When a driver sets a temperature in the control head of an HVAC system, what does it mean to the vehicle? Seventy-two degrees could mean many different settings depending on the outside temperature, humidity and even the position of the sun.

When a driver sets a temperature in the control head of an HVAC system, what does it mean to the vehicle? Seventy-two degrees could mean many different settings depending on the outside temperature, humidity and even the position of the sun.

When a passenger decides that 70 degrees is a better temperature for their zone, things get even more complicated. Automatic Temperature Control (ATC) systems require a complex array of internal and external sensors that include ambient air temperature sensors, interior temperature sensors, outlet duct and evaporator temperature sensors, pressure sensors, humidity sensors, blend door position sensors and sunload sensors.

On Thursday, Nov. 1, nearly 5,000 Auto Value and Bumper to Bumper automotive professionals wearing matching yellow shirts will begin their “festive walk” from the Mirage hotel to AAPEX 2018 at the Sands Expo, temporarily shutting down the busy Las Vegas Boulevard along the way.

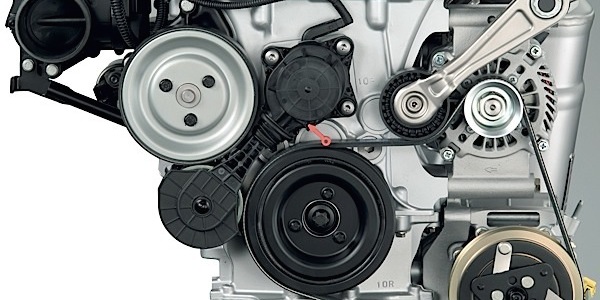

You might have only one chance to sell a customer a new serpentine belt. With belts lasting roughly 90,000 miles, proper inspection at the time of failure is critical not only for selling the belt, but also for ensuring add-on sales and better customer satisfaction.

Andrew Markel introduces an inexpensive tool that can assist in selling cabin air filter replacements. Sponsored by Auto Value and Bumper to Bumper.

Air conditioning odors typically result from the uncontrolled growth of bacteria and other microorganisms in the evaporator. Research by independent laboratories has found fungi such as Aspergillus, Cladesporium, Penicillium and others growing on cooling coils and other A/C system areas.

HVAC control modules may fail when the contacts and switches become inoperable. Sponsored by The Group Training Academy.

Among the new products is an OE FIX climate control module designed to fit 1.7M Chevrolet Express & GMC Savana vehicles.

Air conditioning scents can come from a host of things.

