The Malfunction Indicator Light (MIL) has been around for more than 25 years, but since OBD II standards made the electronic monitoring of emissions mandatory, that light has been given new life.

In Washington state, the emissions test procedure for OBD II cars makes control of the MIL an integral part of the test procedure. The fact that the MIL is on, or even commanded on, with no current code related to emissions, can be cause for a failure. The vehicle will still be scanned for codes and readiness flags will be checked, but a MIL on with the engine running will almost always spell “failure.”

In this article, I’ll stick to OBD II-equipped Mercedes-Benz vehicles built since 1995. Almost all Mercedes use similar emissions systems.

Pulling Codes

From our experience with M-Bs, most emissions-related MIL problems are centered on fuel trim failures, EGR system component faults and EVAP codes. With the adaptive capabilities of M-B engine management systems, the customer very often has no “symptom” to relate, but sees that the light is on. If a failed emissions test is involved, we can no longer just reset the light and send the customer back for a retest. Readiness flags must be set before a retest can be performed and, very often, the light won’t stay off until a long drive cycle is satisfied.

Following Diagnostic Procedures

I always try to have a plan before attacking a difficult diagnostic problem. The first step is to always understand how a particular system works and what controls it. Obviously, when there is a code that points to a specific component, say a P0135/O2S1 heater circuit malfunction, that component would be the place to start. With a scanner and the correct software, it’s quite easy to check the status of the signal to the heater circuit.

Without that test equipment, a better way to go would be to see if the power for that circuit supplies power to any other components. If there is a common power source, but only one failed component, the individual component is probably bad. In the case where there is isolated power and ground for a component, a check of the power and ground circuits to that component (at the harness connector) will confirm component or wiring problems. A DVOM or lab scope is needed for circuit tests to determine if the “correct” value is available. Of course, connector location often makes these tests difficult. A scanner with the capability of checking individual circuits is best.

On systems that operate electronically but are influenced by vacuum or pressure, a full understanding of the theory and operation is necessary for proper diagnosis, especially when a particular component is not indicated by the code like this check valve (see Photo 1).

Taking the time to understand system operation will also save a lot of diagnostic time. This step is essential before anything is disassembled or disconnected to avoid complicating the diagnosis. M-B has some rather complicated functional processes, but they make sense after a little study into how they were intended to work. Access to resistance, waveform and voltage information is especially critical to a proper diagnosis.

