1989 — Smaller 3300 (3.3L) spin-off of the 3800 introduced.

1990 — The intake system was upgraded to Tuned Port Injection for more horsepower and torque. Also, a one-piece rear crankshaft oil seal was offered in some 3800 engines to reduce oil leaks.

1991 — L67 supercharged version of the 3800 appears. An Eaton blower boosts horsepower to 205.

1993 — The 3800 V6 got roller rocker arms, a higher compression ratio, and another reduction in piston ring tension to improve fuel economy and performance.

1994 — Supercharged engine gets larger blower pulley and larger throttle to make more horsepower (225 hp).

1995 — Series II 3800 introduced with revised, lighter block, cross-bolt main bearing caps, lighter pistons, a higher compression ratio (9.4:1)and shorter steel rods. It also had improved cylinder heads with bigger valves, a composite plastic intake manifold, revised accessory mountings on the engine, dual knock sensors, improved oil seals and a plastic engine cover to muffle noise.

1996 — Supercharged Series II 3800 gets a bigger supercharger for more boost and power (240 hp).

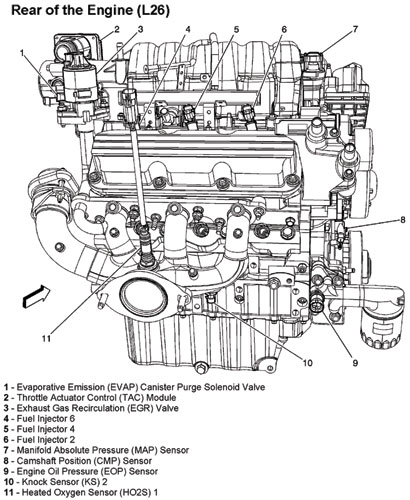

2004 — Series III L26 3800 V6 introduced, with electronic throttle control, returnless fuel injection, stronger powder metal connecting rods, and an aluminum upper intake manifold to replace the troublesome plastic intake manifold. Applications include the 2004-’08 Pontiac Grand Prix, 2005-’08 Buick LaCrosse and 2006-’08 Buick Lucerne. An L32 Supercharged Series III 3800 also is introduced, rated at 260 hp in the Pontiac Grand Prix GT and GTP.

2008 — End of the road for the 3800. Production will cease this year, with the 3800 being retired to the big boneyard in the sky. The engine will be replaced with the naturally aspirated LZ4 3500 OHV V6, or the LY7 3600 DOHC V6 in vehicles that used the supercharged 3800.

Service Issues

One of the reasons why the 3800 has had such a long production run is that it has been a very reliable, trouble-free engine for the most part. Many of these engines have racked up well over 200,000 miles with normal maintenance.

One of the few trouble spots has been coolant leaks on the Series II 3800 engines with the plastic intake manifold. The OEM intake manifold gasket tends to deteriorate after 60,000 or so miles in the area that seals the cylinder head coolant passage to the manifold. The seepage of coolant past the leaky gasket leads to overheating, and may cause bearing damage if coolant leaks down into the lifter valley and gets into the crankcase. The fix is to replace the OEM gasket with an improved aftermarket gasket, or the revised OEM gasket (P/N 89017554) per GM bulletin 04-06-01-017 issued in May, 2004.

The coolant leakage problem has been blamed on a number of factors, including coolant neglect and a less-than-robust OEM intake manifold gasket design. Though Dex-Cool is supposed to last up to five years or 150,000 miles, some say changing the coolant every two years can avert many of the problems that occur with aging coolant. Also, if the coolant level gets low, oxygen mixes with the coolant, which tends to cause problems with Dex-Cool.

On these engines, it’s not a bad idea to add a bottle of cooling system sealer to the cooling system for preventive maintenance, whether the coolant needs changing or not. The sealer will circulate with the coolant and hopefully stop any small seepage leaks in the intake manifold gasket from getting any worse, at least for a while. This may save your customer the expense of having to replace the intake manifold gasket. If the gasket is already leaking, sealer may plug it up temporarily. But, eventually, the gasket will have to be changed.

Another coolant leak problem prompted GM to issue a recall on certain 2000-’03 model year Chevys, Buicks and Pontiacs with the 3800 engine. The coolant leak on these engines was at the gasket between the intake manifold and throttle body or, in some cases, between the upper and lower intake manifold. The recall involved replacing the three throttle body fasteners, applying sealer to the threads, and dumping some sealer pellets into the cooling system reservoir. Recall 03034 was issued in July, 2003, but was only good until July, 2004. If a vehicle was repaired under this recall, there should be a GM recall decal affixed to the engine or under the hood.

Ignition System

Ignition System

The distributorless ignition system has also been fairly reliable, with some occasional crankshaft position sensor or coil failures. The 3800 engine has a “waste spark” distributorless ignition system with three ignition coils, (see photo above, right) an ignition control module, a dual Hall-effect crankshaft position sensor and an engine crankshaft balancer with interrupter rings attached to the rear. The PCM controls spark timing.

Each coil fires two cylinders with cylinders 1/4, 2/5 and 3/6 each sharing a coil. Since the polarity of the ignition coil primary and secondary windings is fixed, one spark plug always fires with normal polarity while its companion plug fires with reverse polarity. Because the ignition coil requires approximately 30% more voltage to fire a spark plug with reverse polarity, the ignition coil  requires more saturation time (loner dwell) and a higher primary current. This allows the coils to produce up to 40Kv if needed.

requires more saturation time (loner dwell) and a higher primary current. This allows the coils to produce up to 40Kv if needed.

If you have a 3800 that cranks but won’t start because there is no spark, check to make sure the coils have voltage when the key is on. If there is no trigger signal from the crankshaft position sensor, the PCM won’t fire the coils and there will be no spark.

The coil pack on these engines runs hot, so it’s important to make sure there is heat sink grease under the coil to transfer heat. If the coil module gets too hot, it will fail.

If an engine is hard to start or has a misfire at higher speeds, the problem may be a weak coil, a bad plug wire, or a fouled or worn spark plug. On 1996 and newer vehicles, you should get a cylinder misfire code. A code for one cylinder would likely indicate a fouled plug, bad plug wire, or possibly a clogged or dead fuel injector, or a compression leak (burned exhaust valve). Misfire codes for two cylinders that share a coil would likely point to a bad coil.

Another way to figure out if a misfire is a bad coil is to swap two of the coils on the coil pack. If the misfire moves to the new cylinders, the problem is the coil. If the misfire remains in the same cylinders, the coil is OK and the problem is the wires, plugs, injectors or compression.

If you test a coil with an ohmmeter, the test specs are 0.5 to 0.9 ohms for the primary terminals under the coil, and secondary resistance of 5,000 to 8,000 ohms at the high-voltage terminal.