Emission systems have come a long way from the first attempts at environmental controls. The very first systems merely pulled vapor out of the tank by way of a vacuum system and fed the hydrocarbons into an activated charcoal canister system for release into the atmosphere. Now, we not only accomplish that task, but we verify the quality of the job the system is doing and the integrity of the components in the emission system.

It’s almost impossible to talk about fuel systems without getting into EVAP systems as well. EVAP codes are a very common occurrence. P0455 is one of the most common. “Gross,” meaning large, leak can be an indication of a leak or more than likely an operator error (forgetting to put the gas cap back on correctly). P0457 is the more direct code for the fuel cap not installed correctly, but either code means a large leak.

If a P0455 is set the EVAP monitoring system will shut down and not run its self-test. A secondary code is usually associated with it (DTC P1450 Unable to bleed-up fuel tank vacuum). The EVAP running loss system monitor will abort and not continue with the leak check portion of its test. If the leak is taken care of and the target vacuum has obtained the change in the fuel tank, vacuum (bleed-up) will be calculated for a calibrated period.

The calculated change in fuel tank vacuum is compared to a calibrated value preset in the PCM for a leak as small as .016 mm (.040 inch) in the EVAP system. If it is less than .016 mm, the EVAP will pass the test. If it fails, the PCM will attempt to run the monitor at least three times before setting the code again. DTC P0442 for a small leak can be hard to find. A smoke machine works well in these cases.

Most vehicles today will have a fuel tank pressure sensor, or in some cases it will be called an EVAP pressure/vacuum sensor. The FTP (fuel tank pressure) sensor is used to measure the pressure during the EVAP monitor test. When the PCM receives a signal from the FTP that there is excessive tank pressure or vacuum the PCM will then send a signal to the EVAP purge solenoid to correct the fuel tank pressure level.

These EVAP monitors can be run in two different ways. Ford, GM and some Asian imports use a vacuum to run the monitor. Chrysler, most European and a few Asian products use pressure to run the monitors. There are a lot of factors that have to be correct for the PCM to carry out the EVAP monitor. The ambient air temperature needs to be between 40 and 100 degrees for most vehicles and the fuel level needs to be near a half a full tank.

The air temperature in the tank will affect the fuel vapors. The barometric pressure must fall between 22 in. Hg on Fords and 19 in. Hg on most GM vehicles (8,000 to 10,000 feet above sea level). Most of the systems are set up to only run the test with the vehicle under 35 mph so tank slosh is kept to a minimum. The last, but most important, thing is there cannot be any other fault codes stored in the PCM. Since the job of the EVAP system is to reduce emissions, it stands to reason if there are any emission related codes stored in the PCM the eventual outcome of the EVAP test would be inaccurate.

On vehicles that use pressure to perform the EVAP monitor test, a small vacuum operated air pressure pump is used. The LDP (leak detection pump) uses vacuum to pull a small diaphragm up and down, then releases the vacuum to make its opposing chamber draw in ambient air and force that air into the fuel tank system. A small reed valve allows the air only to go in one direction which allows the internal pressure to rise in the fuel tank system. These systems are called “return-less systems” (no fuel travels back to the tank) and are widely used on most of the today’s modern cars. It’s a small amount of pressure that is applied (.25 psi or more) but it’s enough to run the EVAP monitor. The PCM has a preset calculation for the amount of bleed down time it will look for to determine the actual fuel tank pressure.

Fuel temperature sensors are quite popular now too. A fuel temperature sensor does as the name implies. The temperature is another reading the PCM will use to determine if and when it is appropriate to run the EVAP monitor.

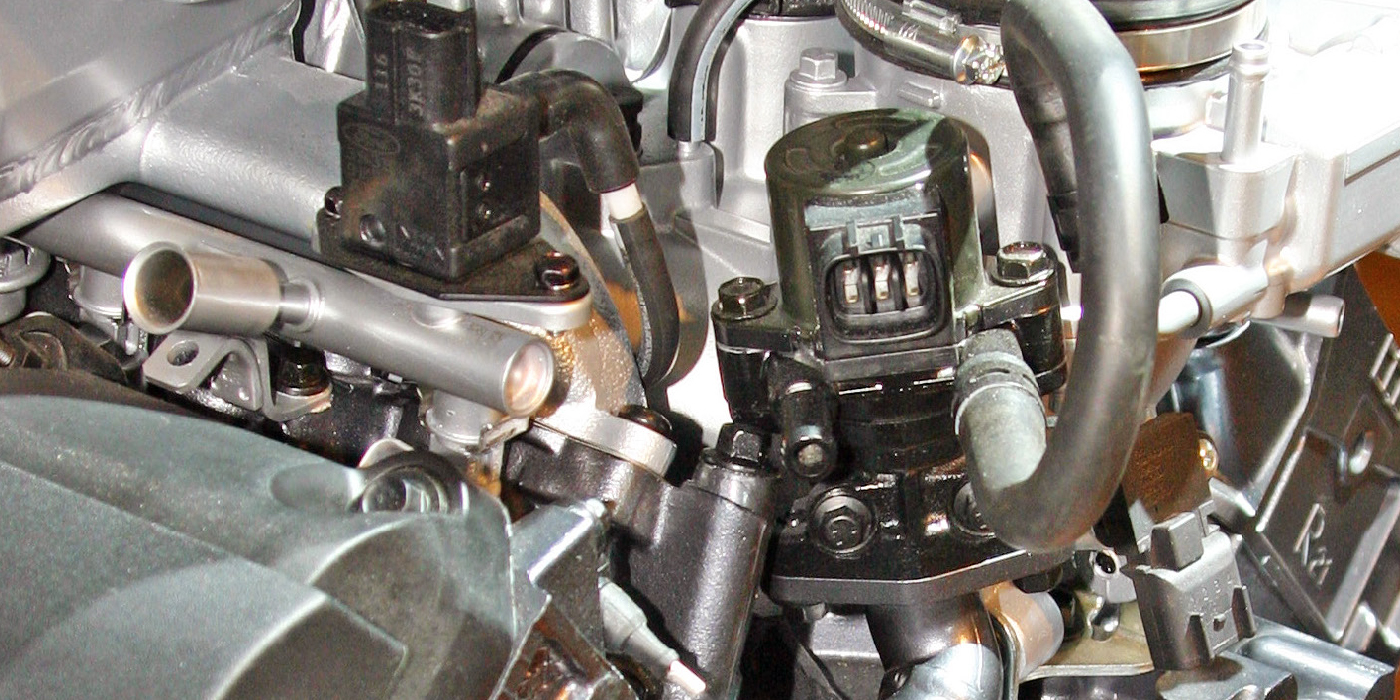

On some models, you’ll even find a fuel rail pressure sensor (FRP), this sensor is reading fuel rail pressure just as it would be with an external gauge. You can read the fuel pressure without having to hook up a fuel pressure gauge to the line. Installing a fuel pressure gauge and comparing it to the reading on the scanner is a good way of insuring the FRP sensor is reading correctly.

Before attempting any repair on a fuel system always make sure to follow the guidelines from the manufacturer. In parts of the country where high levels of salt are used for snow removal be aware that a lot of vehicles mount the charcoal canister, EVAP purge valves, and other components under the vehicle. These parts can become susceptible to failure due to corrosion from the salt or even damage from the impacted snow under the vehicle.

It’s all about having the right information. Learning the way these systems work will greatly enhance your understanding of how to repair them. In the business of automotive repair you can never know too much, and there’s always something new to learn.