This article will document the infamous P0456 code — 0.20 leak detected. A small leak code can be the most challenging for any of us, so the following is a suggested plan of attack.

Through my research, I’ve found that all of the auto manufacturers appear to run their EVAP monitors in a certain sequence, and I have studied this in detail for GM, Ford and Chrysler vehicles.

We’ll begin our diagnostic journey with Chrysler. There is a manual that Chrysler produced some time ago that offers an engineering perspective into the operation of its Leak Detection Pump (LDP) system — Leak Detection Pump Operation and Diagnosis (Publication No. 81-170-00006). (It can be purchased off of the Chrysler website if you’re interested in reviewing it, or you can contact me at  [email protected] and I will provide additional information on it.)

[email protected] and I will provide additional information on it.)

Upon review of the manual, it shows that when the system is under test, it begins with a P1495 or P1496 check. This is a check to see if feed voltage applied (>10.4 volts) to the LDP has made its way back to the PCM to be grounded for pump operation. This is done at KOEO.

The second check is a P1494. This is done on startup and the LDP solenoid is energized to see if it’s able to operate on command. Note: Make sure that there is a good vacuum source to the pump so that false codes are not set.

The third check, P1486, is a blockage test for the system. If the system passes this series of checks, the system has passed all electrical and mechanical testing for the system per the PCM.

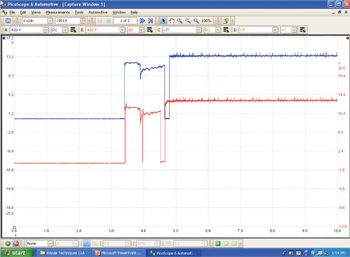

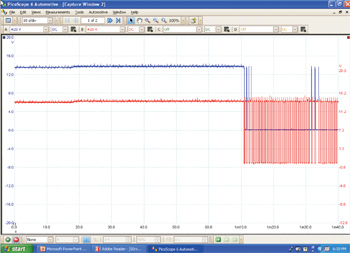

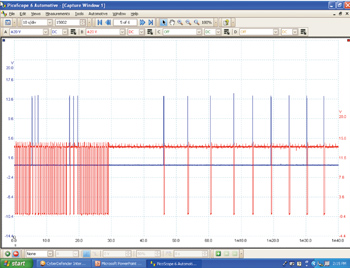

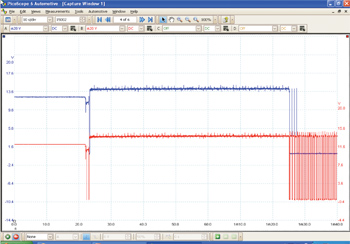

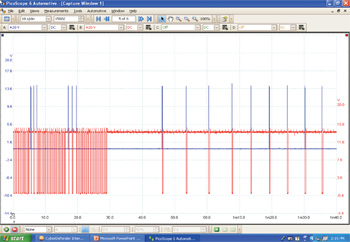

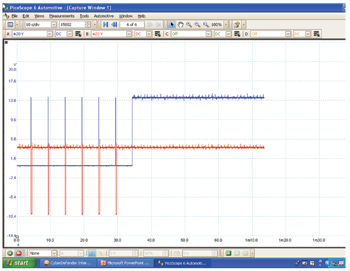

The series of waveforms in Figures 1 through 7 show the beginning portions of the test via a lab scope.  The blue pattern is the LDP switch and the red pattern is the LDP solenoid. These serve as known-good patterns.

The blue pattern is the LDP switch and the red pattern is the LDP solenoid. These serve as known-good patterns.

The next test in line is called “Pump Mode.” This is the time period for which the pump will be used to pressurize the system, and, per Chrysler, no codes will be set during this time period. Once the Pump Mode is complete, the system will then begin what is called “test mode” or “pump period.”

The EVAP system has now reached a point in its sequence where leaks can be tested. The size of the leak is based on when the purge solenoid stopped and how long the LDP switch remained in the open position. This time element was determined by Chrysler. Here are the time periods:

— Less than 0.9 seconds equals a gross leak

— Between 0.9 to 1.2 seconds equals a medium leak

— Between 1.2 to 6 seconds equals a small leak

We now begin our story with a 2003 Dodge Caravan with a 3.3L engine. The EVAP system has set a code P0456 indicating that a small leak may be present. Note: It is always advisable to check for TSBs and any preliminary service information that may be available on the vehicle you are working on. This could save valuable diagnostic time.

A TSB check does indeed yield a bulletin: MIL Illumination, Erroneous DTC P0456 — EVAP Leak Monitor 0.020 Leak Detected. The fix per this bulletin is a new PCM. The PCM part number is not in the range indicated on this bulletin, so we will proceed with our diagnosis.

We start by forcing the monitor to run with a DRB III scan tool.

The activity is monitored with a lab scope to aid in the learning process. The following screens denote the process as witnessed:

A failure has now been confirmed; a code P0456 is stored in the controller’s memory.

A smoke test is done on the system and no smoke can be seen coming from the vehicle. We use a smoke machine with a flow meter to confirm the diagnosis.

The EVAP system is then isolated from the tank and retested, but the leak is not present.

Next, we test the fuel tank as a standalone unit. See Figures 8 and 9.

The leak has been found!

A less-than-impressive repair to the gas tank was the cause of our leak. This Pulling Code case is now closed.