Affected Vehicles: 2003-’06 Sorento (BL) 3.5L, 2002-’05 Sedona (GQ) 3.5L, 2001-’06 Optima (MS) 2.4L and 2004-’06Amanti (GH) 3.5L models

Affected Vehicles: 2003-’06 Sorento (BL) 3.5L, 2002-’05 Sedona (GQ) 3.5L, 2001-’06 Optima (MS) 2.4L and 2004-’06Amanti (GH) 3.5L models

Information About DTC P1330

In affected vehicles, an intermittent short to ground in a circuit only intended for testing purposes may cause the MIL to illuminate and a DTC P1330 (Spark Timing Adjust) to be stored. As soon as the fault disappears, the MIL may turn off and the fault code can also be immediately erased by the engine management system, making it hard to diagnose the concern.

DTC P1330 is intended to be triggered when specific terminals in the multi-purpose data link/check connector are grounded. When these terminals are grounded, a default control mode is temporarily activated in which the spark timing is fixed.

This function is intended to only be used during certain checks on the vehicle assembly line. To ensure that vehicles do not leave the assembly plant in this (spark timing fixed) condition a P1330 DTC will set and illuminate the MIL whenever this function is active.

However, reports from in-use vehicles have indicated that the same condition can occur when these terminals and/or associated wiring are shorted to ground as a result of an electrical fault, thus setting the P1330 code and illuminating the MIL.

However, reports from in-use vehicles have indicated that the same condition can occur when these terminals and/or associated wiring are shorted to ground as a result of an electrical fault, thus setting the P1330 code and illuminating the MIL.

When diagnosing a complaint of (intermittent) MIL illumination with no DTCs present, first check for freeze-frame data. If the cause was due to a fault detected by the DTC P1330 logic, freeze-frame data should still be available and indicate that P1330 was the DTC that caused the freeze-frame data to be stored.

To diagnose and repair a P1330 fault, inspect related connectors or wiring harness and repair as necessary following the instructions in this bulletin.

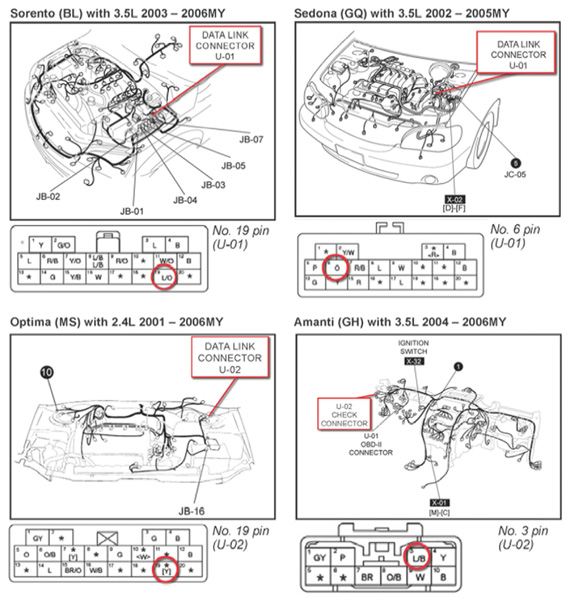

Data Link/Check Connector Terminal and Connector Inspection

1. Turn off the ignition.

2. Thoroughly check the connector terminals for corrosion bending, contamination, deterioration or damage. If any problem is found, repair or replace the connector. See Figure 1.

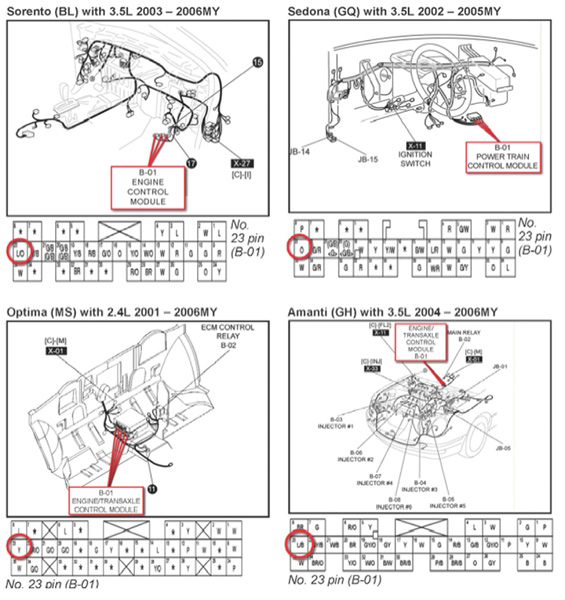

Control Module Wiring Harness Inspection:

1. Disconnect the engine control module connector (or powertrain control module or engine/transaxle control module connector) as indicated in Figure 2.

2. Measure the resistance between the identified terminal of data link/check connector and chassis ground and between the identified terminal of the wiring harness side of each control module and chassis ground.

3. If the measured resistance is below 1,000 ohms, the harness is shorted to ground. Repair or replace the harness or additional connectors in the circuit as necessary.

4. Apply dielectric grease before reconnecting.

Verification After Repair

1. Turn on the ignition.

2. Using the Kia GDS scan tool, clear DTC(s) and freeze-frame data.

3. Start the vehicle and let idle for 2 to 3 minutes.

4. Check the MIL and DTC/freeze-frame data once again. Make sure MIL is not illuminated and that the P1330 DTC and associated freeze-frame data are not stored.

Courtesy of ALLDATA.