Shocking, electrifying, polarizing, spark of excitement, flash in the pan. What do all of these words/phrases have in common? They’re all terms from the world of electricity or electronics used to make a point. That point is that electricity and electronics are pretty darn important to our lives. As I write this article, the horrible stories about storm victims in the Northeast are rolling in. The single most common problem from that storm is the lack of electricity. The reality is that we are almost 100% dependent upon electricity in our daily lives. This is especially true in relation to our automobiles.

Without electricity, none of us can make a living in the automotive aftermarket. As I writer, I depend on electricity to operate my computer, phone, etc. As a technician, you depend on electricity to operate most of your equipment.

I hope that this article provides you with some new ideas about tools and techniques for accomplishing the difficult task of diagnosing and repairing your customers’ vehicles.

As of this writing, I am sitting on a plane many miles above your shop, returning from the 2012 AAPEX and SEMA shows in Las Vegas. These tradeshows are the mecca for everything automotive — tools, toys, bling and everything else you can imagine. If it exists in the automotive aftermarket, OEM or manufacturing, it can be found at one of these two shows.

This year was no different in that we had the chance to see firsthand some of the newest and coolest tools available to technicians. There were tools ranging from the simple to the absurd. From ho hum to holy cow! Some things were new twists on old tools while some were truly new and ground breaking.

Multimeter Innovations

This is a tool that I was convinced had come as far as it was going to go. There are some amazing DVOMs available today. Ultra-high resolution, airbag safe, temperature recording, min-max, graphing, snap-shot (data capture) — all of these are features available on many good meters today. So what, right? Nothing new here, I agree! So what did I find that flipped my switch and something you should check out for yourself?

Well, the first new toy I found was a DMM with the ability to transmit via Bluetooth to your cell phone. With a free app you will be able to “read” the meter from anywhere in the shop (distance estimates are 500’). So what good is that, you ask? Think about hooking up your test leads to a brake light circuit at the back of the car, take your trusty phone and go sit in the driver’s seat to depress the brake pedal, activate turn signals, etc. You can “see” what is happening at the taillight right on your phone! Cool, huh?

The next goody is by the same supplier. This gadget has a different, although equally cool, super power. This meter can upload information via Wi-Fi to the Internet or a cloud-based server. This seems like overkill right? I thought so too, at first.  Now imagine you’re a technician for a fleet operator in a cornfield in Iowa. You’ve diagnosed a problem that requires the replacement of a very expensive component. You can now e-mail a snapshot of the test results to your corporate director of fleet maintenance for approval. Or…you’re a body shop owner and have determined after the initial estimate that the car needs a new head light assembly at a cost to the insurer of $1,800. Wouldn’t it be nice to be able to include the test results to convince the company to approve the addendum to the claim?

Now imagine you’re a technician for a fleet operator in a cornfield in Iowa. You’ve diagnosed a problem that requires the replacement of a very expensive component. You can now e-mail a snapshot of the test results to your corporate director of fleet maintenance for approval. Or…you’re a body shop owner and have determined after the initial estimate that the car needs a new head light assembly at a cost to the insurer of $1,800. Wouldn’t it be nice to be able to include the test results to convince the company to approve the addendum to the claim?

So, it turns out that there are new and innovative ideas and new things under the sun! (For specific tool names, send an e-mail to jclements @babcox.com.)

The next tool, while admittedly not completely new, has so many new abilities that I am going to call it new. This is definitely one of the hottest new tools on the market and one you should plan on adding to your collection. For years, a supplier has offered a tool that allows you to test electrical components for both ground and power. This tool, which I would bet you or someone in your shop owns, can also inject power into a circuit to see if a component works. This tool is one of the most popular and widely used electrical test tools on the market today. This is another tool that I would have bet could not be improved upon. Boy, would I have been wrong!

Imagine the original tool, but now it has some new abilities. First, and perhaps the most impressive, is the addition of auto sensing and auto ranging. Now before you start yelling “foul!” I know, these are not new abilities for multimeters. There are several really good meters on the market today that have these capabilities. The difference here is that supplier has combined this with the original tool. In my estimation, this tool went from being just a bruiser with the ability to pound a circuit with power, to being a thinker capable of deciding what force is needed or the lack thereof to get the job done.

This sophisticated tool can detect the presence of power, as well as determine what range is needed to best read the power. The tool will automatically be ready to display volts, read resistance, etc.

The next improvement from the original design is the tool’s ability to read and interpret voltage and resistance variations in a “loaded” circuit. This is an important and often overlooked step during diagnosis. How many times have you tested a circuit that passed to later identify and condemn a component or wiring in that same circuit? So what did you miss? You tested for power, ground, switching, etc. Everything worked as specified. You failed to “stress” the circuit and evaluate resistance on the circuit during that stress.

