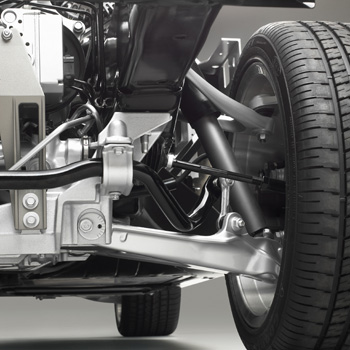

First, technicians working on a C5 Corvette suspension need to remember that the knuckles, upper control arms and ball joints can be damaged if they are not tightened using the correct procedure. Knuckles and upper control arms are aluminum and can be damaged if a torque wrench and torque angle gauge are not used. No matter if you go too tight or too loose, if you fail to use correct tools and procedures, you could be buying the customer a knuckle and working for free to install it.

First, technicians working on a C5 Corvette suspension need to remember that the knuckles, upper control arms and ball joints can be damaged if they are not tightened using the correct procedure. Knuckles and upper control arms are aluminum and can be damaged if a torque wrench and torque angle gauge are not used. No matter if you go too tight or too loose, if you fail to use correct tools and procedures, you could be buying the customer a knuckle and working for free to install it.

The torque spec for the ball joints is typically between 15-30 ft/lbs and torque angles are between 140º and 225º. Never guess or try to use your calibrated elbow; always look up the spec and use a torque wrench. The same procedure is also required for tie rod ends. Also, make sure the washers on the studs are in good condition and installed in the right direction. If a washer splits or fails, it could cause a catastrophic failure.

The torque spec for the ball joints is typically between 15-30 ft/lbs and torque angles are between 140º and 225º. Never guess or try to use your calibrated elbow; always look up the spec and use a torque wrench. The same procedure is also required for tie rod ends. Also, make sure the washers on the studs are in good condition and installed in the right direction. If a washer splits or fails, it could cause a catastrophic failure.

Second, technicians need to be aware that the Corvette uses thread locking compound on some suspension bolts. Make sure you clean the bolt and reapply the compound.

Last, you will not find a spare tire on a C5 Corvette. All models came with run flat tires and TPMS systems. But, sometimes even the most safety conscious customer will not replace the run-flat tires due to the cost and harsh ride.

Inspection

Before the readings are taken, take the Corvette for a test drive. Listen for any noises like clunks and bangs. While rolling, put the vehicle into neutral to listen to the wheel bearings. Due to the cornering forces the Corvette can generate, the wheel bearings can take a lot of abuse. Heavy-duty replacement hubs and bearings are available with larger races and extra bearings.

Driving the C5 Corvette onto a drive-on lift that is not set up to handle low-slung cars can be difficult. This is one car that may make you realize the limitations of your lift; take your time.

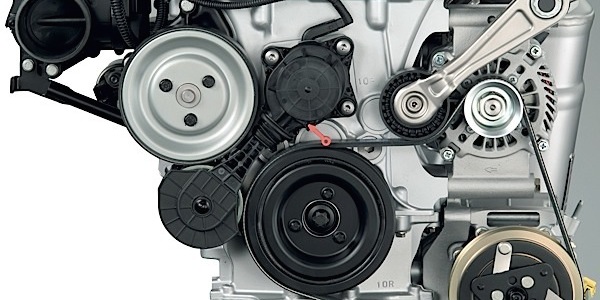

On the lift, inspect the general condition of the suspension. Pay special attention to the sensors and linkages for the “active damping” system on some models. The linkages can be damaged by road debris.

Ride Height

Ride Height

Make sure you measure the ride height before you take any readings. The Corvette does not use coil springs. Instead, it uses composite material springs mounted transversely. Bolts are mounted control arms to make the adjustment. Adjusting the ride height before an alignment can minimize adjustments for camber and caster.

Front

1. Set the tire pressures to the pressure shown on the certification label. Refer to Label – Vehicle Certification.

2. Check the fuel level. Add additional weight if necessary to simulate a full tank.

3. Make sure the rear compartment is empty.

4. Make sure the vehicle is on a level surface.

5. Close the doors and hood.

6. All dimensions are measured vertical to the ground of the bottom of the lower ball joint and center of the lower control arm’s mounting bolt. Trim heights should be within 13 mm (0.5 inch) to be considered correct.

