum engine is often quite dramatic.

Tech Tip: How to Check Piston Ring Groove Back Clearance

It is extremely important to check rings for sufficient back clearance to verify correct ring set application for the engine. The piston ring set and the piston must be engineered to complement each other from a standpoint of clearance between the back of the piston ring and the bottom of the piston groove.

Tech Tip: Top 10 ‘DOs’ of Piston Ring Installation

Here are 10 brief pointers from Hastings Piston Rings on how to properly install piston rings and avoid a comeback.

Tech Tip: Destroking or Decompressing Pistons

A destroked piston is a piston that may have as much as .020″ or more removed from the top of the piston. This may be done by machining the top of the piston, or reducing the thickness of the head in the original casting.