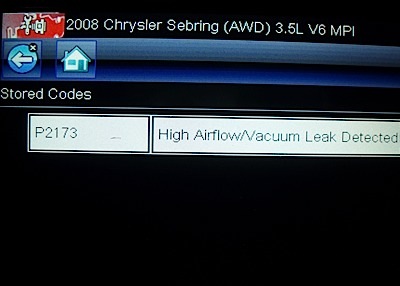

In this month’s Diagnostic Dilemma, I found myself looking into an intermittent fast idle complaint on a 2008 Chrysler Sebring equipped with the 3.5L, V6 engine. The car was in good condition and with approximately 130,000 miles on the odometer. My client shop owner had retrieved some “throttle sensor codes,” which prompted him to replace the electronic throttle body. The codes hadn’t been recorded and were lost to memory. After connecting my scan tool, I found a P2173 DTC. Since the P2XXX designation indicates an OE code, I went to OE service data to determine the conditions under which the P2173 code would set. I also highlighted a notation saying, “This DTC is enabled on engines equipped with a plastic intake manifold to limit operation if a large vacuum leak should occur.”

The relevance of that notation didn’t dawn on me until late in the diagnostic process.

According to service data, the test monitor will run with the ignition on and with no manifold absolute pressure (MAP) sensor DTCs. According to the enabling or “set” criteria, a large vacuum leak had been detected or the signal voltage for both throttle position (TP) sensors is stuck at 2.5 volts “and calculated MAP is less than the gas flow adaptation value.”

Continuing on, the P2173 DTC is a one-trip fault, and the DTC will set within five seconds of the failure and the electronic throttle control (ETC) warning light will flash. Possible causes include a vacuum leak, open-circuit MAP sensor, shorted or high resistance wiring, a bad MAP sensor, a stuck-open EGR valve, or a bad powertrain control module (PCM).

STROLLING DOWN PRIMROSE LANE

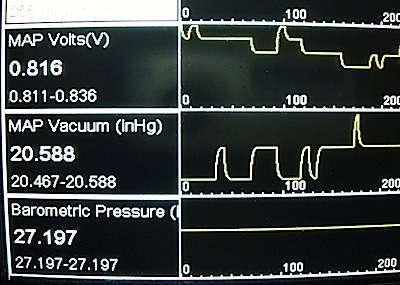

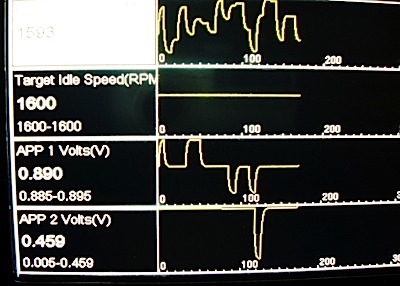

According to the shop owner, the fast idle condition would occur 15 minutes after the engine had been started. If the engine were turned off and restarted, it would run normally for another 15 minutes before setting the P02173 DTC. After starting the engine, the fuel trims were correct, as were all other engine PIDs. After 15 minutes run time, the engine idle speed instantly jumped to exactly 1,600 rpm and the oxygen sensors indicated a severe lean condition. In addition, the engine sounded rough and noisy.

At this point, I’m thinking we’re into a default operating strategy for the electronic throttle, so I began graphing the TP 1, TP2, APP1, and APP2 voltages. As I discovered, the APP2 was randomly dropping from about 0.500 volts to nearly zero, then recovering. Since a variation of 0.454 volts might not be enough to set a DTC, I let the ETC voltage issue ride for now.

Going back to the large vacuum leak, I tested the evaporative purge system with no result and watched for a change in oxygen sensor voltage as I applied my propane leak detector to intake gaskets and vacuum hoses.

After five minutes of testing, I concluded that there was not a major external vacuum leak despite the fact that the scan tool indicated a severe lean condition. At this point, any major disassembly or inspection of the vehicle was precluded by the customer needing his car for a doctor’s appointment several hours later. And, quite frankly, I had run out of ideas.

SORTING THE DATA

The most baffling part of the diagnosis were the DTCs indicating a major vacuum leak and the voltage drop on the APP2 graph. In most cases, voltage fluctuations in the electronic throttle assembly will store an applicable DTC. After pondering the data, I began thinking that the P2173 DTC or major vacuum leak might prevent the electronic throttle control (ETC) from storing a DTC. So, possibly, I have a vacuum leak and an ETC failure? Where to start?

This Diagnostic Dilemma revolved around how a vacuum leak could simultaneously be so large and so intermittent. According to my understanding of diagnostics, the only two sources that could produce an intermittent vacuum leak of that magnitude would perhaps be a sticking purge valve or a disconnected vacuum brake booster hose. Keeping the erratic APP2 voltage in mind, I decided that we had to first diagnose the major vacuum leak before we could address the ETC problem, which means I’m back to redoing my propane leak test and hoping for a little bit of luck.

HITTING THE CURVE BALL

One week later, the vehicle owner appeared for his second appointment. While he reported no new fast-idle problems, the engine immediately went into its fast idle condition as soon as the car was started and driven into the shop. After hurriedly connecting my scan tool, I discovered that, as before, the engine was running exactly at 1,600 rpm, under a very lean operating condition. The engine was also rough and noisy, with APP2 dropping voltage as before.

