The GM 3800 Series II engine, introduced in 1995, is quite a different engine from its predecessor, the Series I engine. While the stroke for the 3.8L engine remained at 3.4” (86 mm), and the bore remained at 3.8” (97 mm), the engine architecture changed dramatically.

The deck height is shorter than the Series I, which reduced its weight and total engine package size. To make this change, GM engineers required that the piston connecting rods be shortened 1” (25 mm), and to redesign the crankshaft. A new intake manifold improved breathing, while a redesigned cylinder head featured larger valves and a higher compression ratio. The result was a 205 hp and 230 lb.-ft. powerplant that had better fuel economy.

To meet emissions standards of the ’90s, an EGR tube was placed in the intake manifold to reduce combustion temperatures. This increased fuel mileage by a substantial margin and provided GM some engineering success. In fact, the 3800 Series II was on the Ward’s 10 Best Engines list 1995 through ’97.

However, in April, 2009, GM issued a recall on 1.5 million vehicles with this engine due to an oil leak issue that could result in a fire. (See the sidebar at the end of this article).

Did You Know…

Did You Know…

The Buick 3.8L has evolved from its humble beginnings as a cheap, easy-to-build, economy motor in 1962, into one of the best pushrod motors in the world.

But did you know that the engine started its “life” as a Buick V8 that had two cylinders “missing”? That was to allow GM to machine it on the same line as their V8 with common tooling. Unfortunately, that meant it had two cylinders missing in the firing order — making it a strange-sounding, rough-riding, odd-firing engine.

While that was fine for the 1960s, it wasn’t good enough in the ’70s and in 1977, Buick split the crank pins to make it into an even-fire motor with smother performance.

Unfortunately, the engine still had a severe primary imbalance because it was a 90° block with a 120° firing order. GM engineers realized that the 3800 would still need a balance shaft to make it suitable for the upscale FWD cars later on. As the engine evolved into the Series I, a gerotor oil pump and roller lifters were added in ’86, on-center bores were added in ’88 along with the balance shaft, and a one-piece rear seal was introduced in ’90.

The 3800 was completely updated in ’95 when it became the Series II motor that was lower, lighter, smoother and more powerful than any of its earlier variations.

Amazingly, it’s been installed in more than 6 million vehicles since 1995. Production of the renowned 3800 V6 engine was officially ended in August 2008, nearly 10 years beyond the automaker’s original plan to cease 3800 engine production in 1999.

That’s quite a tribute to any pushrod motor, let alone one that started in life as a rough-running, odd-firing V6 in the ’60s.

Source: GM media and Engine Builder magazine

Regardless of the recent recall, the 3800 Series II has been a workhorse for GM and has provided years of dependable service. Because of its longevity and use in various GM vehicles, it’s probably an engine that you have become accustomed to seeing in your shop for routine service.

The following are a few common service repairs for the Series II engine.

Abnormal Engine Coolant Consumption or Coolant Leak

Models: 1995-’97 Buick Riviera; 1995-’99 Buick LeSabre, Park Avenue; 1996-’99 Buick Regal; 1998-’99 Chevrolet Lumina, Monte Carlo; 1995-’96 Oldsmobile Ninety-Eight; 1995-’99 Oldsmobile Eighty-Eight; 1998-’99 Oldsmobile Intrigue; 1995-’99 Pontiac Bonneville; and 1997-’99 Pontiac Grand Prix with the 3.8L engine.

Note: This bulletin, issued in September 2007, is being revised to add to the 1999 model year. You should discard the previous GM Corporate Bulletin Number 01-06-01-007B (Section 06 – Engine).

Condition: Some customers may comment on excessive engine coolant consumption, or an engine coolant leak near or under the throttle body area of the upper intake manifold.

This could be related to upper intake manifold composite material that may degrade around the EGR stove pipe and could result in an internal or external coolant leak.

To make the repair, follow the upper intake manifold removal instructions found in the Engine Unit Repair section of the service information manual.

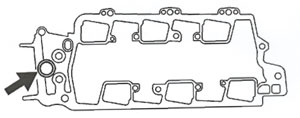

Refer to the arrow in the illustration of the upper intake manifold (see Figure 1).

Inspect the inner diameter of the EGR passage for signs of material degradation. Degradation will appear as “pitting” of the composite material in the EGR port passage.

If degradation of upper intake manifold composite material is found, replace the lower and upper intake manifolds with the following part numbers:

Part Number Description

89017554 Gasket Kit, Upper Intake Manifold

89017272 Manifold Kit, Upper Intake

89017400 Gasket, Lower Intake Manifold

24508923 Manifold, Lower Intake

Follow the lower and upper intake manifold installation instructions found in the Engine Unit Repair section of the appropriate service manual.

If degradation is not apparent, evaluate the vehicle for other causes of excessive coolant consumption as noted in the Engine Diagnosis section of the appropriate service manual.

Revised Crankshaft Balancer Service Procedure

Next up, you may have an engine that requires service to the crankshaft balancer on the following vehicles: 1995-’96 Buick LeSabre, Park Avenue, Regal, Riviera; 1995 Chevrolet Lumina APV; 1995-’96 Chevrolet Camaro; 1995 Oldsmobile Silhouette; 1995-’96 Oldsmobile Eighty-Eight, Ninety-Eight; 1995 Pontiac Trans Sport; 1995-’96 Pontiac Bonneville and Firebird with 3800 engines.