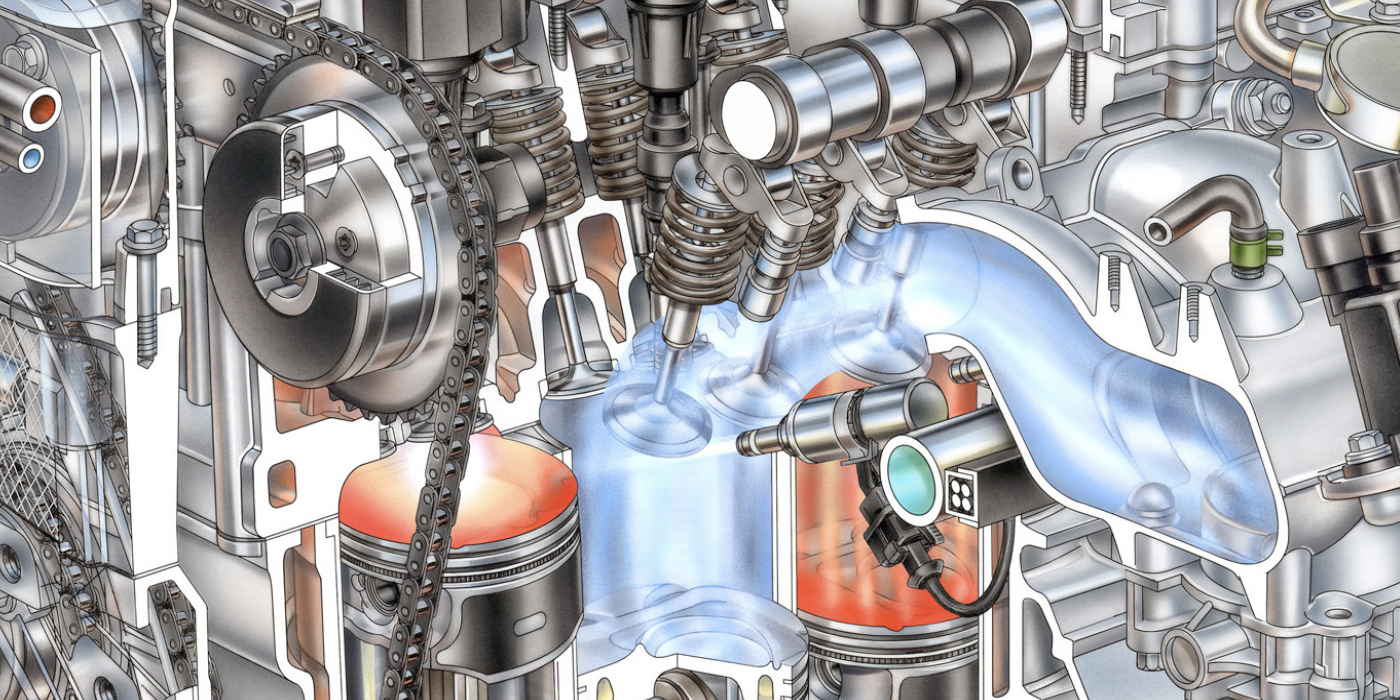

M-B has also taken a different approach to systems that would otherwise seem very “normal” in operation. For example, one of the most common questions I get on the phone is, “Where is the secondary air pump on a Kompressor model?” Do you know that M-B uses the supercharger as the secondary air pump (see Photo 2) by manipulating several control valves and sending air directly to the exhaust on a cold start?

When there are problems in this secondary air system, it results in a loss of supercharger boost. I do know of shops that have replaced the supercharger when the fault was actually in the control system.

Fuel Trim Fault Indicators

This problem is so common that, in a lot of cases, the check engine light has been on for a year with no symptoms, and customers just put up with the light until an emissions test is needed. There are so many possible causes for fuel trim to be out of range, and diagnosis can be very frustrating without a component code.

Further complicating diagnosis is the fact that some components may give no indication of a fault when tested, but in combination with other contributing factors, a fault may still exist. Be advised that like most late-model vehicles with adaptive strategies, the readings from a component may not even be the actual readings, but rather computer-generated “base” values to maintain emissions levels within a range that will prevent further damage, especially to expensive catalysts.

Fuel Trim Fault Test

Here is a good basic test process for fuel trim faults such as P0170, fuel trim malfunction:

1. Connect your scanner, making sure that all of the information relating to the proper model, engine and equipment is entered.

2. Check for specific codes and for completed readiness flags on all systems.

If any readiness parameters are not met, the data values and readings may not be correct, but adapted for best and cleanest-running condition. If there are codes, this is not the time to clear them, as doing so may dump the data (freeze frame) you will need to verify that a component has failed. Remember that the ECM can supply data that looks close to what the component should be generating.

3. Start the engine and allow it to reach full operating temperature.

4. Monitor the engine parameters as the vehicle is warming up, watching for a steady and even rise in temperature, and a corresponding increase in activity from the various sensors.

5. From my experience, probably the most important items to watch for fuel trim issues are cross counts on the O2 sensors and MAF readings that are sensitive to throttle position. If everything looks good at this point, except for fuel trim readings that are consistently positive or negative, it’s time to open the hood.

6. For fuel trim codes on M-Bs, we’ve found that a lot of the problems are due to extended service intervals. Plugged air filters, deteriorated breather or vacuum hoses and contaminated MAF sensors are always possible culprits. Removing the plastic engine cover may be all that’s necessary to spot a broken breather hose or disconnected vacuum hose.

7. Pull a spark plug to get an idea of condition, looking for obviously worn plugs, but also to get a picture of the mixture from the condition of the spark plug. A misfire can have a significant impact on fuel trim, even without setting a misfire code.

