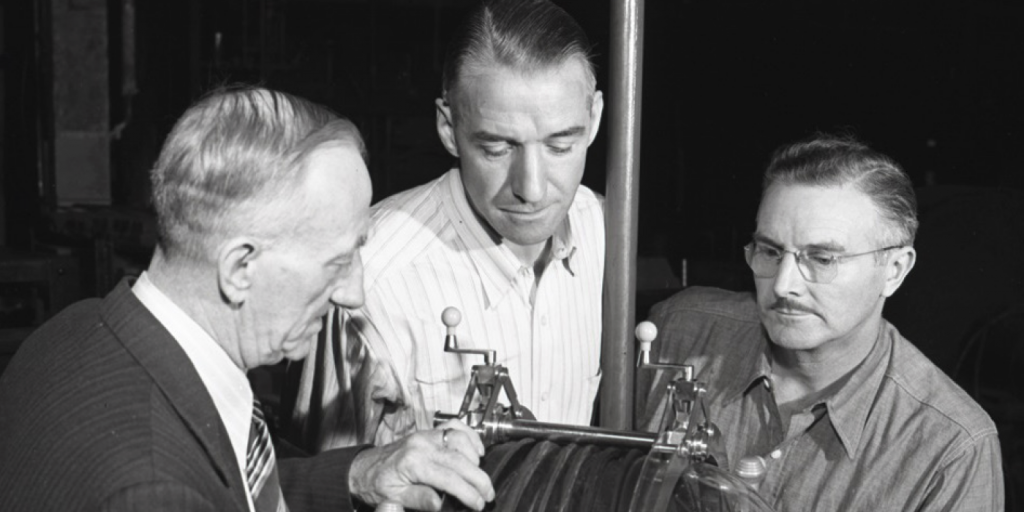

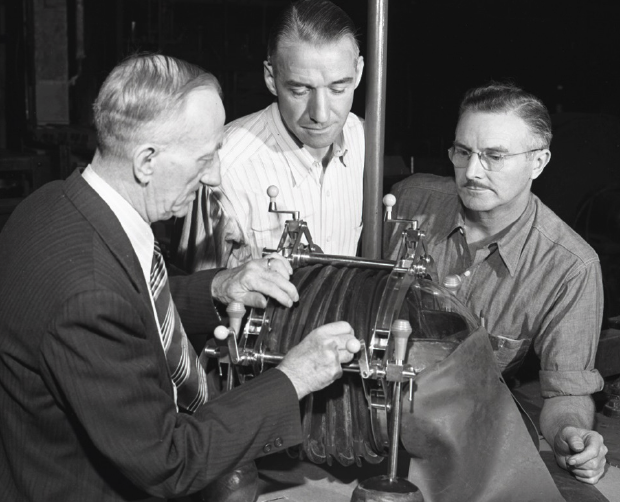

By the late 1940s the Polio crisis was rising in the U.S. Just like the current COVID-19 pandemic, Ford’s engineering and manufacturing capabilities were turned to developing medical equipment. At Ford’s Rouge plant, the Plastics Plant, Production Engineering, and Tool & Die departments combined talents to produce an iron lung for polio victims between the ages of seven and twelve years in just ten days. Meanwhile, the Special Machine Design section of Production and Processing Engineering, was working to develop a new electronically operated cradle that would rock the chamber containing the patient back and forth about five degrees to help maintain normal blood circulation in the polio victim.

These improvements to the iron lung machine were small but impactful. Ford engineers were also able to develop an “inspection window.” A full-length plexiglass window placed in the upper part of the “lung” would allow nurses and doctors to view the patient without removing them from the machine. These new features allowed for the ability to properly treat patients and provide the best care possible.