7. Lift the front bumper of the vehicle up about 38 mm (1.5 inches).

8. Gently remove your hands. Allow the vehicle to settle into position.

9. Repeat this jouncing operation two more times for a total of three times.

10. Measure the distance between the lowest point of the lower ball joint and the center of the front side of the lower control arm mounting bolt.

11. Push the front bumper of the vehicle down about 38 mm (1.5 inches).

12. Gently remove your hands.

13. Allow the vehicle to rise.

14. Repeat the operation for a total of three times.

15. Measure the dimensions from both the right and left side.

16. The true height dimension number is the average of the high and the low measurements.

17. When adjusting the spring adjuster bolt, J42743 must be used in order to prevent damage to the rubber shear pad on the end of the bolt. One complete turn of the spring adjuster bolt is equal to 2 mm (5/64 inch).

Rear

Rear

1. With the vehicle on a flat surface, lift upward on the rear bumper 1.5”.

2. Gently remove your hands. Allow the vehicle to settle into position.

3. Measure the distance between the lowest point of the right rear ball joint (2) and the center of the front of the forward rear lower control arm bushing mounting bolt (1)

Measure both the right and left sides of the vehicle.

The true height is the average of the high and low measurements.

• One complete turn of the adjustment bolt is equal to 2 mm (5/64 inch).

Adjustments

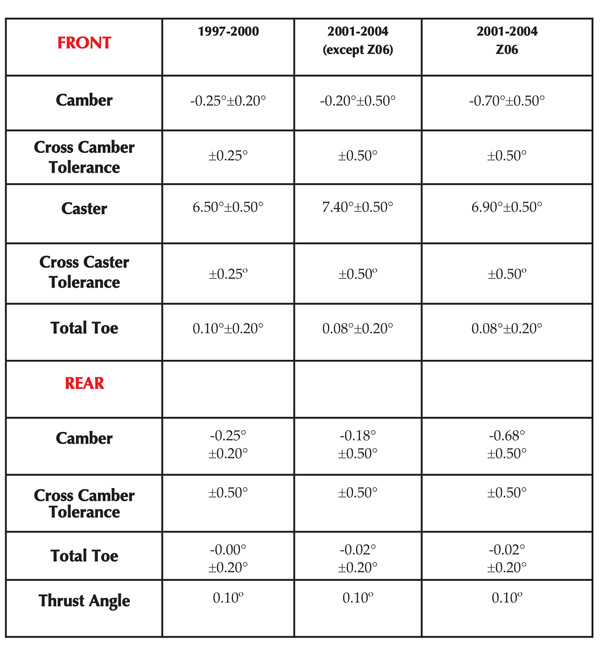

Once the ride height is set and initial readings are taken, camber and caster adjustments might be required. If the readings exceed the specifications and adjustment range, compare the controls and look for any deformation and changes in setback. Also, look at the cross camber and caster.

Camber and caster are adjusted by cam bolts in the lower control arms of the front and rear suspension. The bolts have a torque specification of 125 ft/lbs.

If the driver wants more negative camber because they think they are a racecar driver, it is possible. Adding or subtracting shims will change the negative and positive camber and caster settings. Make sure to use an equal thickness of shims on both sides of each individual upper control arm leg. Make sure to check the clearance between the upper control arm and the shock absorber in full rebound, if the shims are removed from the upper control arm.

Overall, the biggest problem in aligning a C5 Corvette is the owner in some cases. I hate to stereotype Corvette owners, but some the owners are suckers for some of the worse “bolt-on” modifications and advice ever created. But, they are also some of the best informed and enthusiastic customers in the world.

Make sure you ask the customer what they expect from the alignment. Some owners may come in with alignment specs from an internet forum that is radically different from stock specifications or a set of offset bolts for the upper control arms. Talk to them to find out how they use the car and explain how a part or procedure can negatively and positively impact performance.