It was a scenario to which we can all relate. A long-time customer passed away and his vehicle was being gifted to his granddaughter. The 2009 Murano was dropped off by the grandmother, who asked us to give the car a really good look over since she didn’t want the granddaughter to have any problems or expenses with the gift.

Our initial inspection showed the vehicle was in good condition overall, considering that it had 180,000 miles on the odometer, and there were no issues with the suspension or brakes. We had some service records on the car so we reviewed them and then changed all the fluids and checked the filters and plugs, which looked like they had been recently replaced.

We discovered one problem that had to be addressed — a “service engine soon” lamp was illuminated. What little history we did have included a note that we had previously looked at this problem and made note of a P0011 DTC indicating a problem with the intake valve timing control – B1. We also noted that the car was a few quarts low on oil. We learned from experience that when we have a car with a variable cam timing code, the next step is to check the oil; oftentimes, you will find it is low and chances are the car is due for an oil change service.

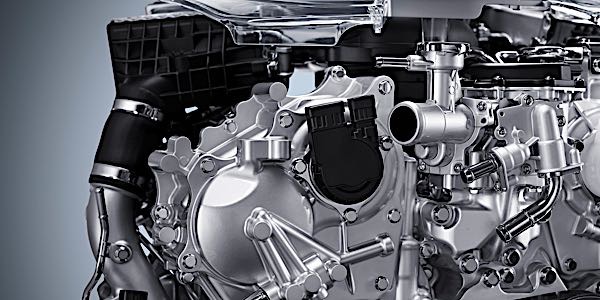

Variable cam timing has been around long enough that we should all be familiar with how it functions. In our case with this 2009 Murano, we are looking at one of the basic systems where only the intake advance is variable. Later systems control both camshafts as well as incorporate variable valve lift — giving the engineers the opportunity to have the ideal valve action for various driving conditions.

Basically speaking, this system functions when the engine control unit sends a signal to the valve timing control solenoid that controls the flow of oil to the variable cam timing gears. In turn, this oil pressure releases the lock pin in the gear while changing the relationship between the sprocket part of the gear and the camshaft, thereby changing the valve timing.

While we’re looking at the more basic system with our Murano, Nissan has continued to develop the technology. As mentioned earlier, later model vehicles incorporate the ability to advance and retard both the intake and exhaust cams as well as modify valve lift and duration. Combine this technology with variable intake tracts and you have the best performing, cleanest-running engine possible for the given conditions. There is plenty of info out there on this technology, and a quick Google search is all it takes to find it. The one thing that holds true with all of these systems is that they rely on a good, clean source of motor oil for proper operation.

Digging In

Getting back to our Murano, since our problem was so intermittent, it went weeks without setting the single trip code. Our initial thought was that there was sludge in the lubrication system. This was based on our recollection that when we first saw the code, the oil was low and the vehicle was a few thousand miles overdue for a change. We considered some of the things that are common to this problem, such as reports of the rear timing cover gasket failing near the oil port, which will lower the pressure in the system. We dismissed this cause based on the fact that we were getting the code only for Bank 1. If we had low pressure, we figured we would be getting more consistent codes for both banks.

We discussed other possibilities, such as a cam sensor that was dropping out. Although, that was not likely since our experience with Nissan tells us that if there is a problem with a cam or crank sensor, it will set a code for the offending sensor, and there was no code present for a cam sensor.

Other considerations were that the timing chain had jumped or the cam sprocket was bad. Again, we relied on the experience we gained when this system was introduced on the 1988 350Zs, and we didn’t have any of the noises that were associated with that type of failure. If it had jumped a chain, we decided the issue wouldn’t be so intermittent; in spite of the high mileage, this car ran well with good power.

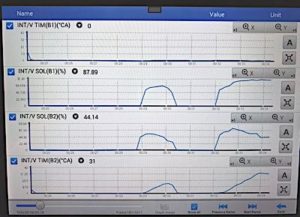

At this point, we decided to road-test the car with the scanner installed. Bringing up the data list, we chose to display the parameters that were related to camshaft control. In this case, they included the solenoid and cam timing for both banks. With this information, we were able to confirm that the chain had not jumped with both cams reporting zero degrees at idle. We initially saw no problems while on the road. After driving it with an assistant for about a half hour, I decided to drive the car on my own to see if it would set a code. With the scanner on the steering wheel, I carefully drove around on back roads looking for a glitch or failure.

Proper Tools

One of the big advantages of these newer tablet-based scanners is the length of the “movie” or record modes. With the scanner set up in graphing mode, I thought I caught a glimpse of the Bank 1 solenoid being commanded on with no change in the Bank 1 cam timing. Knowing that I probably caught the event on the recording, it was back to the shop for the tedious challenge of trying to find it on the recording. By carefully reviewing the recording, we were able to confirm the solenoid command versus a solenoid reaction.

Now we knew what was happening, but we still weren’t sure if the problem was the solenoid, sludge or the cam gear. The scanner told us that the solenoid was instructed to operate, but we don’t really know if it reacted to the command. We decided to remove the solenoid to check for smooth operation and any signs of sludge. The access to the solenoid is not great, so it is best to get to it from under the car. Remove the bracket holding the wiring harness in place. There is one bolt that retains the solenoid, but it can’t be removed without removing one of the cover bolts that prevents the solenoid from sliding out.

There was no sign of sludge, as the solenoid was very clean. We repeatedly tested the solenoid on the bench by applying power and ground. Note: When performing this test, don’t let the solenoid overheat; just flash the power to the connector looking for the solenoid to open.

Next, we cleaned the solenoid and blew it out with compressed air while we operated it to remove any debris.

As the tech and I talked things over, we decided to replace the solenoid, even though we couldn’t confirm it was a problem. We made this decision based on what we knew and what we found looking at some of the online forums. What we knew was the system was being commanded to work, and it did work 99% of the time. It passed the bench test, but with it being so intermittent, we weren’t sure we would have caught it the one time it didn’t function.

The online forums are a good source of information, but they certainly don’t replace a good diagnosis. We’ll use them to get confirmation on what we already know, and it never hurts to take advantage of someone else’s experience. For example, if you have eight techs post that they have seen intermittent solenoids, it gives you a bit more confidence to just replace the part. But, I’m never really comfortable going that route. It is always a gamble when you explain the situation to the customer, saying that even though you’re not really sure of the diagnosis, you’re now pretty much guaranteeing that it is fixed with a new part.

With the new solenoid installed, the car was delivered to the granddaughter, and so far, there are no issues. The light hasn’t reset and she is enjoying granddad’s gift. Looks like a win-win for everyone involved.