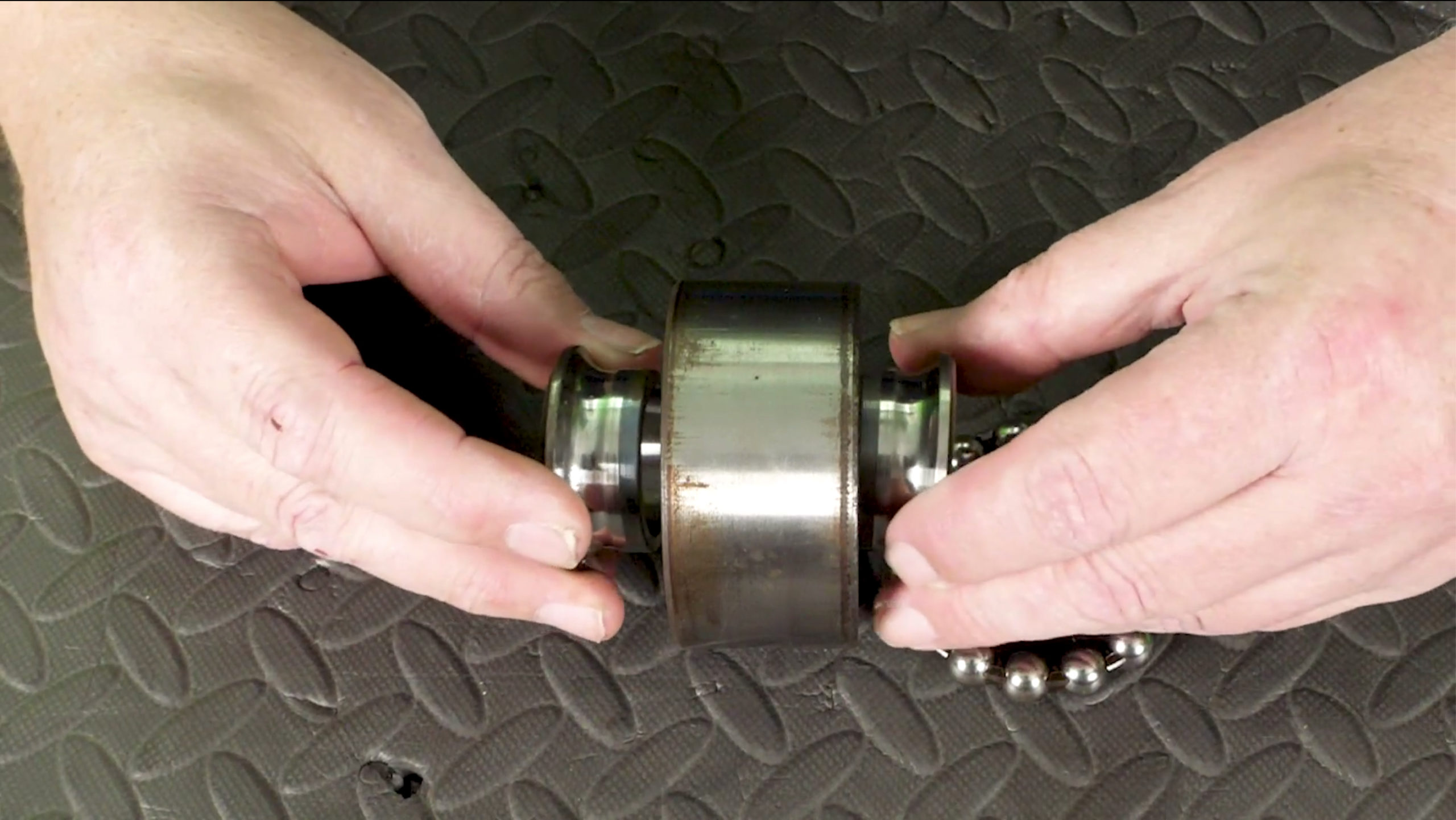

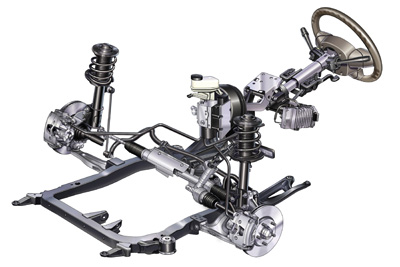

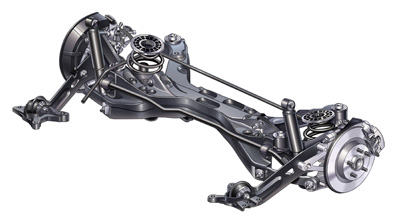

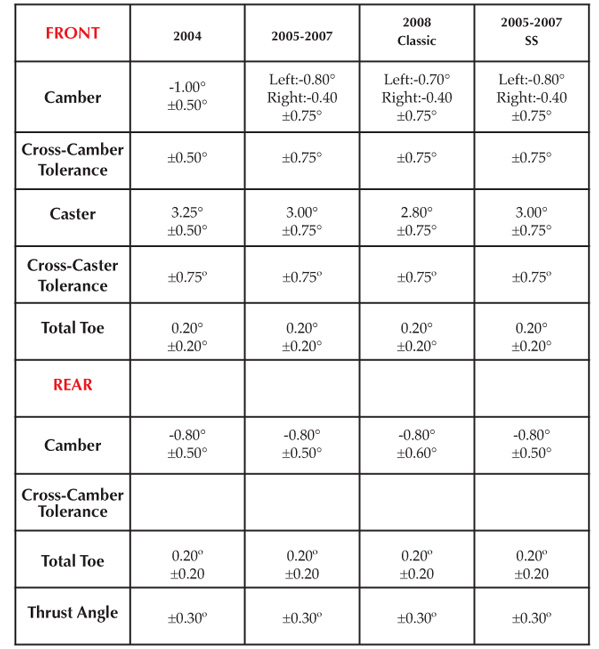

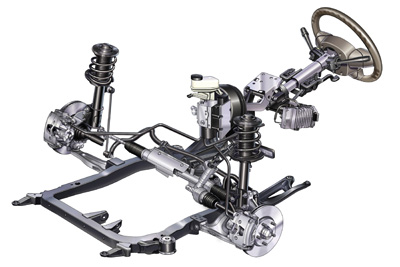

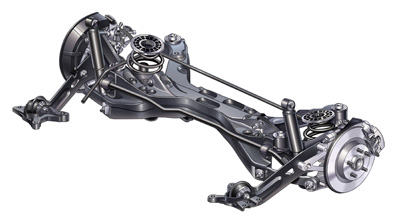

If you’re replacing a wheel bearing, you should also check the alignment. This video sponsored by GMB.