If pressure is low and amperage is above specification, check:

If pressure is low and amperage is above specification, check: If pressure is low and amperage is above specification, check:

If pressure is low and amperage is above specification, check: If pressure is low and amperage is above specification, check:

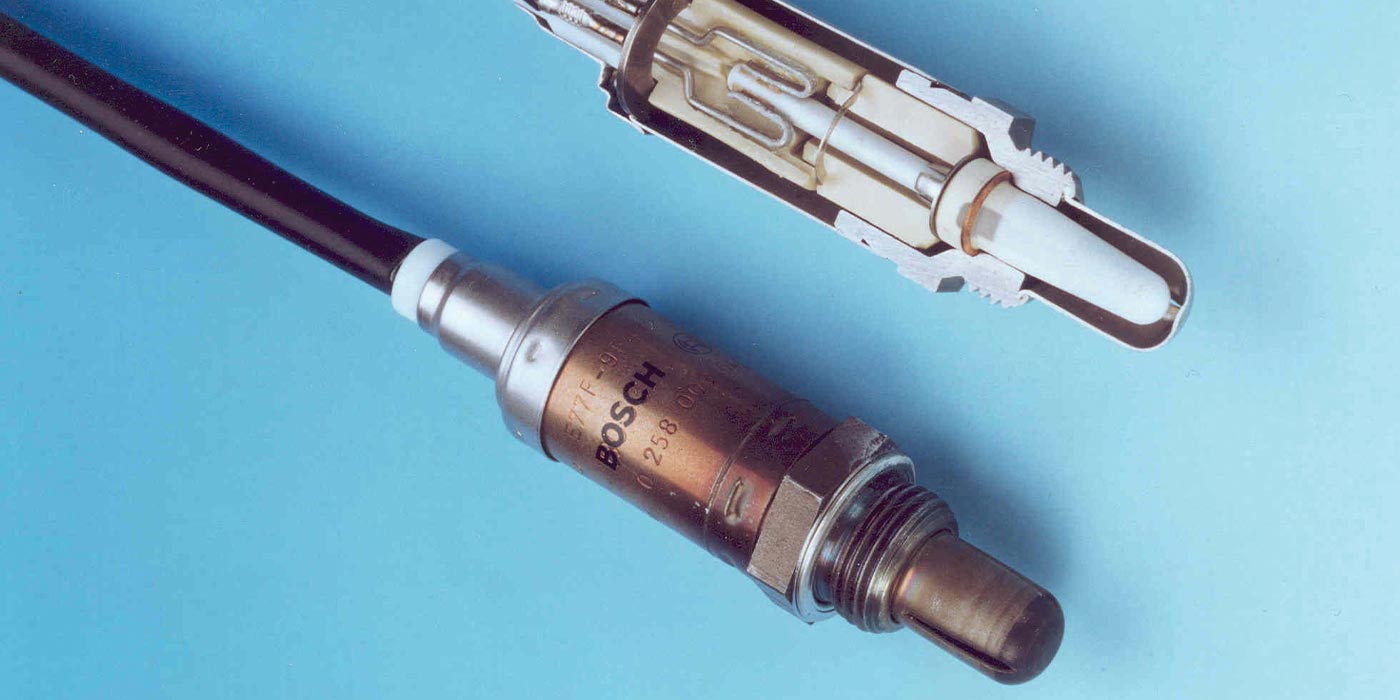

If pressure is low and amperage is above specification, check:When oxygen sensors are tested, manufacturers will introduce small amounts of oil to measure sensitivity.

An engine management system is always trying to find the perfect air/fuel ratio. But it is next to impossible to walk the line between too rich or too lean. With every revolution of the crankshaft, small changes in the air, fuel and operating conditions can cause changes to the oxygen content coming out of the exhaust port.

One of the problems with ethanol is how it reacts to water in the air and in the tank.

If an O2 sensor is not reading properly or is borderline, it should be replaced regardless of its age or mileage.

