Timing Chain Replacement is More Than Just the Chain

Timing chains, with their thinner width, reduce overall engine length and are more durable than timing belts, requiring no scheduled maintenance. Timing chains do make more noise, have higher weight and higher cost than timing belts, though. Replacement timing chain kits can cost hundreds more than replacement timing belts, especially on OHC engines. This makes rebuilds of chained OHC engines very expensive.

However, over the past 20 years, belt applications have been fading out. The Achilles heel of belts has always been the recommended change interval, which, for the most part, remains around 60,000 miles. A timing belt is considered an internal engine component, mission critical, and most manufacturers offer powertrain warranties of 100,000 miles — they do not want a mission critical component that can’t make it through the warranty period.

Often maintenance neglect, head gasket replacement or related valvetrain issues will require the timing chain to be serviced. If you are replacing the timing chain, you need to look at all the related components.

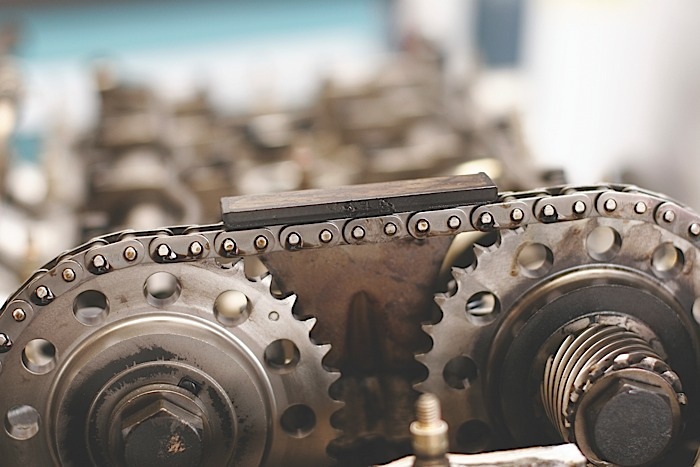

Guides

The chain guides are often the best indicators of the health of the timing chain. Wild wear patterns would indicate a chain system problem. Most systems are engineered to keep the timing chain under control while the chain wears, but if those limits are exceeded, problems will show.

Guides can show if the owner has kept up with oil and filter changes. If the oil becomes acidic, the softer materials of the guides can be destroyed. If the oil change is avoided and the filter goes into bypass because it is clogged, the metallic particles will accelerate wear even faster. It you are replacing the timing chain, it is always a good practice to replace the guides.

Tensioners

The majority of timing chain tensioners use oil pressure to take up slack in the chain. Like the guides, a tensioner will age prematurely as old oil degrades the seals and clogs the oil passages.

The typical tensioner assembly consists of a housing, spring and ratcheting plunger. The plunger is locked into the housing to prevent the accidental release of the spring before or during installation.

Gears

Historically, sprockets have been aluminum or cast iron while crank gears have been steel or powdered metal. But now, many new engines have cam sprockets and crank gears that are both made of powdered metal. The OEMs say powdered metal is as durable as steel and is lighter and easier (cheaper) to manufacture.

Another change in some engines today is magnetic timing sensors on the cam sprocket. A magnet mounted on an aluminum cam sprocket passes under a pickup coil that generates a signal to the engine computer. This keeps the computer informed about the firing order of the engine so it can control ignition timing, and in some cases, sequential fuel injection pulses accordingly. The OEMs recommend only aluminum replacement sprockets be used in such applications.

Variable Valve Timing Actuators

Other items to be inspected are the camshaft actuators on valvetrains with variable valve timing. These components can suffer like guides and tensioners due to infrequent oil changes. If the actuators are ignored, it could result in codes for camshaft and crank sensors. Also, misfire codes could be set if the actuators are ignored.