This new tool does just that; it applies high current while watching resistance to simulate real-world operating conditions. By looking at a circuit in both a stressed and non-stressed condition, you are far more likely to find those pesky problems like burnt relay contacts, internal corrosion and loose grounds. If you don’t consider any other tool after reading this article be sure to check out this amazing new product.

Scan Tool Advances

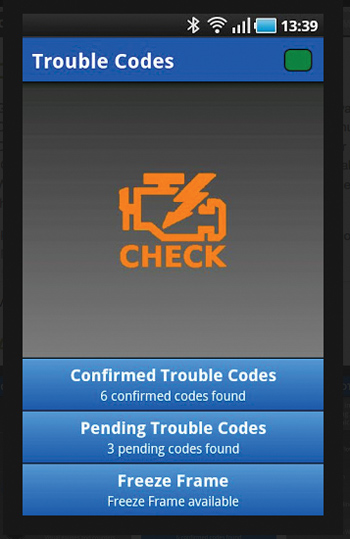

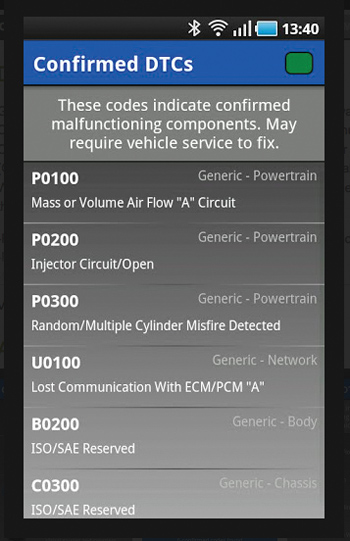

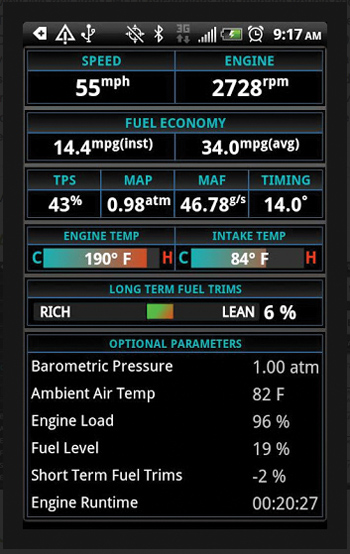

There was no shortage of diagnostic scan tools available at the shows this year that you might want to consider adding to your collection. One common theme among the new entries is the combining of testing with communications. With either or both of the Wi-Fi and Bluetooth protocols, you can find and distribute the information you need to read, interpret, format, program, adjust and record data to your heart’s content.

Scan tool manufacturers now realize the need to facilitate the technician surfing the Net. Whether to interpret a code, find a fix or download software, Internet access is no longer just a “nice to have,” it is a “must have.” Once thought of as a toy and a distraction, Web access is an important feature to ask about when shopping for scan tools.

We are seeing three common themes with all the major manufacturers of diagnostic equipment. The first is the addition of devices built on tablet infrastructure. With the unrivaled success and near universal acceptance of products made by our favorite “fruit” electronics manufacturer, it just makes sense to follow suit with scan tools that use the familiar type of interface.

Having said that, to date, none of the tools we have seen actually use hardware produced by the electronics giant. Instead, everything uses either off-the-shelf tablets or custom-built hardware designed by auto diagnostics suppliers. It would seem that the cost is just too prohibitive currently to make sense yet. In most or all cases, these tools will feature touch technology just like the phones and devices we use every day in our personal lives.

One of the largest suppliers told us that they absolutely have built their menus and interfaces to mimic the look and feel of the screens we see every time we grab our phones to make a call or send a text. To paraphrase the supplier: “Why try to reinvent the wheel?

As cell phone users, we already ‘get it’ — we understand what the logos and icons mean on our phones. Why not use that same flow and feel to operate our scan tools? These tools are complicated enough without asking the operator to learn a new way of navigating and a new bunch of symbols!” Sounds like an example of a proactive supplier listening to feedback from their customers! Well done!

The second recurring theme we are seeing is reduction in size. This also seems to be following the big electronics suppliers in terms of making scan tools closer to the size of mid-size tablets and smartphones. This can make sense for most technicians while it does strain the eyesight of us old guys!

One last development we are liking is the isolation of functions into separate scan tools and testers. One supplier has created choices for customers to include both all-inclusive master tools as well as single-purpose tools that are in many cases both smaller and lower priced. This gives you the option of just buying the tool or tools you need for your shop. Maybe you only need ABS functionality as a brake specialist. Now you can buy just a tool for reading and clearing those types of codes versus a tool that can talk to every system on the car. This is just one example of the choices available to you when shopping for scan and diagnostic tools.

The above are just a few of the many new tools and equipment available to you for working on and diagnosing vehicles electrical and computer systems. Be sure to ask your tool and equipment distributor about these great new products.