Be advised that the procedure used to service the crankshaft balancer has been revised. Use the following procedure to properly service the crankshaft balancer on these engines.

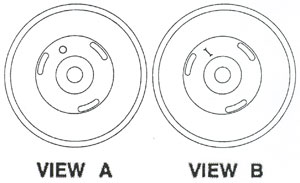

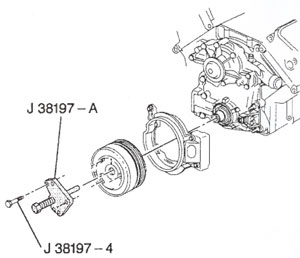

According to GM, there has been a running design change in the crankshaft balancer. This change affects 3800 engines built late in the 1995 model year (L27 and L36) and all of 1996 model year (L36 and L67). Refer to the appropriate section in the service manual if you have the previous design crankshaft balancer. Refer to the following procedure using (J 38197-MOD) for the revised design crankshaft balancer. The crankshaft balancer designs can be easily identified by a dimple stamped in the face of the crankshaft balancer (see Figure 2, view B).

This dimple aids in the alignment of J 38197-2 and also identifies the crankshaft key location in relation to the slot in the crankshaft balancer. The special tool (J 38197) and the service procedure used to service the previous design crankshaft balancer have not been revised. Refer to applicable service manual and section for correct service procedures.

For the revised crankshaft balancer design, you will see a round hole drilled in the face of the crankshaft balancer (see Figure 2, view A). This hole does not aid in the alignment of J 38197-2, like the dimple on the previous designed crankshaft balancer. The hole is used to identify the crankshaft key location in relation to the slot in the crankshaft balancer.

The special tool (J 38197) has been revised to reflect the design changes and the new tool is

J 38197-MOD. (If you already have J 38197, it is necessary to only order the J 38197-MOD). The revised crankshaft balancer requires the use of three bolts (J 38197-4). Note: These bolts are 1/4” longer than the previous design. The J 38197-4 bolts are silver, while the previous tool uses black bolts.

Note: The J 38197-4 tool should not be used to service the previous design crankshaft balancer as damage to the balancer may occur by using the longer bolts.

The revised crankshaft balancer may have burrs on the slotted access holes that do not allow the proper alignment of J 38197. If burrs are present, remove them by using one of the following methods:

• File the access hole using a rat-tail file in the proper location.

• Drill an access hole using a drill in the proper location.

• Bend the access hole using a screwdriver in the proper location.

Removal Procedure

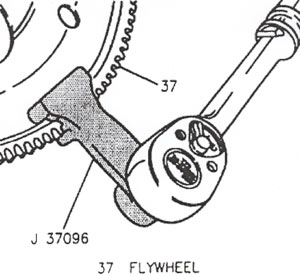

1. Hold the flywheel using J 37096 (see Figure 3).

2. Locate the crankshaft balancer bolt.

3. Remove the crankshaft balancer using J 38197-A and J 38197-MOD (see Figure 4 on page 30).

a. Invert the J 38197-2 so that the leg of the tool is facing away from the crankshaft balancer.

b. Install the silver screws (J 38197-4) to the crankshaft balancer.

c. Turn the J 38197-1 to remove the crankshaft balancer from the crankshaft.

d. Remove the J 38197-1, 2 and 4 from the crankshaft balancer.

Important: The crankshaft balancer is serviced as an assembly. Do not attempt to separate the pulley from the balancer hub.

Tools Required

J 36660 Torque Angle Meter

J 37096 Flywheel Holding Tool

J 38197-A and J 38197-MOD Crankshaft Balancer Puller

J 38197-A Includes:

J 38197-1 Pilot Screw

J 38197-2 Puller Plate

J 38197-3 Puller Screws (Black)

J 38197-4 Puller Screws (Silver)

J 38197-MOD includes:

J 38197-4 Puller Screws (Silver)

Installation Procedure

1. First, lubricate the crankshaft and the inside of the balancer with clean engine oil.

2. Lineup the crankshaft balancer using the small hole to aid in the alignment of the crankshaft key.

3. Install the crankshaft balancer bolt and hold the flywheel using

J 37096.

4. Tighten the bolt to 150 Nm (111 lb.-ft.) + 76° using J 36660.

Source: ALLDATA

General Motors Issues Recall on 3800 V6 Powered Vehicles

General Motors is recalling nearly 1.5 million 1997-2003 vehicles equipped with the 3.8L V6 naturally aspirated engine.

Affected vehicles include: 1997-2003 Buick Regal; 2000-’03 Chevrolet Impala; 1998-’99 Chevrolet Lumina; 1998-2003 Chevrolet Monte Carlo; 1998-’99 Oldsmobile Intrigue and 1997-2003 Pontiac Grand Prix.

GM said some of these vehicles have a condition in which drops of engine oil may be deposited on the exhaust manifold through hard braking. If the manifold is hot enough and the oil runs below the heat shield, it may ignite into a small flame and may spread to the plastic spark plug wire channel and beyond, increasing the risk of an engine compartment fire.

GM said dealers will remove the spark plug wire retention channel at the front of engine and install two new spark plug wire retainers free of charge. The recall is expected to begin this month and owners and technicians can contact Chevrolet at 1-800-630-2438, Oldsmobile at 1-800-630-6537, and Pontiac at 1-800-620-7668.

Source: General Motors