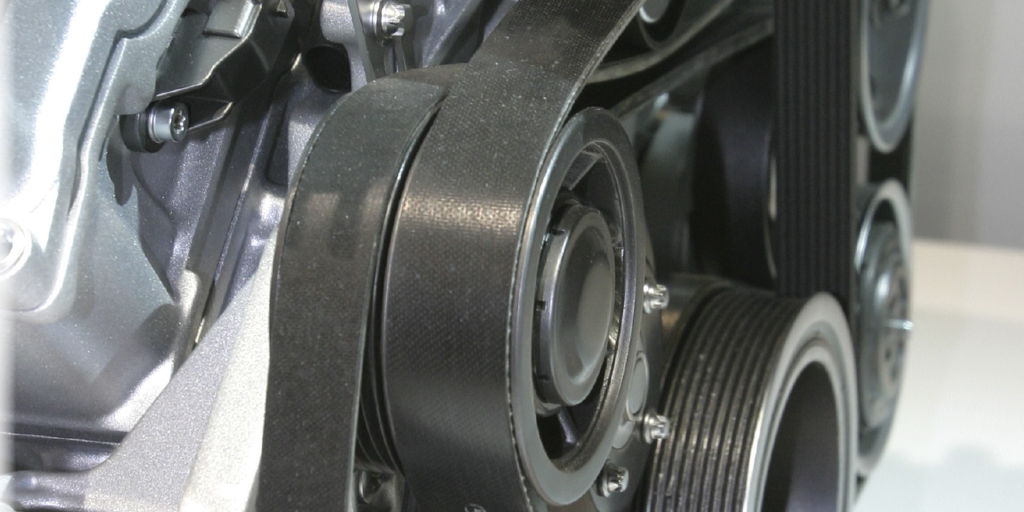

Belt alignment is key to the health of the belt. The belt drive system is designed to create friction between the grooves on the belt and pulley to transfer power from the crankshaft to the alternator, water pump or power steering pump. If the grooves on the belt do not align with the pulleys, the friction is not evenly applied. This causes wear and noise.

The first is a misalignment of the plane of the belt. This happens when a pulley is not parallel to the other pulleys on the belt drive system. This can cause wear to the shoulders of the belt and stress to the structure of the belt.

This type of misalignment often happens when components on the belt drive system are replaced. If the power steering pump is replaced and the pulley needs to be transferred, the pulley needs to be installed at the right depth. If it is not aligned, the belt might make a squeaking noise and eventually cause abnormal wear to the belt. For alternators, the case dimensions or pulley might not match the original alternator and cause an alignment problem.

Other rare causes for misalignment could be a separation of the crankshaft dampener or crankshaft developing endplay. If the crankshaft has excessive endplay, it could indicate other problems with the engine.

The other type of misalignment is the angular alignment of the pulleys. This causes the pulley to rotate on an axis not perpendicular to the rotational plane of the pulleys. The most common cause of this alignment is worn bearings. The bearings could be in idler pulleys or components driven by the belt. The worn bearings can cause the pulley to be cocked to one side. The second most common cause is a worn tensioner. The wear occurs between arm and shaft. The most common sign is an uneven gap between the base and arm.

Inspection

The first point of inspection is the belt. With your ear, listen for the most common noise: a chirping noise. Wear or damage to the shoulders of the belt is the first visual clue. Second, look at the tensioner and the alignment of the tensioner’s arm. Third, remove the belt to inspect the entire length and to rotate the pulleys and idlers for roughness and play.

With the belt off, you can check the alignment with specialty tools. The most basic tool is a machinist’s straight edge. There are other specialty belt alignment tools that use rods or even lasers to check pulley alignment.

Specifications from the OEMs on belt alignment are not typically published. The issue with the specification is different degrees of misalignment affects the given length of the belt run.