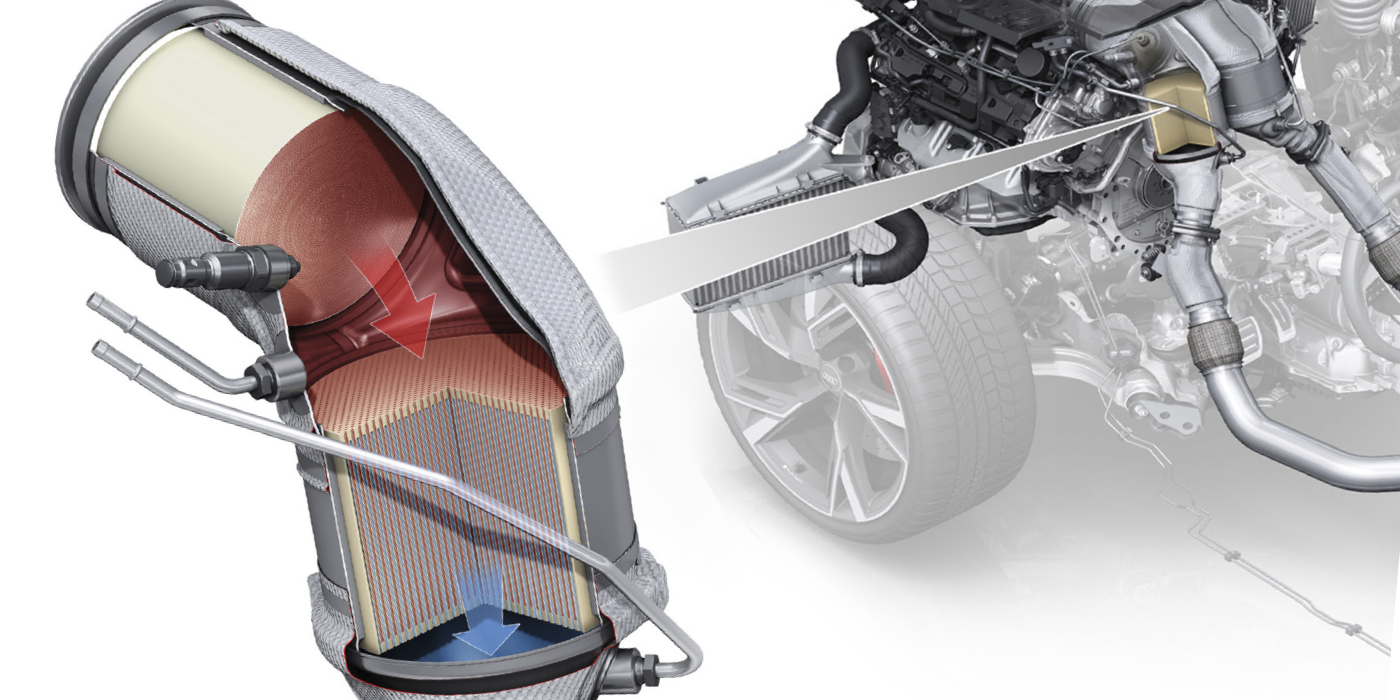

8. If you haven’t found an obvious fault by now — all of the data appears to be within normal operating parameters, there are no vacuum leaks, no exhaust leaks before the O2 sensors and the EGR system is operating properly — the most common failure we see is the MAF sensor (see Photo 3) for trim errors. Often, there is no specific code for the MAF. We’ve had excellent results with cleaning sensors with a couple of the products that are available for this purpose. Obviously, do not use just any kind of cleaner on the MAF. Even if cleaning doesn’t resolve the trim issue, the data from the sensor should change significantly.

Monitoring the EGR System

EGR systems haven’t changed much over the years, but the systems to monitor operation and flow have become much more complicated, even if the basic testing hasn’t changed much.

An emissions code like P1400, EGR valve vacuum transducer, should take you right to the valve itself; test it with a vacuum tester to make sure the diaphragm has not failed. If the valve is OK, start the engine and operate the valve to see if the engine speed drops, indicating that the ports between the exhaust and intake manifold are open. Next, inspect the vacuum supply to and from the control valve (transducer). Check the manifold vacuum to the valve and, with the engine running and throttle open, check for vacuum from the control valve to the EGR valve. These tests can be performed with a scanner with the capability to perform activations.

You can also use a two-wire harness adapter with a noid light to check that a signal to the solenoid valve is happening with everything connected. Since the EGR transducer on most V-type engines is integral with the EGR valve, the assembly is usually replaced. Due to its location on most of these cars, the valve is difficult to access at the right rear of the intake manifold. My advice is to get the corrugated steel pipe as well, as it’s sometimes brittle and will crack during removal. Also, patience is needed when removing anything plastic or rubber for access. The rubber parts will be mushy, while the plastic ones will be brittle.

EVAP Breakdowns

Codes such as P0440 to P0455 can be a nightmare on M-Bs. I’ve talked with a number of techs who dread tracking down leaks because of their complexity and hidden components (see Photo 4).

Diagnosis should start from a designated component if there is a code such as EVAP system pressure sensor malfunction, P0450. But this is where an understanding of how the pressure sensor operates and where it’s located on a particular model is important. On later models, the pressure sensor is part of the fuel sender and erratic behavior of the fuel gauge may be a clue.

As with any diagnosis, start with the basics like a missing or incorrectly installed gas cap. A smoke generator is needed to check for leaks (especially look at the seams of plastic components), but some of the components require removal of fender liners or covers to visually observe them. Looking at service history can also give you a clue. For example, removing the plastic engine cover to replace air filters may have dislodged a vacuum source or purge line.