To complicate matters, the owner was watching my whole diagnostic process. So after completing my propane test, I was left staring at the confusing data on my scan tool. Just to be sure, I again plugged the power brake vacuum nipple, which didn’t affect the 1,600 rpm idle speed or the lean condition.

During this fruitless test session, the owner struck up a conversation about how he had loaned his car to his daughter for one month in a city 125 miles away. For whatever reason, his daughter and her friends decided to install a speaker system in the car and, although the speaker system had since been removed, the car had returned with this intermittent fast-idle problem.

I carefully listened to his story and tried to make sense of it. How could installing a speaker system cause a P2173 major vacuum leak and an intermittent drop in APP2 voltage? How could a speaker installation create both a mechanical and an electrical problem?

The owner’s narrative threw a real curve ball at my diagnostic scenario. Pondering these issues, I went about my scan tool diagnostics until I noticed a perfect APP2 signal, which threw still another curve ball at my diagnostic scenario. Clearly, I’m not hitting the ball out of the park on this Chrysler Sebring.

THE OWNER INTERVIEW

Previous to our conversation, I had noticed a small red ETC warning light on the instrument panel and wanted to verify its purpose. According to the owner’s manual, the ETC warning light indicated a fault with the electronic throttle control system. Further, the manual indicated that the engine would operate in a “reduced performance mode” when the ETC warning light was illuminated. With that information in hand, I questioned the owner about his Chrysler’s performance. It turned out that “sometimes it didn’t run very well and sometimes his brakes didn’t seem to want to stop the car.” Here was still more information that I hadn’t received during my initial visit.

But back to the mysterious disappearance of the APP2 voltage drop. Fortunately, the shop owner was available on this very busy day to help me diagnose the APP2 voltage problem. I asked him to go under the dash panel and tap on the APP assembly while I watched for fluctuations in APP voltage. With some effort, my client accessed the APP assembly under the tightly packed dash and tapped on it with his screwdriver. Again, the APP2 voltage was perfectly stable.

Looking under the tight dash with his flashlight, my client shouted, “Holy cow, look at this!” The “this” turned out to be two feet of black electrical tape wrapped around the APP assembly wiring harness. After pulling the tape off the wiring, my client examined the wires as best he could, but could find no damage. My immediate question was, “Why would an amateur mechanic attempt to connect a speaker system to the APP wiring harness?”

Due to lack of visibility, my owner client handed me his new bore scope tool and asked me to watch for scraped wiring while he waved the wand around the APP wiring harness. Immediately, I spotted a 1/2-in hole drilled through the firewall. I asked my client if he could see the hole through the firewall. He could, but barely.

He then inserted a finger through the hole and let out another war whoop. “Holy cow,” he exclaimed. “Somebody drilled a hole through the back of the brake booster!” Instantly, all of the bits of accumulated data, including the P2173 DTC setting conditions, the alleged connection between the speaker installation and the fast-idle complaint, the mysteriously intermittent major vacuum leak, and the equally mysterious erratic APP2 voltage came together into a single rational failure scenario.

LESSONS LEARNED

In years past, we would compare short-term and long-term bank-to-bank fuel trims, and other times we’d look at total fuel trims. Most recently, we’re looking at more downstream oxygen sensor fuel trims. But in the case of this fast-idling 2008 Chrysler Sebring, none of those diagnostic methods held true. First, the 1,600 rpm fast idle wasn’t an operating condition, but rather an operating strategy programmed into the PCM to deal with a major vacuum leak. Remember the mysterious statement on my original print out: “This DTC is enabled on engines equipped with a plastic intake manifold to limit operation if a large vacuum leak should occur.” No doubt, this is an engineer’s way of saying that the PCM will react to a major vacuum leak by 1) increasing the engine speed to exactly 1,600 rpm, 2) leaning out the air/fuel mixture, presumably to compensate for a loss of MAP values, and 3) perhaps advancing the spark timing to burn the lean a/f mixture, which results in the engine becoming slightly rough and noisy. The operating strategy is apparently designed to maintain adequate intake manifold at the brake booster when a large vacuum leak is detected and also to limit ETC operation.

As for the brake booster, the actual diameter of the hole was about ¼ inch. With most vacuum brake booster designs, the pushrod from the brake pedal is connected to a metering valve that bleeds vacuum into a chamber containing a rubber diaphragm. Atmospheric pressure then pushes against the diaphragm to increase pedal assist. To test this theory, I turned the ignition off to “reset” the PCM. After starting the engine, it idled perfectly, no matter what position in which I held the brake pedal. We could feel a vacuum leak at the hole drilled into the booster, but nothing showed in the data PIDs to indicate a vacuum leak. Pumping the brake pedal or holding it halfway down had no effect. So, I’m speculating that the fast-idle condition would only occur when the pedal was in a particular position for a length of time, such as a long period of braking downhill — so much for the DTC setting within five seconds of the failure.

The new booster required about 10 days to locate and deliver. After installation, the engine ran perfectly and the Chrysler was delivered to its owner. Although I’m still concerned that we might have a short-to-ground problem with the APP wiring harness, none has appeared since the two feet of black electrical tape was removed.

The Lesson Learned on this Chrysler Sebring is that with greatly increased computing capacities now available, auto manufacturers are programming alternative operating strategies into their PCMs to deal with operational problems like major vacuum leaks. So, when you’re dealing with a Chrysler P2XXX-series DTC, don’t forget that the “symptoms” might actually be an “operating strategy” designed to deal with a particular component malfunction or operating condition.