end of the shaft, in a separate housing, is another wheel with angled blades known as the compressor wheel.

Just like the turbine housing in which the exhaust gas spins the wheel, the compressor housing has an opening to take in fresh air from the air filter as the compressor wheel spins from being connected to the turbine wheel. The fresh incoming air is compressed and forced out of an opening in the compressor wheel housing.

From there the compressed air travels into an intercooler (if equipped) and into the intake manifold. As engine speed increases, the turbine and compressor wheel speed also increases. This forces more compressed air into the intake manifold, which causes a pressure rise, what we refer to as “boost.”

Turbo Upgrade

In the aftermarket, there are so many upgrades for turbos, especially on the mid-size diesel trucks. How do you determine which one is right for your application? One thing that is always a concern is boost, because people associate boost with power.

While this may be true, determining the right turbo goes beyond how much boost you want to run. The first step is to find out how much horsepower you want to produce and make sure this is a realistic figure for the application. In street applications a smaller turbo works best because of its excellent response time, while in racing applications a larger turbo is needed because response time is not as much of a concern. The main concern in racing is optimum power at optimum engine speed. For street applications you’re usually looking for the best all-around performance at various engine speeds.

When choosing to upgrade the turbo, we often leave this decision to the turbo manufacturer for our application. This is a good thing because the manufacturers have spent many hours and resources on developing their turbos, especially on production vehicles.

When choosing to upgrade the turbo, we often leave this decision to the turbo manufacturer for our application. This is a good thing because the manufacturers have spent many hours and resources on developing their turbos, especially on production vehicles.

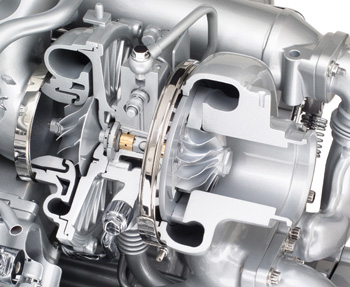

However, leaving the designs to the experts doesn’t mean you can’t learn more about what is going on inside the turbo and its effect in producing power (see Figure 1).

First, let’s consider the term “trim.” Trim refers to an area ratio between the turbine and compressor wheels. Since the blades of each wheel are spiral and fan shaped they have two diameters. These two diameters are known as the inducer and exducer. The inducer diameter is where the air enters the wheel, while the exducer diameter is where the air exits the wheel. However, pay attention because this is where it gets tricky!

On the exhaust side in the turbine housing, the inducer is the larger diameter of the turbine blade. This is where exhaust gas is entering the turbine housing. On the compressor wheel the inducer is the smaller diameter of the compressor blade, because this is where filtered outside air enters the compressor housing. On the turbine blade the smaller diameter is the exducer, where the exhaust exits the turbine housing into the exhaust pipe. On the compressor wheel the larger diameter of the blade is the exducer where compressed air exits into the compressor housing to the intake manifold.

This is the formula:

TRIM = [Inducer2] x 100

[Exducer2]

= 55mm x 55mm x 100

75mm x 75mm

= 3025 x 100

5625

TRIM = 54

Turbo Calculations

Here’s an example: Let’s say you have a compressor wheel with an inducer diameter of 55 mm and an exducer diameter of 75 mm. Using the formula above, what is the trim of the compressor wheel?

Whether it is the compressor or turbine wheel, the trim can affect performance by shifting the airflow capacity. A higher trim wheel ratio will, in turn, flow more than a lower one, but other factors will influence this, so bigger isn’t always better.

Turbo Area

Turbo Area

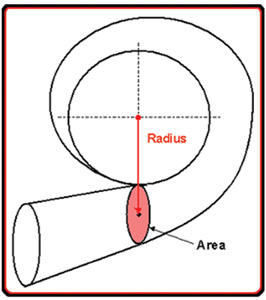

Next is the term known as A/R (Area/Radius). You can actually see this sometimes stamped on the manufacturer’s compressor housing. This is the equation that makes up the geometric shape of the compressor and turbine housings: it is the inlet cross-sectional area divided by the radius from the turbo centerline to the center of that area. It sounds confusing, I know, but Figure 2 provides a better look.

Changing the A/R in the compressor housing really doesn’t affect turbo performance and most manufacturers don’t offer A/R options for the compressor housings, anyway.

The turbine housing, on the other hand, is a different story. This is used to adjust the flow capacity of the turbine, which is what drives the turbine wheel to spin. A turbo with a larger A/R will have a slower rise in boost and operate at higher engine speeds while a lower A/R will have quicker boost rise but suffer from increased backpressure and not operate efficiently at higher engine speeds.

Looking at A/R numbers you can usually see what the intended purpose is. If you have a turbo on your diesel with an A/R of 0.7, you can see that it was meant for great quick boost and street driving compared to if you installed a turbo with an A/R of 1.1.

In today’s light-duty and mid-size diesel trucks, you may see a technology known as VGT, variable geometric turbo. This design allows the angle of the blades to change with engine speed. Manufacturers take the oil pressure used to lubricate the turbo and divert it to a solenoid mounted on the side of the turbo. The solenoid is controlled by the PCM. As engine speed rises, the PCM will command the solenoid to open at a desired rate to change the geometry of the compressor blades.

This is used to operate from no boost at idle to full boost at WOT. Manufacturers use this to help eliminate turbo lag and be more efficient. This way, the compressor wheel in the turbo is not a fixed unit, and can change as the demand for boost changes.

Whether it has been used in normal or in towing applications, drivers should remember to let the engine cool down a little before shutting it down. When a hot turbo is simply shut off, heat soak begins. The heat from the head and the exhaust housing migrates to the center of the turbo. This is where the bearings are and this is the reason the turbo is fed with pressurized engine oil. A hot shut-down can result in oil coking which, in turn, will damage the bearings of the turbo and can result in severe engine damage.

Many people who own diesels don’t realize the effects of hot shut-down, especially when compared to a gasoline engine. One thing that turbo manufacturers have done to combat this problem is to use coolant from the radiator. So not only do you have oil to cool the bearings, but also coolant from the radiator. So the coolant circulates to also help take the heat away in case the person who owns the diesel does not let it cool down.

Some aftermarket companies offer what is called a “turbo timer” that allows a driver to the ignition off, remove the key and lock the doors. The “turbo timer” will continue to let the engine run until the desired exhaust temperature is reached. At this time the engine will shut down and everything will return to normal.

Robert McDonald is owner of Atlantic Engines in Granite Falls, NC, and specializes in high performance diesel and gasoline engines and cylinder heads for street, marine, dirt and drag racing.