With 6 million Flex Fuel Vehicles (FFVs) on the road today, there’s a good chance that one has already been in your shop for service. The difference from the usual cars and light trucks you see is the FFV that pulls in today or tomorrow may have E85 as its primary fuel source, rather than gasoline.

As you may know, E85 is a blend of 85% ethanol and 15% gasoline. It’s a renewable and domestically produced fuel and cannot be used in a conventional gasoline-only vehicle. It is instead used in a FFV, which can typically alternate between two sources of fuel: E85, gasoline or any blend of the two.

Flex fuel vehicles have been around for some time — the first dates back to a 1908 Model T built by Henry Ford. Vehicle manufacturers started producing greater quantities of FFVs in the 1990s, however, consumers who own them have largely used gas as the primary fuel source. Only recently has there been a growing awareness of FFVs and the benefits of using E85.

The appeal of E85 is that it stands to reduce U.S. dependence on foreign oil and reduce greenhouse gas emissions (GHG) by 15% to 20% compared to gasoline. The cost of E85 varies regionally. It is cheaper than gasoline in some areas, such as the Midwest, and more expensive in others.

The downsides are reduced fuel efficiency — 20% to 30% fewer miles per gallon — and the lack of E85 pump availability. According to the National Ethanol Vehicle Coalition, there are 1,200 pumps out of the 170,000 sites that sell gasoline in the U.S., meaning less than 1% of the nation’s gas stations offer E85.

In addition, safety standards continue to evolve. Currently, Underwriters Laboratories has suspended approval of E85 fuel pumps while they review their criteria. And experts suggest the safer nitrogen-based EVAP testing equipment OEMs use on standard vehicles may be even more important on flex fuel vehicles.

According to the U.S. Department of Energy, 90% to 95% of all ethanol made in the U.S. is made from corn. There are 114 ethanol biorefineries in the U.S., with another 78 under construction and seven undergoing expansion. The horizon points toward using the cellulose in agricultural wastes, known as cellulosic ethanol, although the technology to do this is still in its infant stages, according to the Renewable Fuels Association. Cellulosic ethanol is expected to reduce GHG by approximately 70% and will deliver four to 10 times the energy of today’s corn ethanol.

In the U.S. market, FFVs are produced by a handful of automakers: primarily DaimlerChrysler, Ford and GM. Mercedes-Benz and Nissan have FFVs in limited models. They are usually priced the same as gasoline-only vehicles, although industry sources say vehicle manufacturers will spend an additional $100 to $200 to produce a FFV.

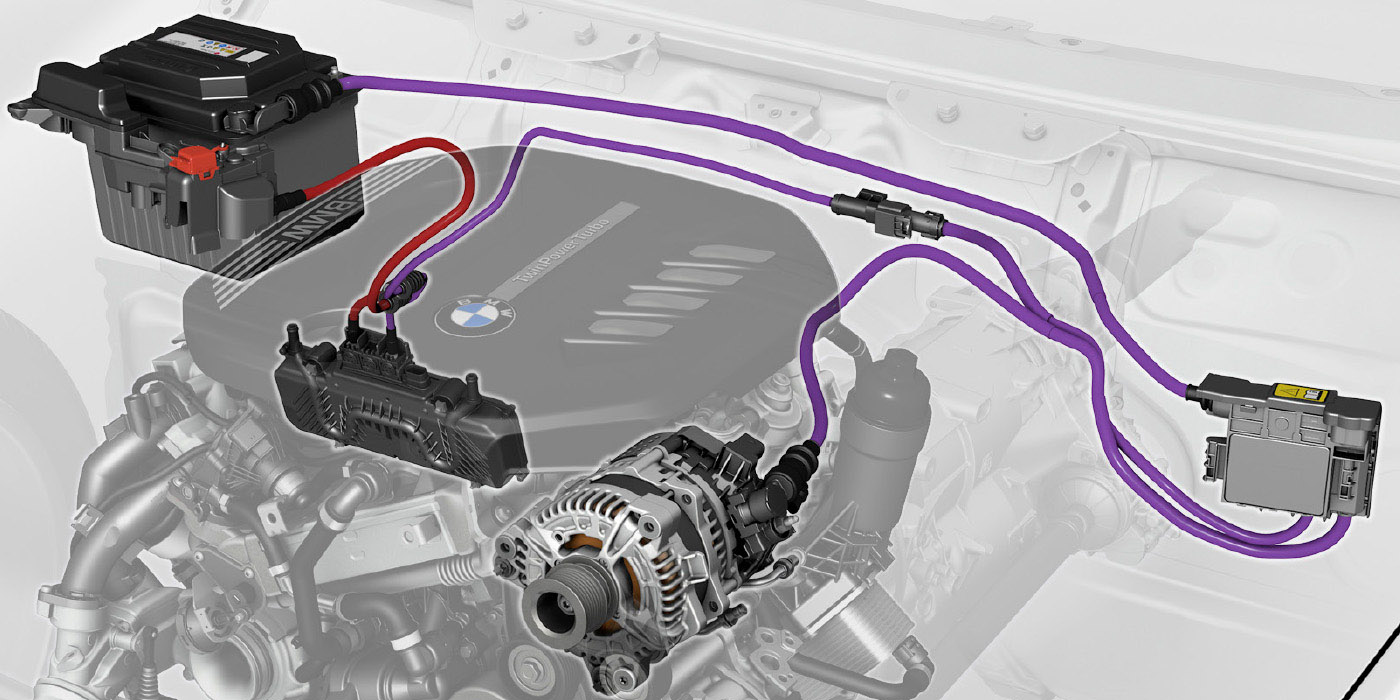

These costs allow automakers to ensure that the fuel tank, emissions equipment, fuel injectors, sensor and other materials are in place as needed to ensure a vehicle can work reliably on E85.

In the future, the Big 3 plan to double the annual production of FFVs to 2 million by the year 2010. Nissan plans a larger rollout of its existing FFVs, while Toyota, Honda, Mitsubishi and Porsche are also studying FFVs and planning limited production.

The most discussed reason for automakers to produce FFVs pertains to Corporate Average Fuel Efficiency (CAFE) requirements. Brazil’s use of FFVs and adoption of E85 is often cited as a model for the U.S. to follow. There are eight automakers that produce 43 models of FFVs in Brazil. In early 2006, the country announced that it no longer has to import oil from the Middle East or anywhere else. A key to Brazil’s success is that consumers are choosing ethanol rather than being forced to buy it.

There are many industry groups that support E85 and a wealth of resources that provide information about E85 and FFVs. At the start of the 110th Congress, a number of bills were introduced to support the use of E85 and the development of FFVs. State legislation has also been introduced to provide tax credits for consumers who buy FFVs. Some states already provide tax incentives for consumers, refueling stations and alternative fuel vehicle manufacturers and retrofitters.

Phil Sasso is president of Sasso Marketing, Inc., an aftermarket marketing service firm. Sasso, a sales and marketing writer, speaker and automotive industry consultant, hopes to soon be driving an FFV. Subscribe to his free marketing tip e-mail at: philsasso.com/blog.