If an A/C system is found to contain sludge or black gunk, it means everything in the system is contaminated and must either be cleaned or replaced.

If an A/C system is found to contain sludge or black gunk, it means everything in the system is contaminated and must either be cleaned or replaced.

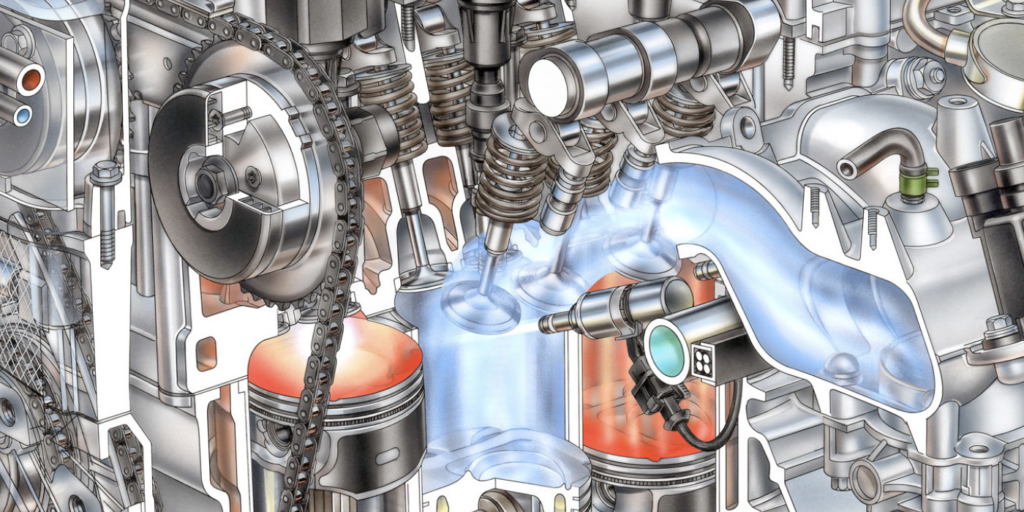

The A/C compressor is a pump that compresses and circulates refrigerant within the A/C system. Some have pistons inside while others have rotating vanes on an eccentric or a pair of metal scrolls or spirals around an eccentric. Many late-model vehicles have “variable displacement” compressors that change the piston stroke to increase or decrease the volume of refrigerant flowing through the system. Some of these run continuously instead of cycling on and off like conventional A/C compressors.

With operating pressures up to several hundred pounds per square inch and operating temperatures of several hundred degrees, all types of compressors really take a pounding. To survive in this kind of operating environment, the compressor needs plenty of lubrication and the correct compressor oil. The system must also be free of acids, contaminants and sludge.

Over time, loss of refrigerant, loss of lubricant, lubricant breakdown, system contamination, and/or loss of cooling efficiency (plugged condenser or an inoperative cooling fan) can lead to compressor failure.

A catastrophic compressor failure is bad news because flakes of metal can be spewed out of the compressor into the inlet and outlet hoses and condenser. If the system is not thoroughly cleaned and/or the condenser replaced, the debris may clog the orifice tube causing a loss of cooling, or it may contaminate the new compressor causing it to fail.

If an A/C system is found to contain sludge or black gunk, it means everything in the system is contaminated and must either be cleaned or replaced. “Black Death” occurs when moisture enters the system, reacts with the refrigerant and oil to form acids and sludge. The resulting black gunk can clog the system or damage the compressor.

Some components such as hoses and the evaporator can be safely cleaned using an approved A/C flushing chemical. Single tube serpentine-style condensers can be flushed but not parallel flow condensers.

Additional parts that should be replaced following a compressor failure include:

● Condenser (unless the original is a serpentine style that can be flushed);

● Orifice tube; and

● Accumulator or receiver drier.

In addition, your customer will also need the type of compressor lubricant specified by the compressor manufacturer, and R134a refrigerant to recharge the A/C system.

Newer vehicles (1994 & up) that are factory-equipped with R-134a refrigerant require various types of PAG (polyalkaline glycol) oil. There are several different viscosities of PAG oil ranging from 46 to 150, so make sure your customer gets the correct type for his compressor. Using the wrong type of PAG oil can cause premature compressor wear and failure.

If an older vehicle is being retrofitted from R-12 to R-134a, POE (polyester) oil or the specified PAG oil must be used instead of mineral oil. Mineral oil should only be used in older R-12 systems (although some new compressors are shipped with a small amount of mineral oil inside to prevent a dry start).

Replacing an A/C compressor requires thoroughly evacuating the A/C system with a high vacuum pump to remove all traces of air and moisture after the compressor has been installed. If this is not done, air can displace refrigerant preventing the system from cooling normally. Air contamination will also make the compressor noisy.

The drive belt that turns the compressor should also be inspected and replaced if worn, cracked, glazed or oil-fouled.