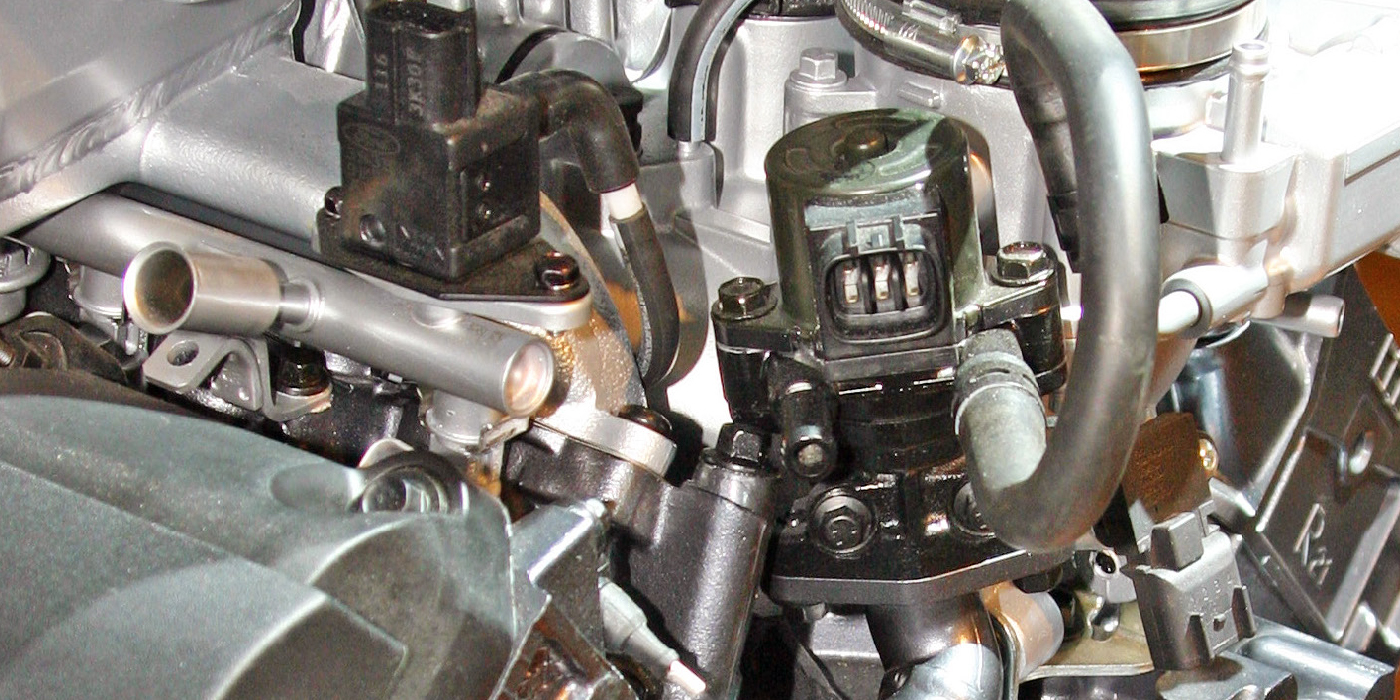

In 1994, select Toyota, GM and Ford models were sold with OBDII emission systems. To the amazement of many technicians, all of these models came with the same diagnostic connector called the data link connector or DLC. In 1995, 40 percent of vehicles sold had a common DLC. By the 1996 model year, all vehicles sold in the U.S. had the same diagnostic connector.

Unlike previous diagnostic connections, this 16-pin trapezoidal connector was based on an SAE standard. Automakers all had to comply with this standard or they wouldn’t be able to sell a car in 1996. The truly revolutionary part was how the new language used between the scan tool and the vehicle standardized the protocols for emissions information.

For two decades now, the DLC has remained under the dash and changed the aftermarket in ways people never anticipated.

Imagine a world without parts stores scanning for codes. This would be a blow to oxygen sensor and EGR valve manufacturers. These parking lot diagnostics have changed the way people perceive technicians and diagnostic time.

Insurance companies would not have a way to monitor vehicles with OBDII port devices through backward-compatible telematics systems. Many scan tool companies would never have started due to the cost of engineering hardware and software for different manufacturers.

What is the future of the DLC? Chances are the shape of the connector will not change, but the pin out designation could. Most vehicles have at least three open positions, and maybe one of these pins will carry telematics information in the future.