Courtesy of SKF

When identifying timing belt, tensioner and idler failure, the first sign of wear is noise. For example, if the tensioner sounds bad, it’s usually bad.

Start by listening to hear if any noise is coming from the timing cover or front assembly while the engine is running. Bad bearings make a high pitched “whine” or “growling” noise after the engine has been started. If there is noise, and it is identified as coming from behind the timing cover, follow these steps:

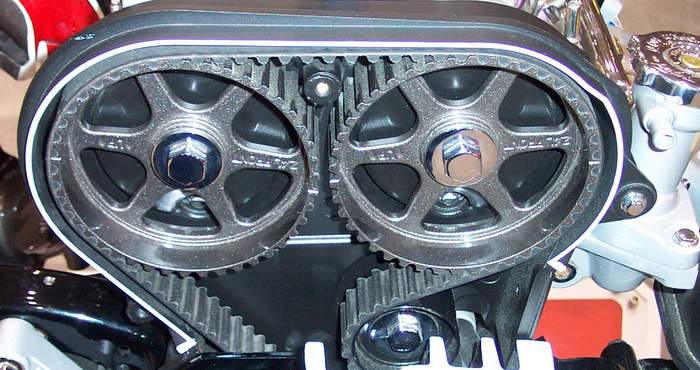

• Remove the timing belt cover(s) and inspect the timing belt.

• Misalignment of the timing belt can cause premature failure of the idler pulley on the tensioner as well as the belt. Generally, this indicates that the tensioner or idler is not correctly attached to the mounting location on the engine, or the bearings for the tensioner, idler or both have worn out and have excess play. Correcting belt and bearing alignment is critical.

• With the timing belt removed, check the idler pulley(s) for failure.

• Check for side-to-side play or rocking on both the idler pulley and tensioner pulley. Replace if any movement is detected.

• Check both the idler and tensioner pulleys for roughness when rotating the bearing. The idler and tensioner should spin freely and smoothly. Replace the bearing(s) if roughness is determined.

• Do not re-use the timing belt, tensioner or idler if misalignment is found. Replace with new components to avoid engine damage or failure.

SKF recommends replacing timing belts, tensioner and idlers at 60,000 to 80,000 miles to prevent unnecessary engine damage.

Courtesy of SKF. For more information about SKF, contact your local SKF representative, visit www.vsm.skf.com, or call 800-882-0008.