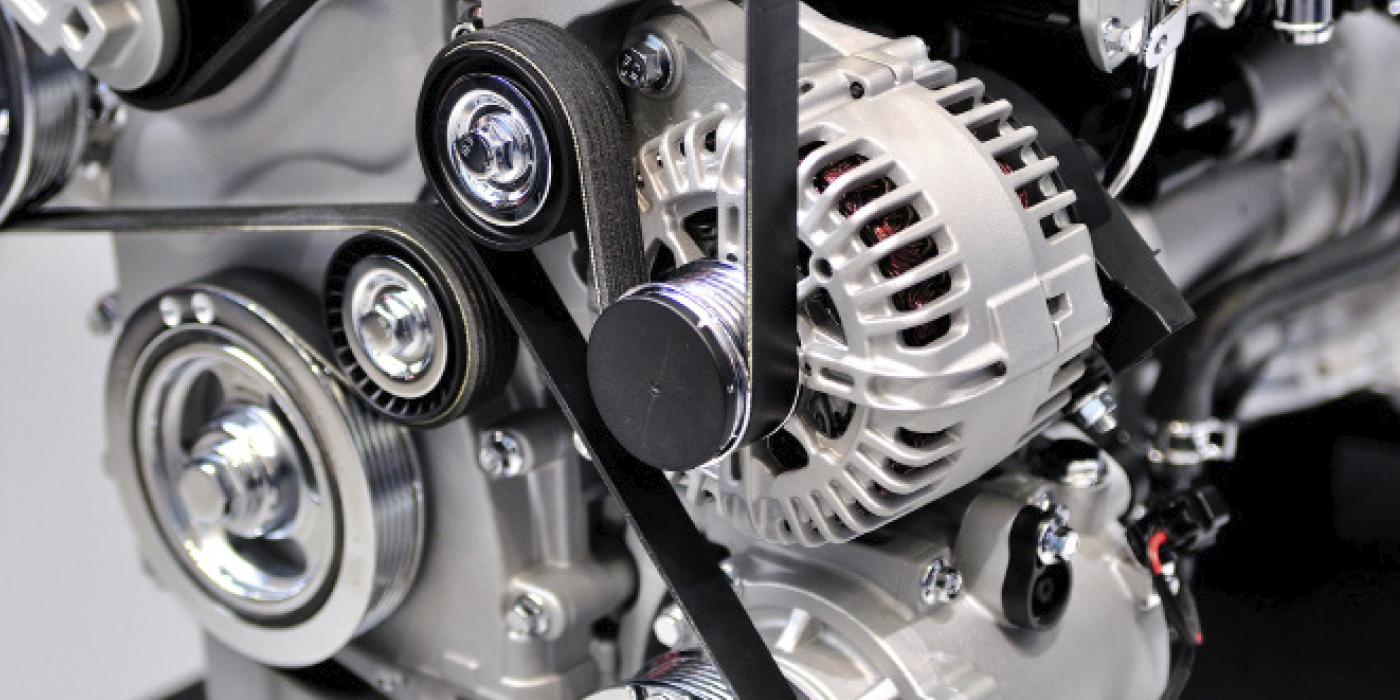

A worn automatic belt tensioner has consequences beyond a loose belt. When an automatic belt tensioner wears down, the belt and attached accessories will start to take an extra pounding because the tensioner can no longer dampen the power pulses of the crankshaft. The effect on these components is similar to when a car has bad shocks that slowly destroy the suspension.

Inside some belt tensioners, unseen to most technicians, is a dampening mechanism that absorbs shock. Excessive chattering or tensioner arm movement is not only the result of poor spring tension, but also a worn dampener. This makes the tensioner a wear part with a limited life span.

Inspection

Inspection

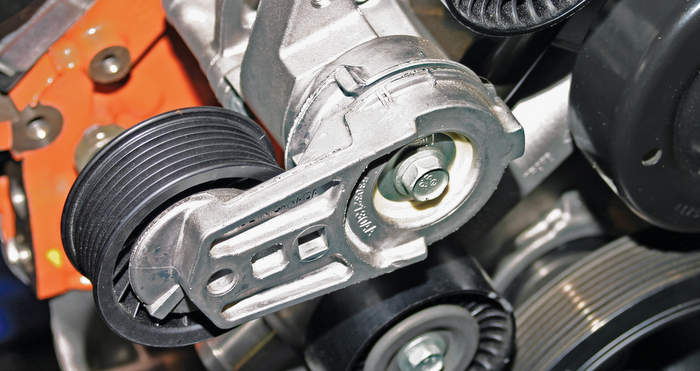

Inspect the outside of the tensioner for rust bleed seeping from inside the tensioner. This is an indication that the dampener or other internal parts have failed and metal-on-metal wear is happening.

Place a wrench on the tensioner and move the arm its entire range of motion at least three times. Feel for spring tension along with a fluid motion throughout. Any sticking or notching movement may indicate a problem with the spring or pivot bearing.

The arm should move up and down. Any lateral movement could indicate a bad bearing or spring.

Spin the pulleys. They should spin freely without bearing noise. Check for any grease seepage or smudging around the pulley bearing. Seepage indicates that the bearing seal has been compromised and grease has leaked from the bearing. The pulley bearing will begin to make noise and eventually seize if not replaced soon.

Replacement

Replacement belts must be close to the same length as the originals. Low-quality replacement belts may not be the correct length and will push the tolerances of the tensioner. A belt that is too short, for example, will cause too much tension and put higher than normal loads on the bearings inside the alternator, power steering pump and water pump. A belt that is too long (just an inch or less) may slip, make noise and wear prematurely. All of this will cause the tensioner to work harder and fail sooner.