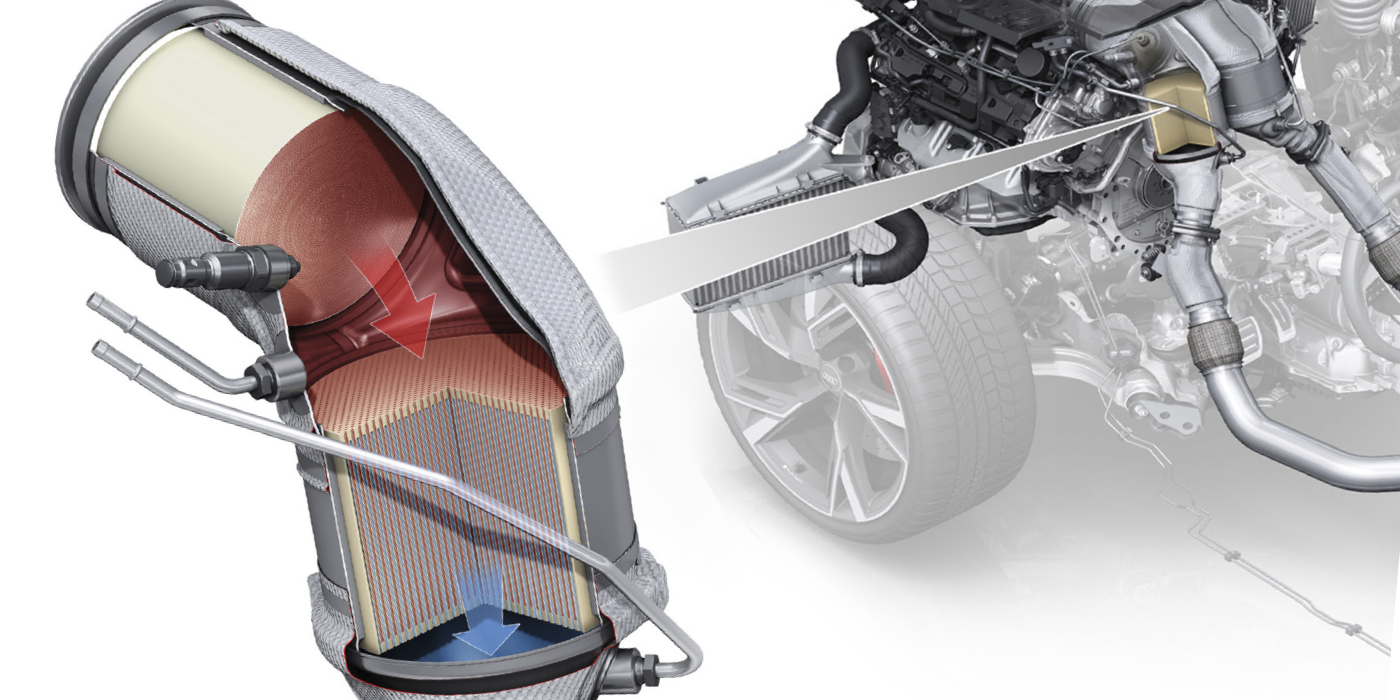

The DPF is designed to store the soot and ash, to later burn them off during a regeneration cycle.

Just like a DPF, a gasoline particulate filter (GPF) traps and stores soot particles in the exhaust stream.

As miles accumulate, O2 sensors effectively “catch a cold,” meaning they can’t breathe like they should.

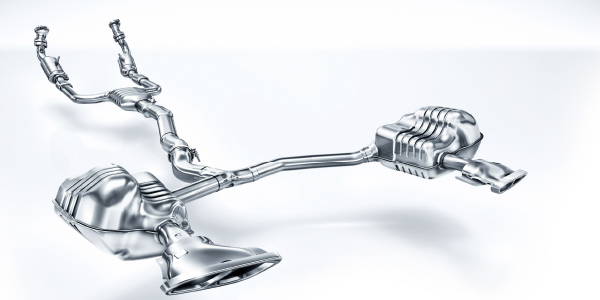

Reducing emissions to acceptable levels is achieved through a four-stage process.

To begin, an internal combustion engine creates heat energy by igniting a mixture of gasoline and atmospheric oxygen with a high-voltage spark.

The catalyst efficiency monitor verifies that the catalytic converter is operating at a high enough efficiency rating to keep exhaust emissions within predetermined values. The PCM compares the signals from the upstream and downstream oxygen sensors to determine the state of the converter. These “tests” are called the readiness monitors.