1. You don’t inspect shocks and struts.

Are you just looking for catastrophic damage? Do you only look at the shocks and struts when the driver complains of a noise or when the vehicle can’t be aligned?

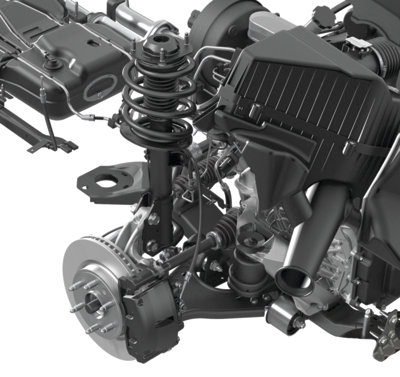

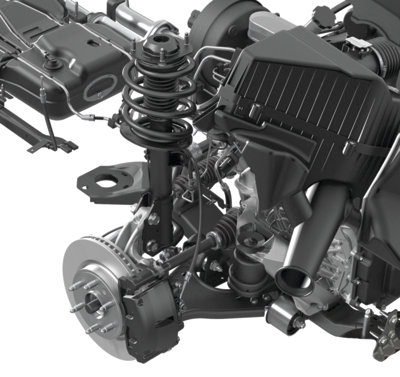

The first step in selling ride control is the inspection process. A visual inspection of the shocks and struts can tell you a lot about the state of the ride control units. This is a chance to make sure the vehicle is road-worthy before you put your own life at risk.

Look for signs that the units might be leaking oil, such as accumulation of road grime or oil inside boots and dust shields. Keep an eye out for “witness marks” that indicate the suspension might have bottomed out recently. Make sure all bushings and hardware for the ride control units are still on the vehicle.

Walk around the vehicle and perform the tried-and-true “knee-on-the-bumper” test. This test is not conclusive on its own, but it is a chance to quickly look for abnormal behavior. If you notice binding or looseness, or if the vehicle does not return to the original ride height, there could be a problem with the ride control components.

2. Your test drives need work.

When you don’t perform a test drive, you are not using your most powerful ride control tool: perspective. A technician or service writer behind the wheel brings fresh senses to the vehicle that haven’t been dulled by thousands of miles.

Before the test drive, you should have a clear list of symptoms and related conditions the customer might be experiencing. On the test drive, you should have a clear and methodical plan that inspects for ride control component replacement and other unperformed repairs.

A good test driver will be able to observe conditions or problems with the vehicle that have developed so slowly the owner is unaware of them — like degraded shocks and struts. One of the keys to becoming a good test driver is to find a driving “loop” or route that has a variety of road conditions. A predetermined loop adds a consistency that helps you spot small problems.

For suspension road tests, your test loop should consist of sections: a flat and straight section; an area to test braking and acceleration; an area with a dip or bump; and an area that offers both left and right turns.

Use a parking lot or rarely used section of road for the braking and acceleration section of the test. This test is used to detect brake pulls, torque steer and worn or loose suspension or steering components. Check for excessive nose-diving during braking. This is not normal and may be caused by worn springs or other ride control components.

Excessive suspension bouncing may be the result of weak shocks; bottoming out of the suspension may be the result of weak springs. Check for steering difficulties that may be the result of mechanical binding or interference.

Any excessive body sway could indicate worn springs, shocks or stabilizer assemblies. Listen for any excessive tire squealing during turns. This can be caused by incorrect alignment settings or a turning angle out of specifications.

Developing a methodical and consistent test drive loop and procedure can improve your chances of coming back from a test drive with an understanding of the problem the owner is experiencing. Also, a plan and a loop can eliminate distractions that could lead to an accident.

3. You don’t use an inspection form.

The technician should be supplied with a checklist to make notes. Some ride control manufacturers can provide you with printed forms. These forms help the salesperson be more confident in the selling process.

A complete inspection lays the groundwork for excellent customer communications and increases the possibility of a sale. The results of the inspection can help personalize the sales pitch to the individual customer.

4. You chicken out on the recommendation for loaded struts.

Even if the customer does not buy today, the inspection form, sales approach and pitch will likely stick with the consumer longer than the generic “recommend loaded struts.” They are more likely to return, which means your efforts will not be in vain.

5. Your car is in need of a ride control tuneup.

To increase your confidence in selling loaded struts, have new units installed on your own vehicle. You will be amazed at the difference if your vehicle has more than 50,000 miles. Also, you will sell more units because you have a better view of the perceived value.

Some ride control manufacturers help you by holding local clinics where you can drive vehicles in different states of ride control degradation. These events are typically held in parking lots on specially designed courses that magnify certain vehicle dynamics at low speeds. These events can energize a shop to sell ride control products more effectively.

6. You are afraid of losing a tire sale.

Tires are not cheap. When you get close to the sale, are you afraid to recommend new shocks and struts because the customer might bolt for the door when they hear the price for new loaded struts? You shouldn’t be. New shocks and struts protect the investment in their tires.

By the time a vehicle is ready for its second or third set of tires, it is time for new ride control components. This is based on mileage and the expense and premature wear that degraded ride control can have on new tires.

7. You use your squinted eye and thumb to check ride height.

OEMs include ride height specifications and measurement procedures in their service information for many reasons. The main reason is that springs wear out. The ride height also can be used as a diagnostic tool to determine the condition of the suspension. This involves more than your thumb and one closed eye.

Research the factory methods and specs to properly measure ride height. Neglecting to do this can affect the life of the shocks and struts and all angles of alignment. Among other considerations, engineers design the chassis and ride control components so that the ride height places the suspension at a particular point midway in its travel. Midway is not always the center, however.

Most springs are made of metal. As a simple example, take a coat hanger or welding rod and bend it in the same area several times. It will eventually break from metal fatigue.

8. You start at the bottom and try to work your way up.

Do you play it safe? Do you start with the least expensive option and try to work your way up? When selling ride control components, it is an effective sales tactic to start with premium products first rather than the economy or less-expensive option. This gives you a little room to provide the customer options that meet their budget and vehicle life expectancy.

Chances are that the customer wants the best. Starting the estimate with the least expensive alternative can lower your profit. Sure, quoting the lowest price might get some customers in the door, but it may leave some customers wanting more.

9. You hate hearing “no.”

It has been estimated by one shop that 50 percent of its ride control sales happen on the second visit. This means a large percentage of its first time sales pitches for ride control were shot down on the first try.

Don’t give up.

10. There is no incentive to sell loaded struts and shocks.

First, try increasing at least the number of ride control component inspections and recommendations to customers. Next, set a sales goal.